0

0

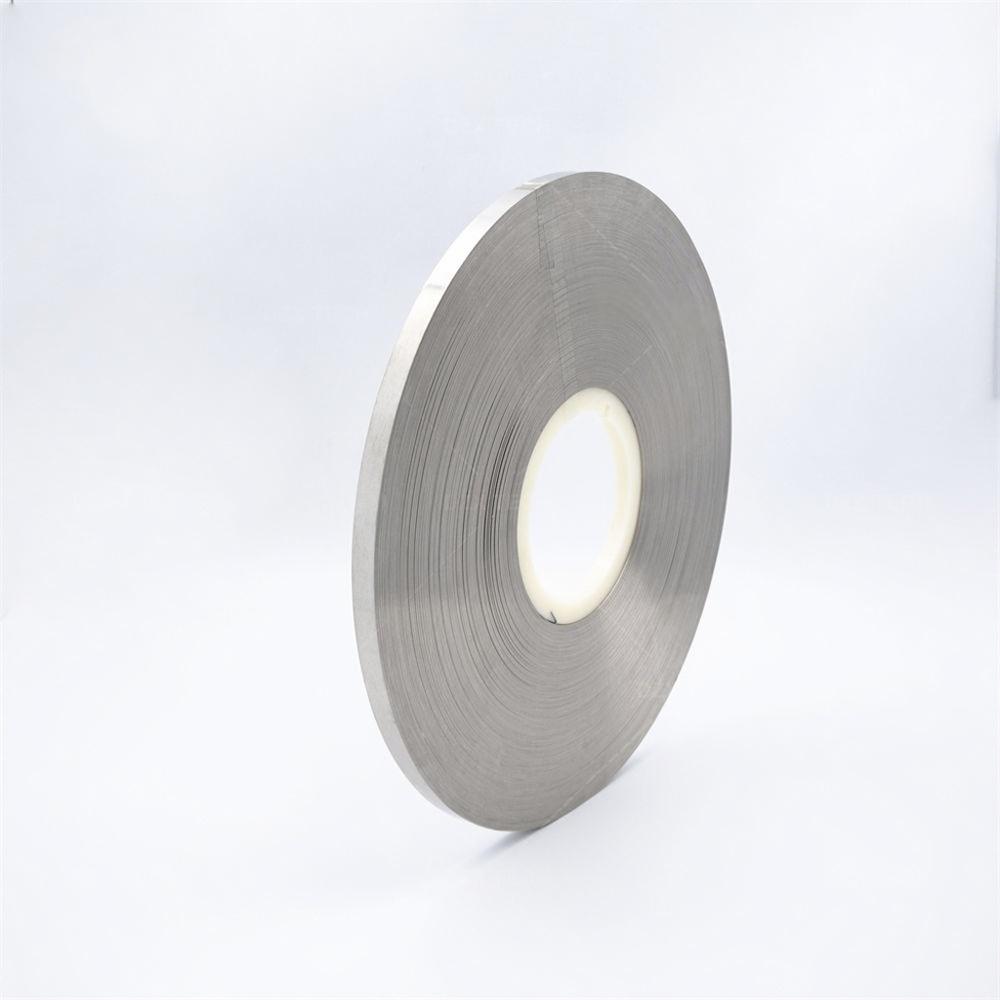

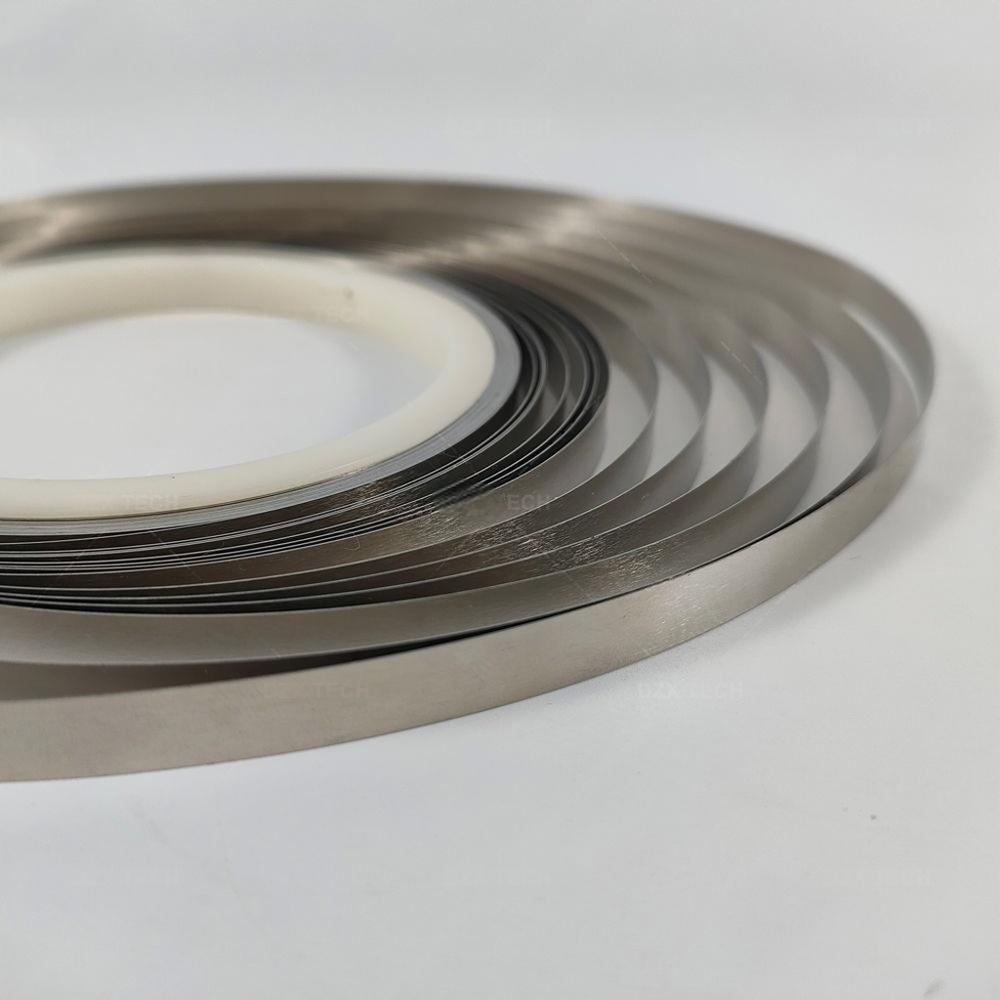

Products Description

Inconel 601 strip is a high-temperature alloy strip mainly composed of elements such as nickel, chromium and iron. It has excellent high temperature oxidation resistance, corrosion resistance and high strength properties. Inconel 601 tape performs well in high temperature environments and is able to withstand the effects of high temperature oxidation, sulfide corrosion and thermal cycling. It is widely used in petrochemical industry, oil refining, burners, stoves and heat treatment equipment and other fields. Inconel 601 tape is also used in the aerospace industry to manufacture high-temperature parts and engine components. Its excellent corrosion resistance and high temperature stability make it an ideal material choice to provide reliable performance and durability in extreme environments.

Physical property

Chemical composition: Nickel (≥58%), Chromium (≤23%), Iron (≤1%), Aluminum (≤1%), Silicon (≤0.5%)

Density: 8.11 g/cm³

Melting point: 1,370°C (2,498°F)

Tensile strength: 550 MPa (minimum)

Yield strength: 240 MPa (minimum)

Elongation: 30% (minimum)

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Characteristic:

High-temperature oxidation resistance: Inconel 601 strip can form a dense oxide layer in high-temperature environments, effectively preventing oxidative corrosion.

Good corrosion resistance: It has excellent corrosion resistance against corrosive media such as acid, alkaline and chloride.

High Temperature Stability: Inconel 601 strip has good structural stability and mechanical properties at high temperatures and is able to resist stress and deformation caused by thermal cycling.

Resistance to sulfide corrosion: It can withstand the erosion of sulfide corrosive media and is suitable for applications in sulfur-containing environments.

Compared:

Inconel 601 strip exhibits excellent corrosion resistance, especially in high-temperature environments, which is one of its key advantages. When compared to other high-temperature alloys, such as Inconel 600 and Inconel 625, Inconel 601 offers superior resistance to oxidation, scaling, and aqueous corrosion.

Inconel 601 has a higher chromium content than Inconel 600, which enhances its resistance to oxidation and sulfur-related corrosion. It forms a protective oxide layer when exposed to high temperatures, preventing further oxidation and degradation of the material. This makes it suitable for applications involving combustion environments, furnace components, and thermal processing equipment.

Compared to Inconel 625, Inconel 601 has better resistance to oxidation at high temperatures. While Inconel 625 offers excellent corrosion resistance in various environments, including acidic and chloride-containing conditions, Inconel 601 performs better in oxidizing atmospheres and sulfur-bearing environments.

