0

0

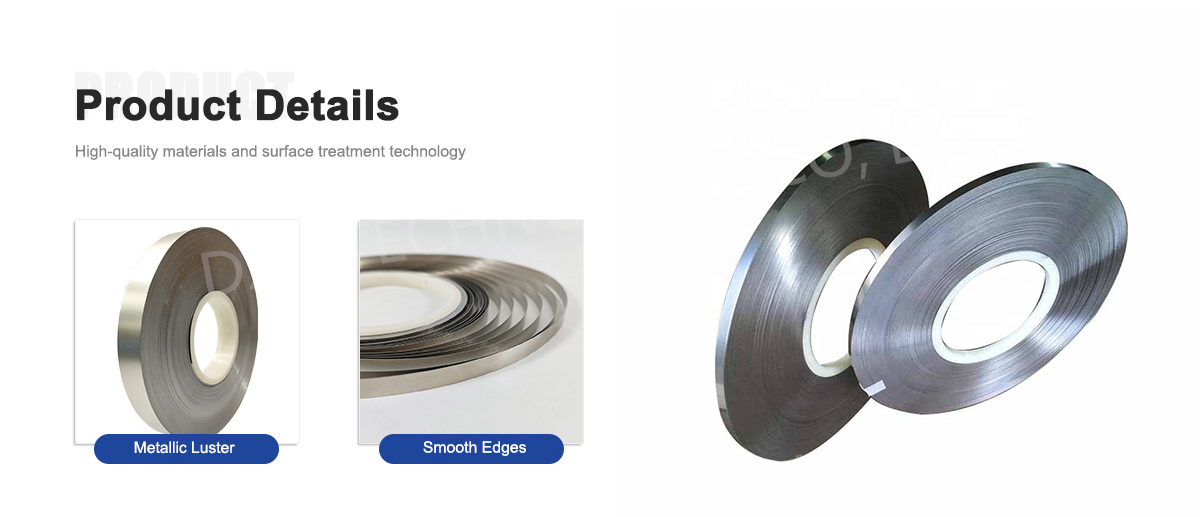

Products Description

ASTM hot rolled inconel 600 625 718 800 nickel alloy strip

Inconel X750 UNS N07750 is an age-hardenable Alloy-chromium alloy. It has good corrosion and oxidation resistance and high strength at temperature up to 700℃. It also has good properties down to cryogenic temperatures. Its corrosion resistance performance is similar to Inconel 600.

Character

• Ending machinability

• Low at 700 ℃ has high tensile strength, fatigue strength, creep strength and fracture strength

