0

0

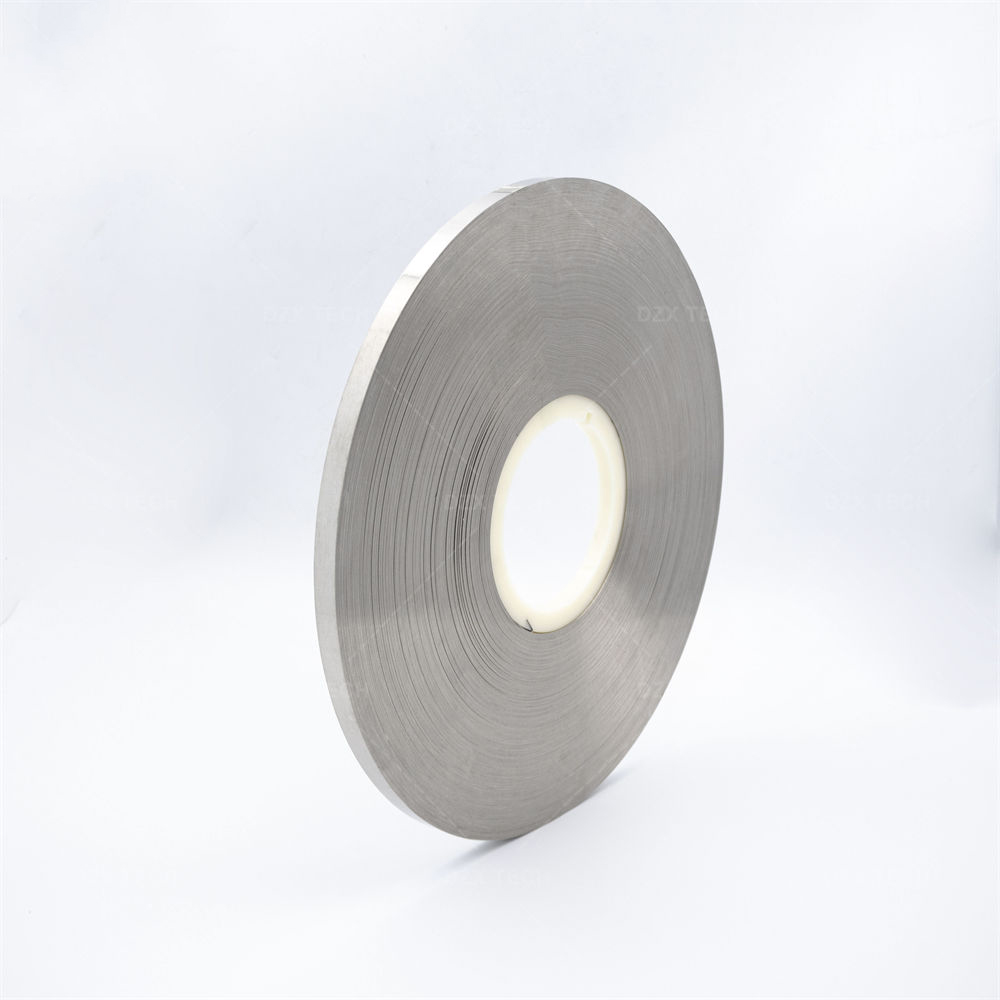

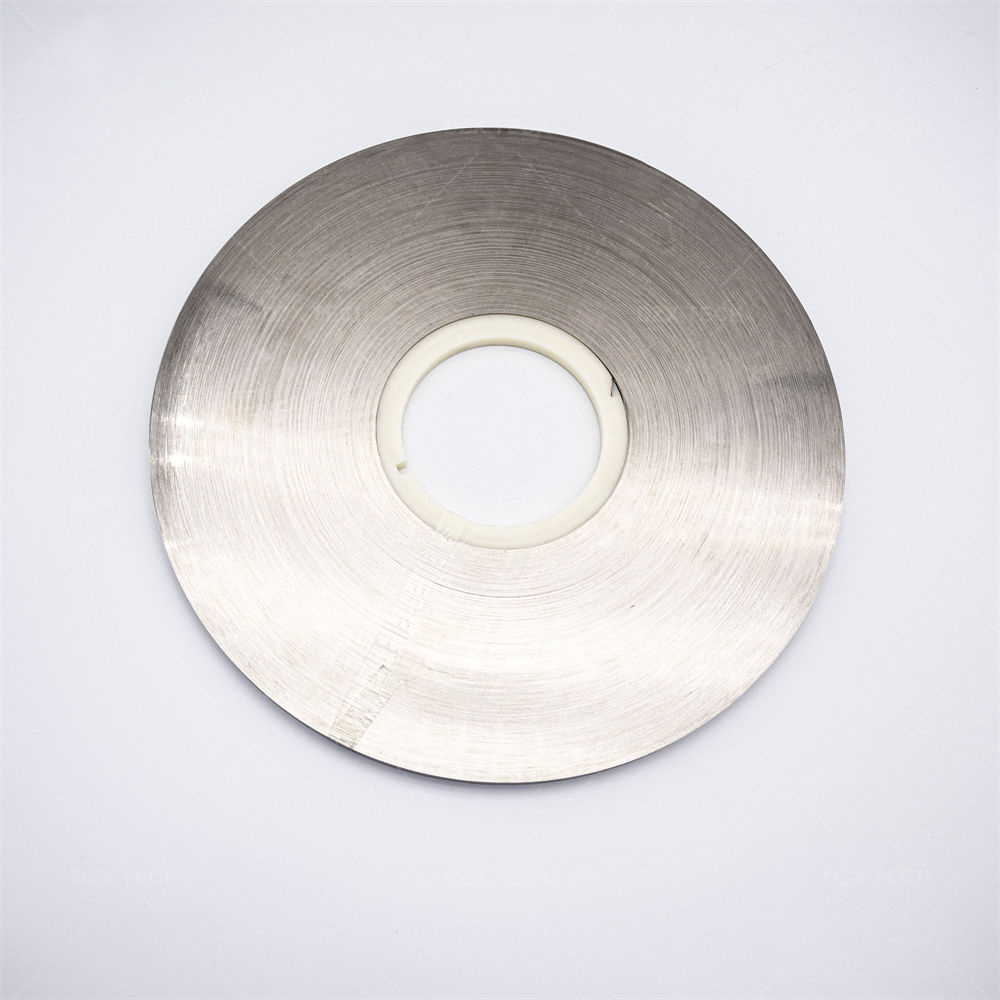

Products Description

Inconel 625 strip is a high performance nickel-based alloy strip with excellent high temperature strength, corrosion resistance and mechanical properties. It uses a special alloy formula that allows it to perform well in extreme thermal environments and corrosive media. Inconel 625 strip is widely used in aerospace, petrochemical, nuclear energy, marine engineering and other fields to manufacture structural parts and components in high temperature, high pressure and corrosive environments. Additionally, Inconel 625 tape has lower magnetic permeability, making it suitable for applications where reduced magnetic interference is required.

Physical property

Chemical composition: nickel (≥58%), chromium (≤23%), iron (≤5%), molybdenum (≤9%), niobium (≤3%), titanium (≤0.4%), aluminum (≤0.4% )

Density: 8.44 g/cm³

Melting point: 1,340°C (2,444°F)

Tensile strength: 760 MPa (minimum)

Yield strength: 345 MPa (minimum)

Elongation: 30% (minimum)

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Characteristic:

High-temperature oxidation resistance: Inconel 625 tape has excellent high-temperature oxidation resistance and can form a dense oxide layer in an oxidizing environment.

Good corrosion resistance: It shows excellent corrosion resistance to corrosive media such as acid, alkaline and chloride.

High strength: Inconel 625 tape has good strength and mechanical properties, maintaining structural stability under high temperatures and extreme environments.

Thermal fatigue resistance: It can withstand the stress and deformation caused by high-temperature thermal cycles and has good thermal fatigue resistance.

Application:

Oil and gas industry: used in marine mining equipment, oil well casing, valves and pipe connections, etc.

Chemical industry: commonly used in reactors, distillation towers and catalyst systems in acidic environments.

Nuclear industry: used in nuclear reactor components, nuclear fuel processing equipment and nuclear waste processing equipment, etc.

Corrosion resistance

Inconel 625 tape has good corrosion resistance, allowing it to perform well in a variety of corrosive environments. The following are its corrosion resistance features:

