0

0

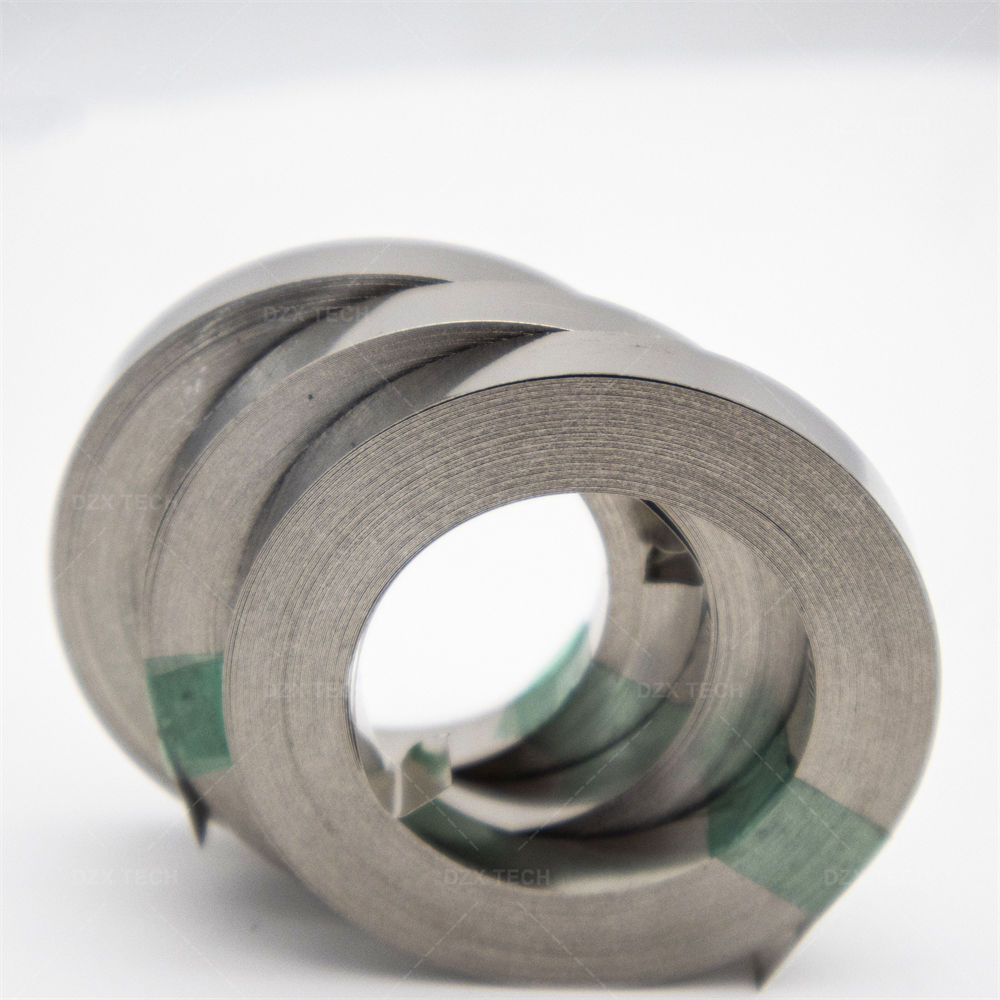

Products Description

Inconel strip is a high-performance alloy strip with a wide range of applications in various fields. Its main components are nickel and chromium, and also contains other alloying elements such as iron, titanium and aluminum. Inconel tape is known for its excellent resistance to high temperatures, corrosion and oxidation.

Due to its excellent high temperature strength and corrosion resistance, Inconel strip is widely used in aerospace, energy, chemical, petroleum and nuclear industries. In the aerospace field, Inconel strips are often used to manufacture jet engine parts, combustion chamber components and turbine blades to cope with extreme environments of high temperature, pressure and corrosion. In the energy field, Inconel strips are used to manufacture gas turbines, nuclear power equipment, and oil drilling equipment to ensure stable operation of equipment in high temperatures and corrosive media. At the same time, in the oil mining and refining process, Inconel strips are also used to manufacture pipes, valves and equipment to ensure safe and efficient operations.

In short, Inconel strip, as a high-quality, high-performance alloy strip, plays an important role in aerospace, energy, chemical, petroleum and nuclear industries. Its excellent high temperature resistance, corrosion resistance and oxidation resistance make it an ideal choice under various extreme working conditions, providing reliable solutions for processes and equipment in various industries.

Physical property

Chemical composition: Nickel (≥58%), Chromium (≤23%), Iron (≤1%), Aluminum (≤1%), Silicon (≤0.5%)

Density: 8.11 g/cm³

Melting point: 1,370°C (2,498°F)

Tensile strength: 550 MPa (minimum)

Yield strength: 240 MPa (minimum)

Elongation: 30% (minimum)

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Characteristic:

High temperature stability: Inconel strips can maintain stability and strength under high temperature conditions and are suitable for high temperature working environments.

