0

0

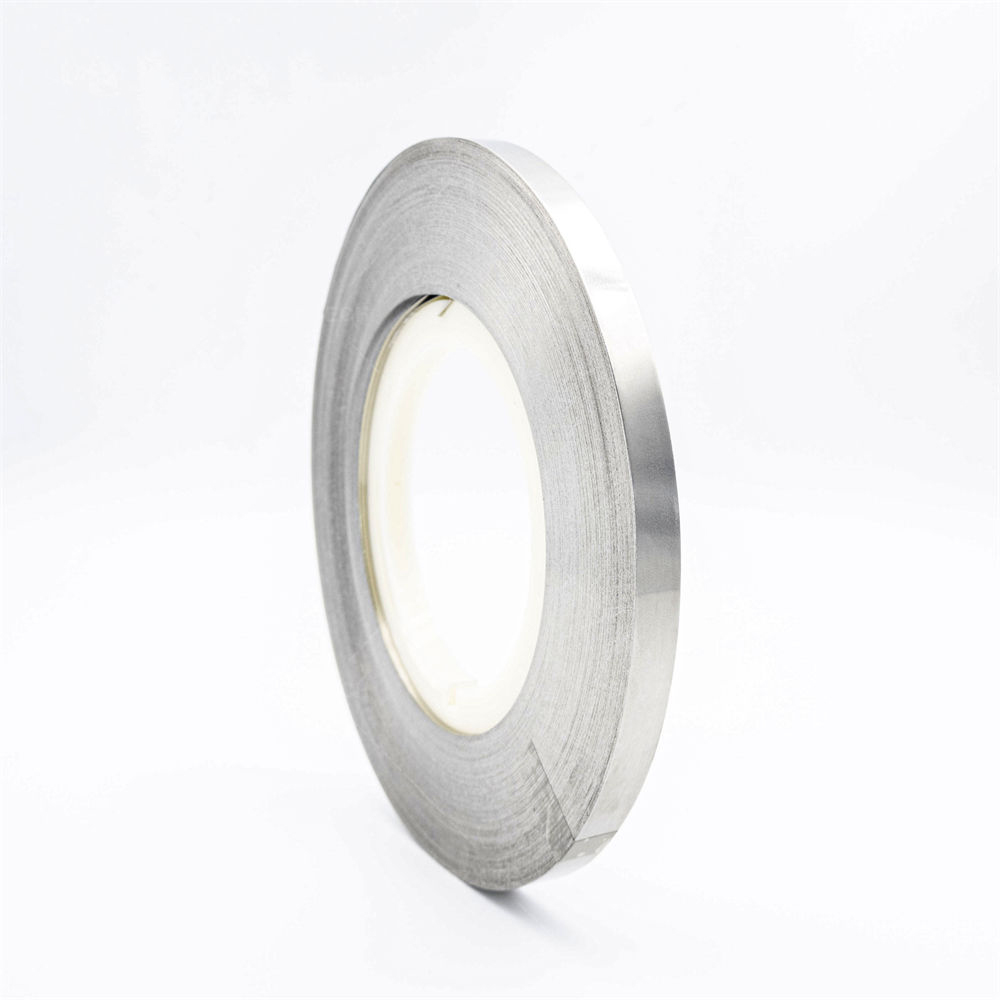

Products Description

Inconel tape is a material widely used in the aerospace industry. It is made of Inconel alloy, which is mainly composed of nickel and chromium and contains other elements such as molybdenum, aluminum and titanium. Inconel tape has excellent high-temperature strength, corrosion resistance and oxidation resistance, making it an ideal material for the aerospace industry.

The aerospace industry places very stringent requirements on materials, especially in the manufacture of critical components such as engines and jet propulsors. These components need to be able to withstand operation in extreme temperatures and harsh environmental conditions while maintaining stable performance. Inconel tape is favored for its excellent high temperature resistance properties. It can maintain good mechanical strength and oxidation resistance in high temperature environments and is not easy to deform or fail. This makes Inconel strip ideal for manufacturing turbine blades, combustor parts, gas nozzles and other high-temperature components.

In addition, Inconel strips also have good corrosion resistance and can resist various corrosive media, including acidic and alkaline environments. This allows it to be used in harsh chemical environments for a long time, reduces the frequency of maintenance and replacement of components, and improves the reliability and life of aerospace systems.

Physical property

Chemical composition: Nickel (≥58%), Chromium (≤23%), Iron (≤1%), Aluminum (≤1%), Silicon (≤0.5%)

Density: 8.11 g/cm³

Melting point: 1,370°C (2,498°F)

Tensile strength: 550 MPa (minimum)

Yield strength: 240 MPa (minimum)

Elongation: 30% (minimum)

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Characteristic:

High Temperature Performance: Inconel tape has excellent high temperature strength and heat resistance, able to maintain its mechanical properties and structural integrity in extreme high temperature environments.

Corrosion resistance: Inconel tape performs well in harsh chemical environments and has excellent corrosion resistance to acidic and alkaline media, oxides and salt water.

Mechanical properties: Inconel tape has excellent mechanical properties, including high strength, good toughness and fatigue resistance, and is able to withstand the high stress and vibration loads found in the aerospace industry.

Dimensional stability: Inconel strips have a low thermal expansion coefficient under temperature changes, can maintain high precision and dimensional stability, and are suitable for the manufacturing of precision parts.

Specific applications:

Engine components: Inconel strips can be used to manufacture key components such as turbine blades, combustion chamber components and nozzles of aero engines to withstand the requirements of high temperature and high pressure environments.

Gas turbines: Inconel tape is widely used in gas turbine components such as blades, blisks and spiral shells to provide reliability and durability in high temperature and corrosive environments.

Aviation structural parts: Inconel strips can be used to manufacture aircraft structural parts, such as support rods, connectors and suspension systems, to provide high strength and corrosion resistance.

Q&A:

Q: What is the thermal stability of Inconel tape in the aerospace industry?

A: Inconel tape has a low thermal expansion coefficient and excellent thermal stability. It can maintain dimensional stability in high temperature environments and is suitable for manufacturing aerospace components that require high precision.

Q: What is the corrosion performance of Inconel strips in the aerospace field?

A: Inconel strips perform well against corrosive media such as acid, alkaline and salt water. They have excellent corrosion resistance and are suitable for aerospace components used in harsh chemical environments.

Q: What are the important applications of Inconel strips in the aerospace industry?

A: Inconel strips are widely used in manufacturing aerospace engine components (such as turbine blades and combustor components), gas turbine components, and aircraft structural parts to meet high temperature, high pressure, and corrosion resistance requirements.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China