0

0

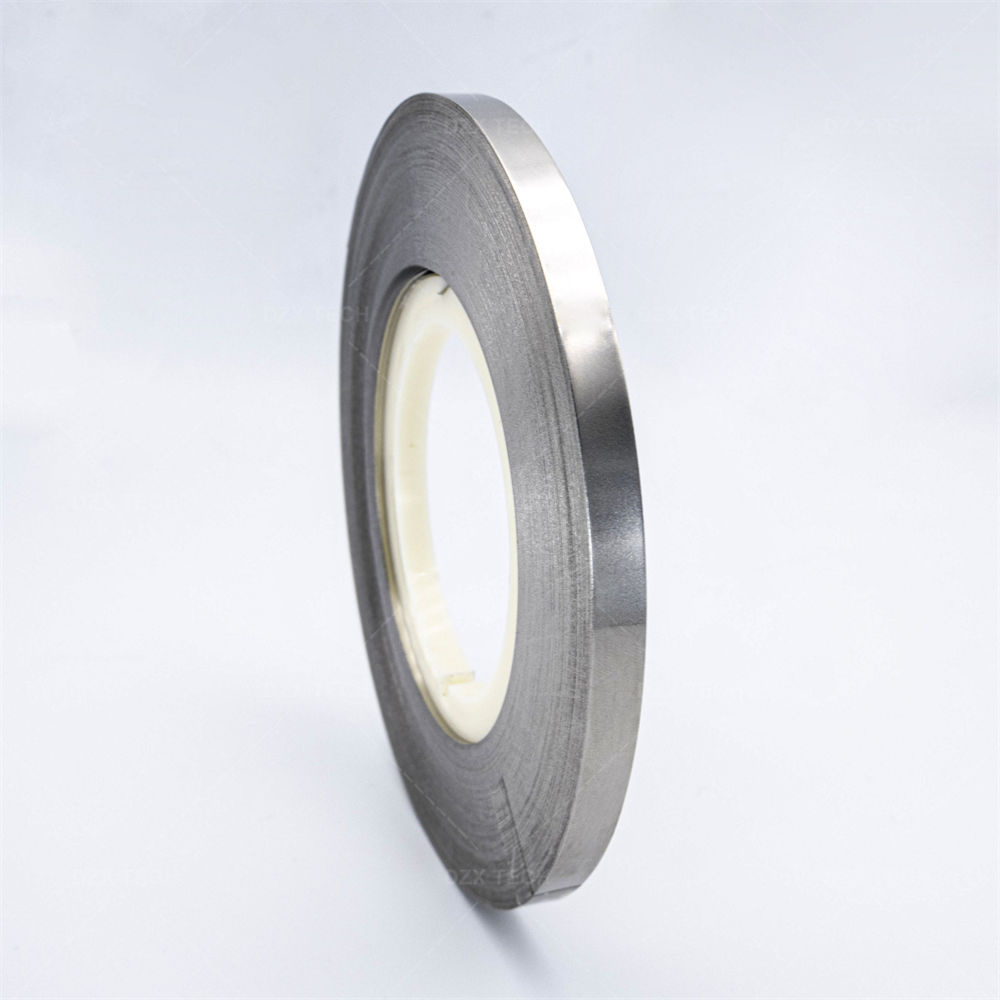

Products Description

Inconel strips are also widely used in the chemical and petroleum industries. Inconel is a nickel-based alloy that offers excellent corrosion resistance and high-temperature strength for applications operating in harsh chemical environments and high-temperature conditions.

In the chemical industry, many chemical processing processes involve high temperatures, high pressures and corrosive media. Inconel strips are widely used in the manufacture of equipment such as reactors, heat exchangers, catalyst pipes and storage tanks due to their excellent corrosion resistance. It can resist the erosion of corrosive media such as acidic, alkaline and salt solutions, providing reliable anti-corrosion protection while maintaining good mechanical strength and structural stability under high temperature conditions.

In the petroleum industry, Inconel strip plays an important role in oil wells and refining processes. It can be used to manufacture corrosion-resistant oil well pipes and casings, which can resist the erosion of acidic, high-temperature and corrosive media in oil wells. In addition, Inconel strips are also widely used in equipment such as distillation towers, reactors and catalyst pipelines in refineries, as well as storage tanks and pipeline systems in liquefied natural gas (LNG) processes.

Physical property

Chemical composition: Nickel (≥58%), Chromium (≤23%), Iron (≤1%), Aluminum (≤1%), Silicon (≤0.5%)

Density: 8.11 g/cm³

Melting point: 1,370°C (2,498°F)

Tensile strength: 550 MPa (minimum)

Yield strength: 240 MPa (minimum)

Elongation: 30% (minimum)

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Characteristic:

Corrosion resistance: Inconel strips perform well in chemical media, acidic environments and high temperatures. They have excellent corrosion resistance and can withstand the erosion of corrosive media in the chemical and petroleum industries.

High temperature performance: Inconel strips can maintain good strength and stability under high temperature conditions and are suitable for applications such as high temperature reactors, furnace tubes and heaters.

Oxidation resistance: Inconel tape can resist oxidation in oxidizing environments and high temperatures, and has excellent antioxidant properties, helping to extend the service life of equipment.

Creep Resistance: Inconel tape has good creep resistance and is able to maintain shape and stability under high temperature and high stress conditions.

Specific applications:

Chemical Reactors: Inconel tape can be used to manufacture components such as linings, heating tubes and heat transferors for chemical reactors to provide corrosion resistance and high temperature performance.

Petroleum processing equipment: Inconel strips are widely used in petroleum processing equipment, such as distillation towers, heat exchangers and catalyst tubes, etc., to handle high temperature and corrosive media.

Oil Drilling: Inconel strips can be used in the corrosive environments found in oil drilling to manufacture high temperature and corrosion resistant pipes and tools.

Q&A:

Q: What is the corrosion resistance of Inconel strips in the chemical industry?

A: Inconel strips have excellent corrosion resistance and can resist corrosion from chemical media, acidic environments and high temperature conditions. They are suitable for manufacturing corrosion-resistant parts in the chemical industry.

Q: What is the high temperature performance of Inconel strip in the petroleum industry?

A: Inconel strips have good high-temperature strength and stability and are suitable for manufacturing high-temperature equipment and components in the petroleum industry, such as distillation towers and heat exchangers.

Q: What are the applications of Inconel strips in oil drilling?

A: Inconel strips can be used in corrosion-resistant environments in oil drilling and are used to manufacture pipes, tools and equipment under high temperatures and corrosive media.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China