It's important to note that the specific corrosion resistance of any alloy depends on the particular corrosive environment, temperature, and exposure conditions. Proper material selection should consider the specific requirements of the application to ensure optimal performance and longevity.

Application:

Heat Treatment Equipment: Inconel 601 strip is widely used in the manufacturing of high-temperature furnace components, such as radiant tubes, muffles, and baskets. It provides excellent thermal stability and resistance to oxidation and carburization, making it ideal for heat treatment processes.

Petrochemical Industry: Inconel 601 strip is employed in various petrochemical applications, including reformer tubes, catalyst grid supports, and thermocouple sheaths. Its resistance to high-temperature oxidation, sulfur compounds, and corrosive gases makes it suitable for harsh operating conditions in refineries and chemical plants.

Aerospace Industry: Inconel 601 strip is utilized in aerospace applications that require high-temperature performance. It is commonly used in gas turbine components, such as combustion chambers, transition ducts, and exhaust systems. The alloy's capability to withstand thermal cycling and its resistance to oxidation and corrosion make it valuable in aerospace engine applications.

Power Generation: Inconel 601 strip is utilized in power plants for components exposed to high-temperature and corrosive environments. It is employed in boiler tubes, superheater tubes, and other components in coal-fired power plants, where it provides resistance to oxidation, sulfidation, and chloride attack.

Chemical Processing: Inconel 601 strip is employed in various chemical processing applications, including reactors, vessels, and piping systems. Its resistance to a wide range of corrosive chemicals, including acids, alkalis, and chlorides, make it suitable for handling aggressive chemical environments at high temperatures.

Q&A:

Q1: What is the maximum operating temperature of Inconel 601 strip in high temperature environment?

A1: The maximum service temperature of Inconel 601 strip can reach 1,200°C (2,192°F).

Q2: Does Inconel 601 strip have corrosion resistance in sulfide corrosive environment?

A2: Yes, Inconel 601 strip has excellent resistance to sulfide corrosion and can withstand corrosion from sulfur-containing media.

Q3: What are the applications of Inconel 601 strip in the petrochemical industry?

A3: Inconel 601 strip is commonly used in the petrochemical industry to manufacture high temperature and corrosion resistant equipment such as refining equipment, heat exchangers, pipelines and reactors.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China