• Low at 1000 ℃ has the high oxidation

• Both ends have stable chemical properties at low temperature

• Ending with good welding performance

Physical property

Density: ρ=8.28g/cm3

Melting temperature range: 1393-1427℃

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

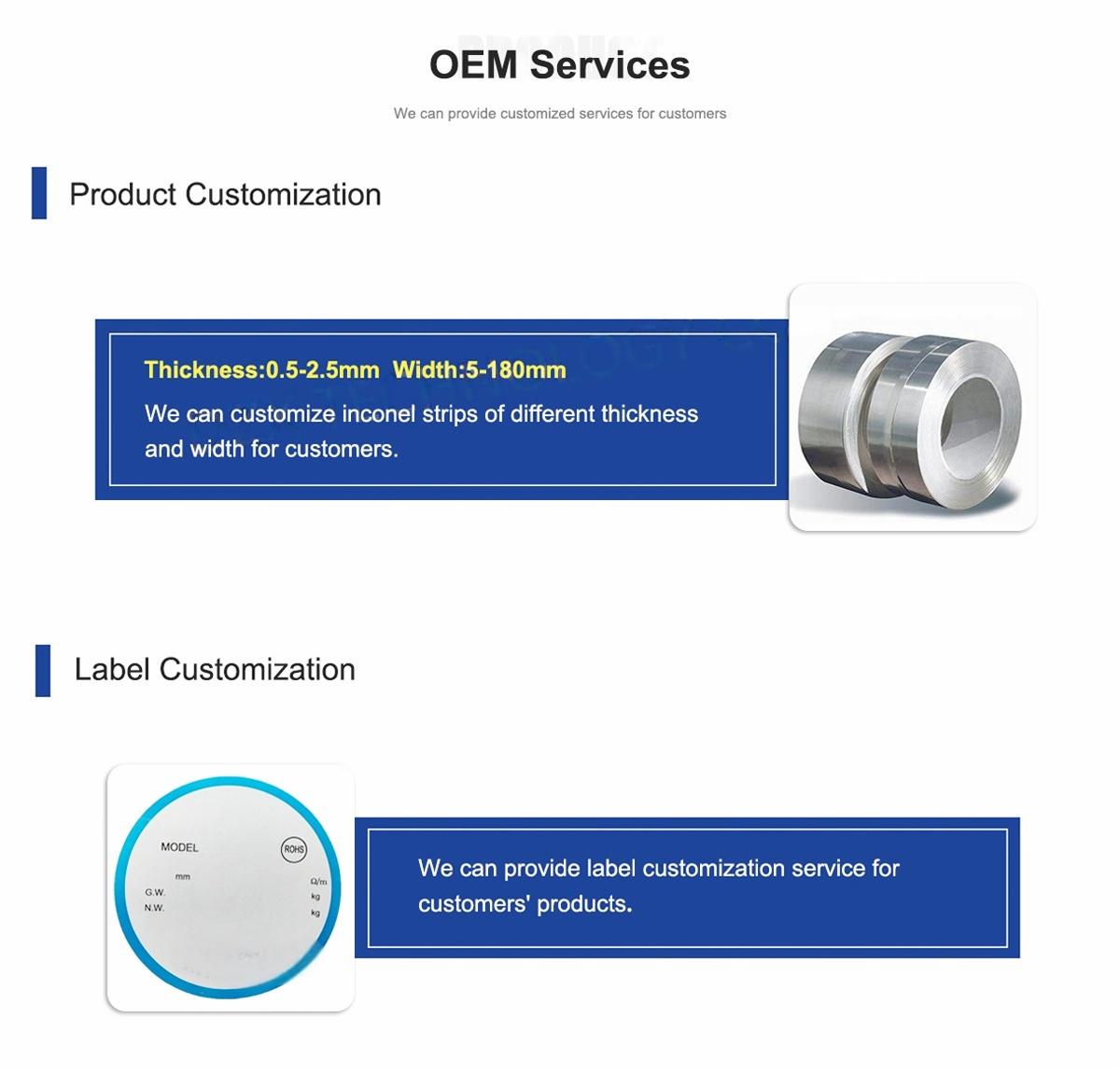

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Feature

High Temperature Resistance: Inconel alloys retain their strength and mechanical properties at elevated temperatures, making them suitable for applications in extreme heat environments. They can withstand temperatures ranging from cryogenic levels up to 2,000 degrees Fahrenheit (1,093 degrees Celsius).

Corrosion Resistance: Inconel strip exhibits excellent resistance to corrosion, both in acidic and alkaline environments. It is highly resistant to oxidation, reducing conditions, and chloride-induced stress corrosion cracking. This property makes it suitable for applications where exposure to harsh chemicals or corrosive environments is a concern.

Mechanical Strength: Inconel alloys have high tensile strength and excellent mechanical properties, even at elevated temperatures. They offer good fatigue resistance, creep strength, and toughness, making them suitable for demanding structural applications.

High-Stress Applications: Inconel strip can withstand high levels of mechanical stress, including cyclic loading and thermal cycling. It finds application in industries such as aerospace, gas turbines, nuclear power plants, and chemical processing, where components are exposed to extreme conditions and mechanical stress.

Dimensional Stability: Inconel strip exhibits good dimensional stability over a wide temperature range. It has a low coefficient of thermal expansion, which means it expands and contracts less with temperature changes compared to other materials. This property is crucial for maintaining precise tolerances in various applications.

Fabricability: Inconel strip can be easily formed, machined, and welded using conventional methods. It can be cold-rolled to achieve the desired thickness and shape without sacrificing its mechanical properties.

Magnetic Permeability: Inconel alloys have a low magnetic permeability, which means they are non-magnetic in most conditions. This property makes them suitable for applications where magnetic interference or distortion should be minimized.

Application

Aerospace industry: Inconel strip is widely used in high-temperature components such as jet engines, turbine blades, combustion chambers and gas turbines in the aerospace field. Its ability to withstand extremely high temperatures and stresses while having excellent corrosion resistance makes it ideal for use in the aerospace industry.

Chemical and Petroleum Industry: Due to its excellent corrosion resistance, Inconel strip is widely used in high temperature, high pressure and corrosive environments in the chemical and petroleum industries. It is used in the manufacture of chemical reactors, distillation towers, petroleum refining units and chemical processing equipment, etc.

Nuclear industry: Inconel strip also plays an important role in the nuclear industry and is used in components such as fuel tubes, coolant circuits and nuclear fuel storage containers in nuclear reactors. Due to its radiation resistance and high temperature performance, it is able to maintain structural integrity in extreme nuclear environments.

Heat treatment and high temperature processing: Inconel strip is widely used in the fields of heat treatment and high temperature processing due to its excellent high temperature strength and oxidation resistance. It is used to manufacture equipment such as high-temperature furnaces, vacuum furnaces, molten metal vessels, and high-temperature heating elements.

Medical devices: Inconel strips are also used in the medical field, especially in artificial joints and implantable devices. Due to its biocompatibility and anti-corrosion properties, it is able to withstand the challenges of the human environment and provide reliable support and durability.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China