Corrosion resistance: Inconel strips have good corrosion resistance to acidic and alkaline media and can be used in corrosive environments.

High Strength: Inconel tape has high strength and durability, able to withstand stress and load, maintaining shape and function.

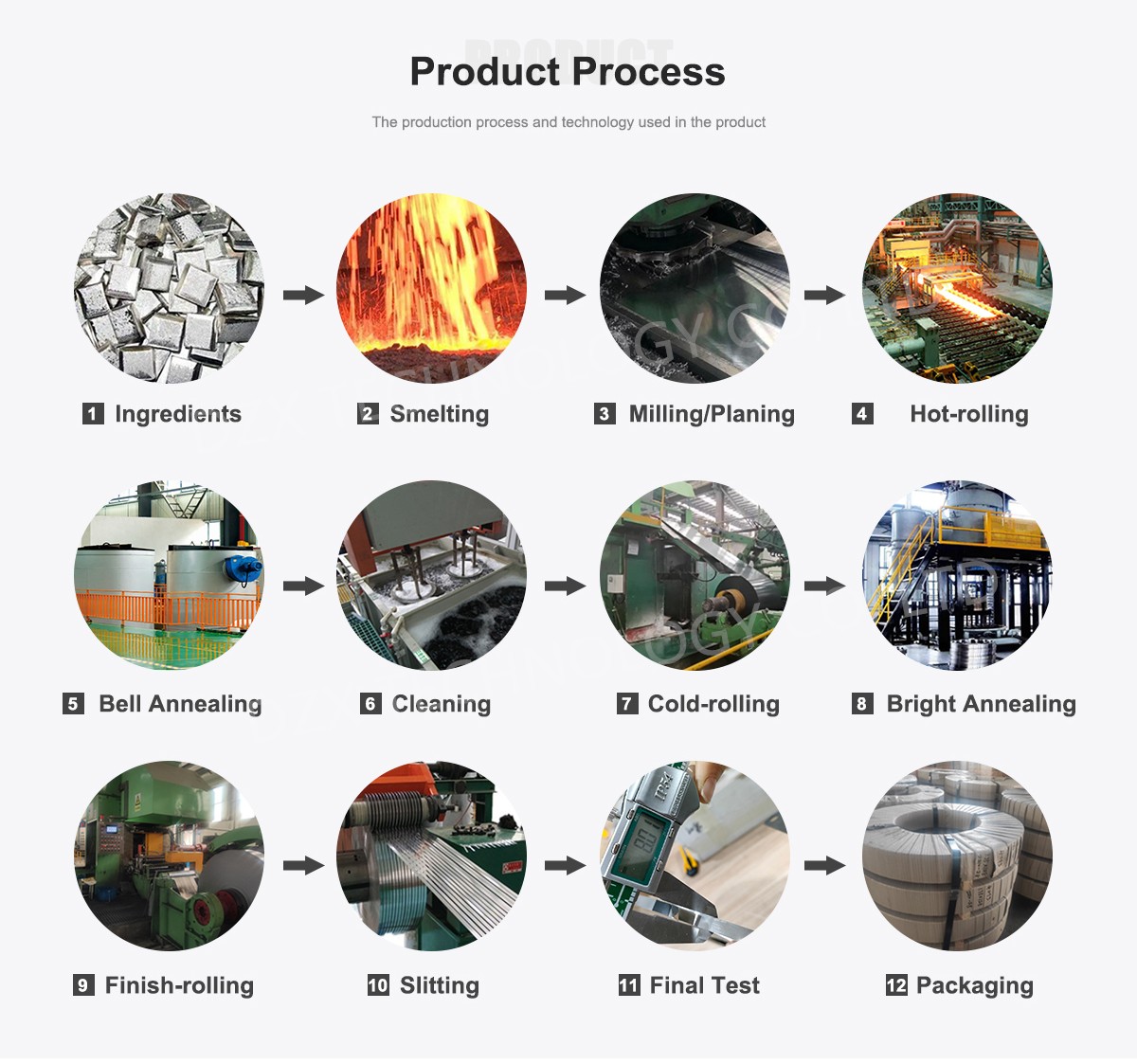

Production process:

The production process of Inconel strips usually includes the following steps:

Raw material preparation: Select the appropriate Inconel alloy material, and cut and process the raw materials.

Smelting and Casting: The raw materials are heated to the melting point and smelted and cast into strip form.

Hot rolling and cold rolling: The strip obtained by smelting is hot and cold rolled to achieve the required thickness and width.

Surface polishing and annealing: Surface treatment and annealing are performed on the cold rolled strip to improve the performance and quality of the material.