Acid corrosion resistance: Inconel 625 tape has excellent corrosion resistance to many acidic media, including sulfuric acid, hydrochloric acid, nitric acid and phosphoric acid. It resists corrosion and corrosive damage in acidic environments.

Resistance to alkaline corrosion: Inconel 625 tape shows good corrosion resistance in alkaline media, including alkaline solutions such as sodium hydroxide, potassium hydroxide and ammonia. It resists corrosion and damage caused by alkaline media.

Resistance to chloride corrosion: Inconel 625 strip also has good corrosion resistance to chloride media, including sodium chloride, magnesium chloride and ammonium chloride. This makes it widely applicable in chlorine-containing media such as marine environments and salt water environments.

Resistance to corrosion cracking: Inconel 625 strip has strong resistance to stress corrosion cracking. It can maintain better integrity in high stress and corrosive environments and reduce cracks and fractures caused by corrosion.

Resistant to oxidation and high temperature corrosion: Inconel 625 strip performs well in high temperature oxidation and high temperature corrosion environments. It can form a dense oxide layer to prevent further oxidation and corrosion, and is suitable for oxidizing and corrosive environments in high-temperature applications.

Q&A:

Q1: Compared with Inconel 601 strip, what are the differences in high-temperature corrosive environments?

A1: Inconel 625 strip performs well in corrosive environments such as acid, alkaline and chloride, while Inconel 601 strip has more advantages in high temperature oxidation and sulfide corrosion.

Q2: What are the applications of Inconel 625 strip in the oil and gas industry?

A2: Inconel 625 strip is widely used in marine mining equipment, oil well casing, valves and pipeline connections, etc., providing excellent corrosion resistance in harsh oil and gas environments.

Q3: What are the application fields of Inconel 625 strip in the nuclear industry?

A3: Inconel 625 strip is used in the nuclear industry to manufacture nuclear reactor components, nuclear fuel processing equipment, and nuclear waste processing equipment. It is favored for its corrosion resistance and high temperature stability.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China