0

0

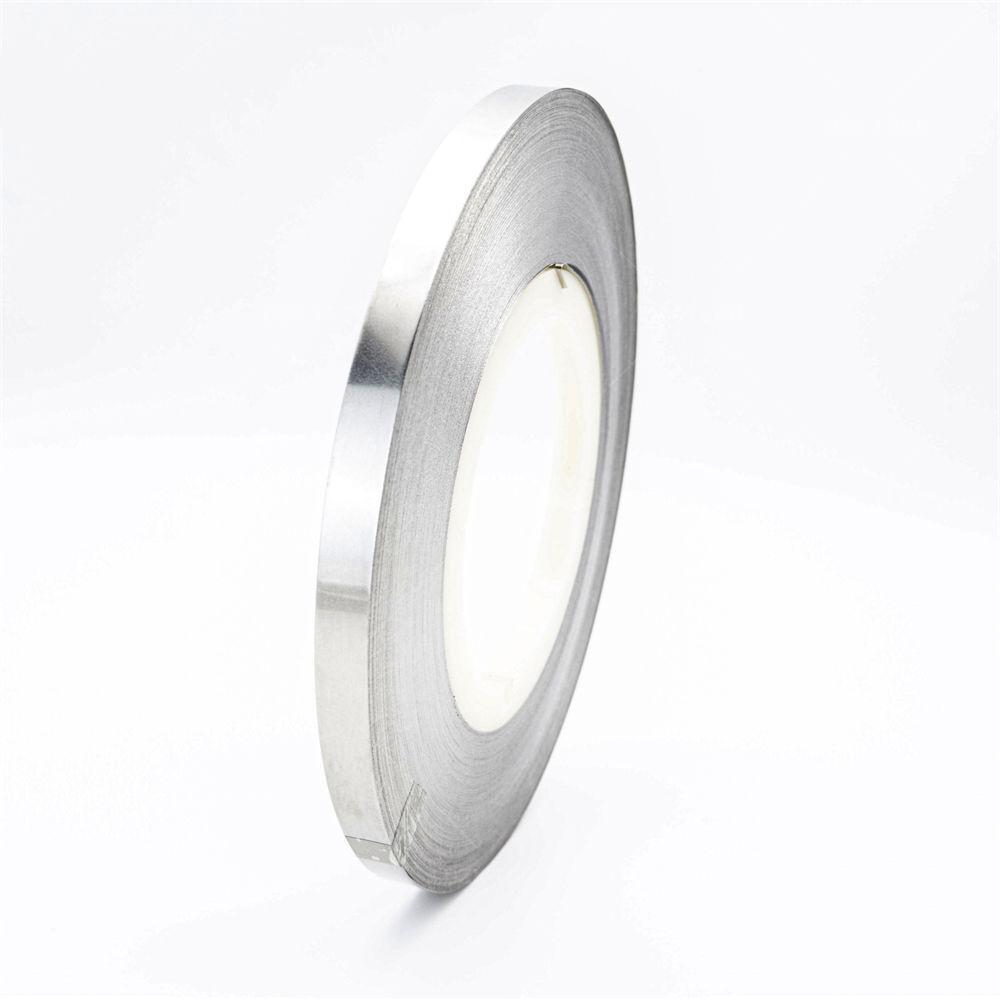

Products Description

Inconel strips have a wide range of applications in heat treatment and high temperature processing. Due to its excellent high-temperature strength, corrosion resistance and oxidation resistance, Inconel tape is widely used in a variety of applications that require processing and handling in high-temperature environments.

In heat treatment, Inconel strips are often used to manufacture heat treatment equipment and tools, such as furnaces, grates, heating elements and stoves. These equipment need to be able to withstand extremely high temperatures while maintaining structural stability and mechanical strength, and Inconel tape is ideal for these properties.

During high-temperature processing, Inconel strips are also widely used in various industrial fields, such as aerospace, energy and automobile manufacturing. It is often used to manufacture tools and molds at high temperatures, such as high-temperature stoves, hot pressing molds and extrusion molds. Because Inconel strip has excellent high-temperature strength and corrosion resistance, it can maintain stability under extreme processing conditions and provide reliable processing results.

In summary, Inconel strip plays an important role in the fields of heat treatment and high-temperature processing due to its excellent high-temperature strength, corrosion resistance and oxidation resistance. Its application in heat treatment equipment, tool manufacturing and high-temperature pipelines provides reliable solutions for high-temperature processing and processing in various industries.