Cutting and shaping: According to customer needs, the strip is cut to the required size, and edge shaping and flatness control are performed.

Surface treatment: Surface treatment of strips, such as pickling, polishing, etc., to improve appearance and corrosion resistance.

Final inspection: Conduct final quality inspection on the finished strip, including testing of dimensions, chemical composition, physical properties, etc.

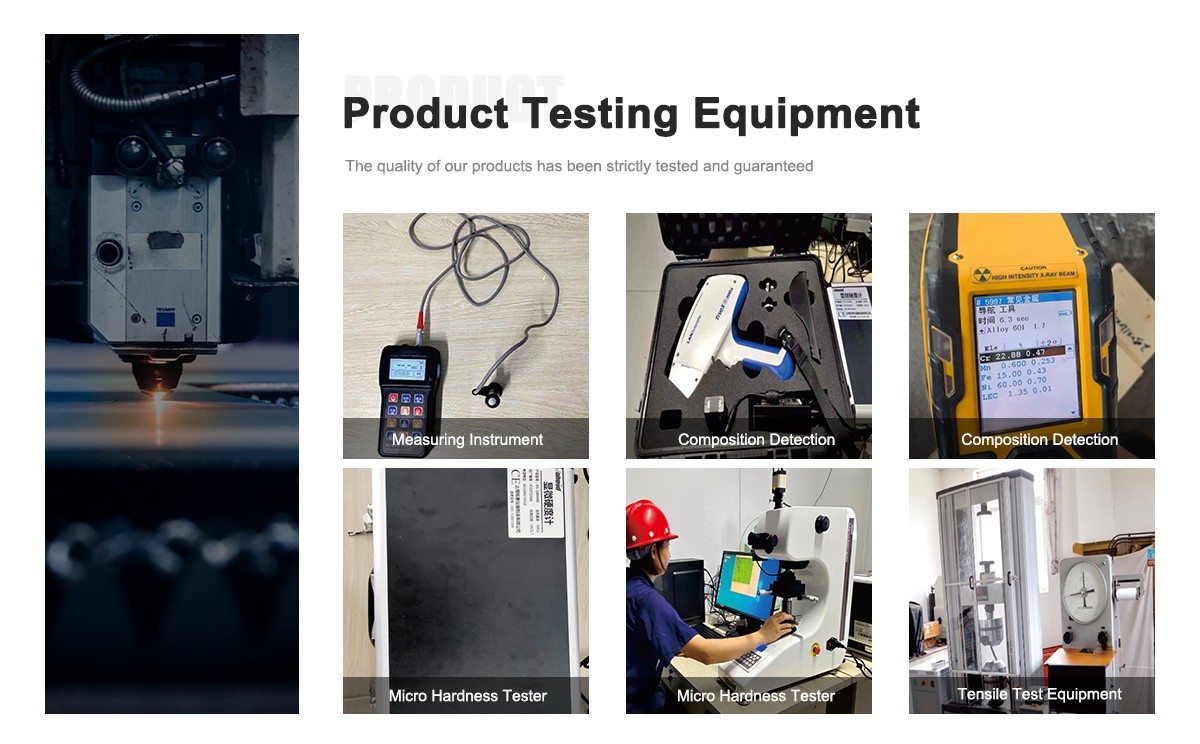

Quality Inspection:

Quality inspection of Inconel strips usually includes the following aspects:

Dimensional inspection: Measure the thickness, width, length and other dimensional parameters of the strip to ensure that it meets the specified requirements.

Chemical composition analysis: The content of each element in the strip is detected through chemical analysis methods to verify whether the alloy composition meets the standards.

Physical performance testing: including tensile strength, yield strength, elongation and other tests to evaluate the mechanical properties and reliability of the strip.

Q&A:

Q: Which steps in the production process of Inconel strips have a greater impact on quality?

A: The steps in the production process such as smelting and casting, hot rolling and cold rolling, annealing and final inspection have a greater impact on the quality of Inconel strips. The key is to ensure that the alloy composition, size and physical properties meet the requirements.

Q: What are the quality inspection methods for Inconel strips?

A: The quality inspection methods of Inconel strips include dimensional inspection, chemical composition analysis and physical performance testing. These tests ensure that the strip's dimensional accuracy and chemical composition meet requirements, and verify its mechanical properties and reliability.

Q: What are the surface treatment methods for Inconel strips?

A: The surface treatment methods of Inconel strips include pickling, polishing, mechanical treatment, etc. Pickling can remove oxides and dirt on the surface of the strip and improve its corrosion resistance; polishing can make the surface smooth and bright, improving the appearance quality; mechanical treatment can improve the roughness and flatness of the surface through sand brushing or shot blasting. . These surface treatments help improve the performance and service life of Inconel tape.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China