Physical property

Chemical composition: Nickel (≥58%), Chromium (≤23%), Iron (≤1%), Aluminum (≤1%), Silicon (≤0.5%)

Density: 8.11 g/cm³

Melting point: 1,370°C (2,498°F)

Tensile strength: 550 MPa (minimum)

Yield strength: 240 MPa (minimum)

Elongation: 30% (minimum)

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

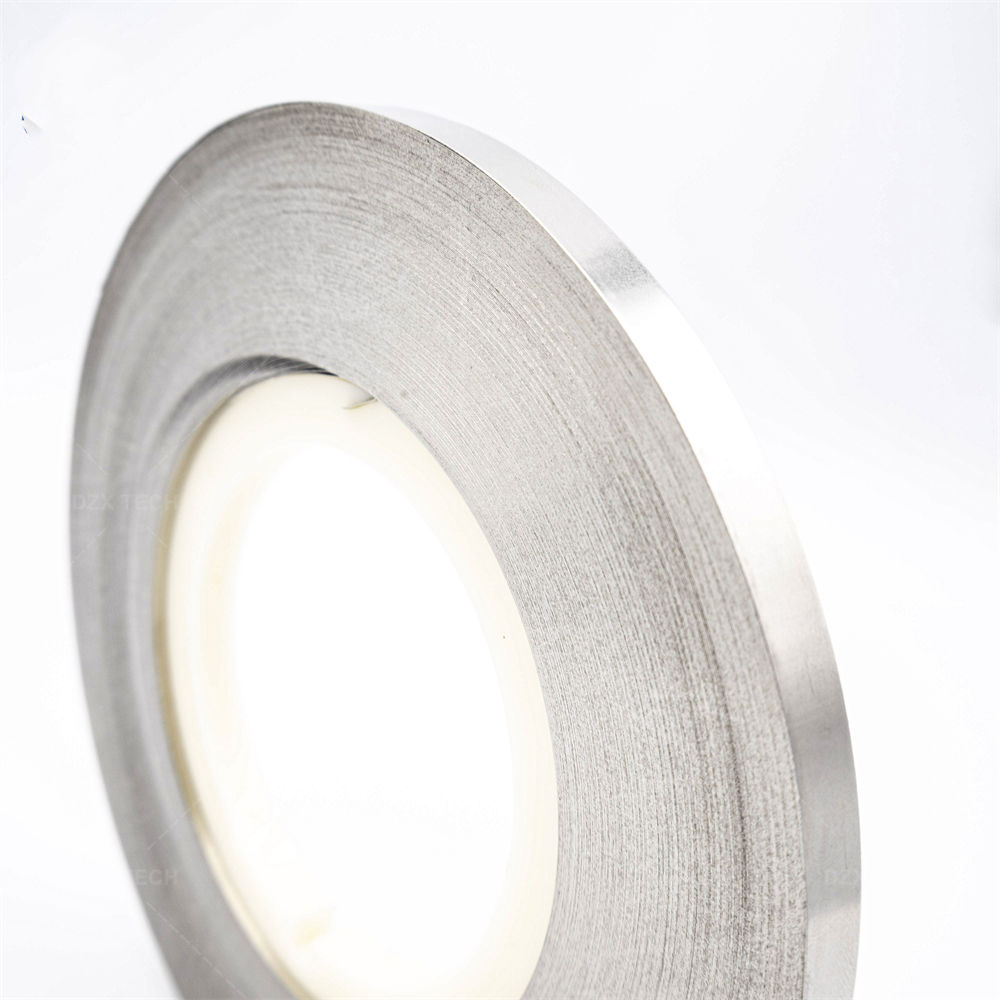

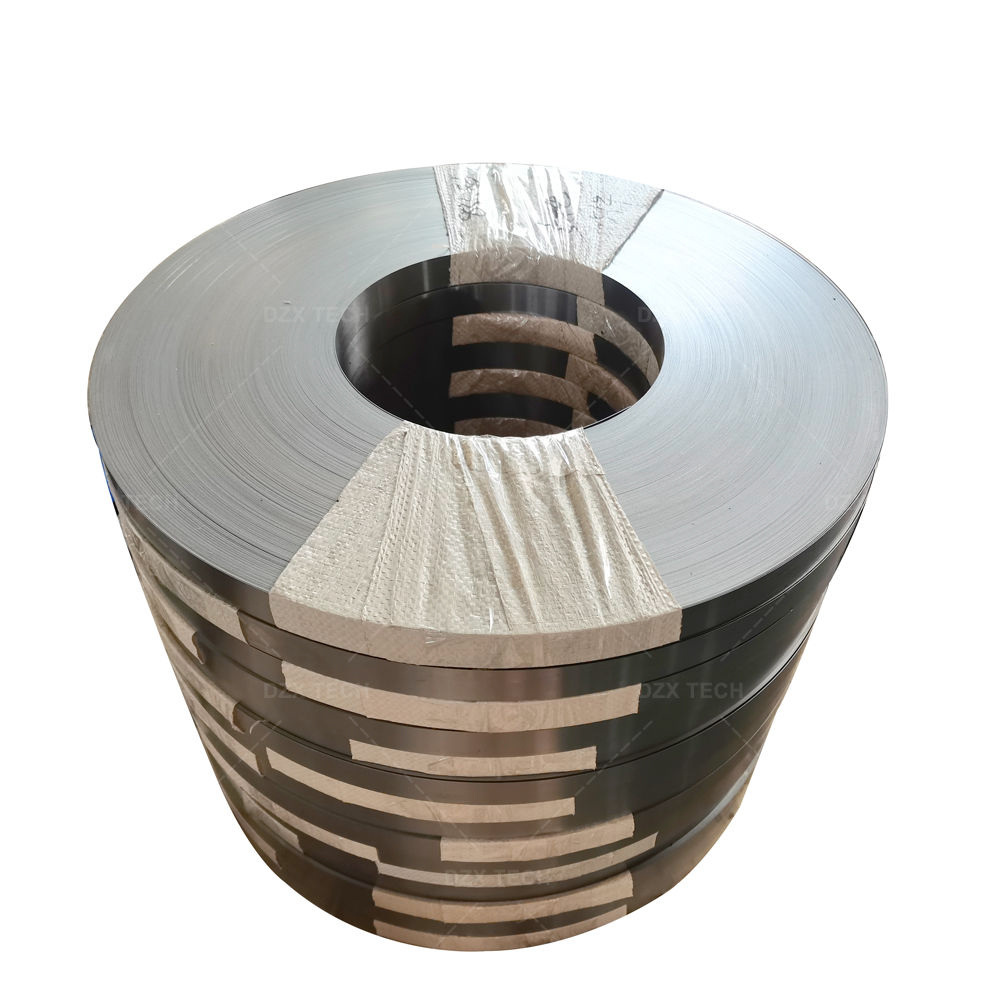

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Characteristic:

High temperature stability: Inconel strips can maintain good strength and stability under high temperature conditions, have excellent high temperature deformation resistance, and are suitable for high temperature processing and heat treatment applications.

Oxidation resistance: Inconel tape has excellent antioxidant properties and can resist oxidation in high temperature environments and extend the service life of the material.

Corrosion resistance: Inconel strips have good corrosion resistance to many corrosive media, can withstand the erosion of acidic and alkaline environments, and are suitable for use in corrosive working environments.

Specific applications:

High-temperature processing: Inconel strips can be used in high-temperature processing fields, such as high-temperature forging, hot extrusion, and high-temperature quenching, to manufacture components and tools in high-temperature working environments.

Heat treatment equipment: Inconel strips are widely used in heat treatment equipment, such as furnace tubes, heating elements and grates, etc., to provide stability and corrosion resistance during high-temperature heating and heat treatment processes.

High-temperature gas turbines: Inconel strips can be used to manufacture blades and rotors in high-temperature gas turbines, which are suitable for aviation, energy and power generation and other fields, providing reliability under high temperature and high strength requirements.

Q&A:

Q: What are the advantages of Inconel strips in high temperature processing?

A: Inconel strip has excellent high-temperature stability and deformation resistance. It is suitable for high-temperature processing processes, such as high-temperature forging and hot extrusion, and can provide stable material properties and reliability in high-temperature working environments.

Q: What are the specific applications of Inconel strips in heat treatment equipment?

A: Inconel strips can be used to manufacture furnace tubes, heating elements, grates and other components of heat treatment equipment, providing stability and corrosion resistance during high-temperature heating and heat treatment.

Q: In what areas are Inconel strips used to manufacture high-temperature gas turbines?

A: Inconel strips can be used to manufacture blades and rotors in high-temperature gas turbines. They are widely used in aviation, energy, power generation and other fields, providing reliability under high temperature and high strength requirements.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China