0

0

Products Description

Inconel tape has a wide range of applications in the nuclear industry. The nuclear industry involves areas such as nuclear power generation, nuclear fuel cycle and nuclear waste processing, and has very strict requirements for materials. Inconel tape plays an important role in the nuclear industry due to its excellent high-temperature strength, corrosion resistance and radiation resistance. It is widely used in key areas such as nuclear reactors, nuclear fuel cycles and nuclear waste processing to ensure the safety, reliability and stable operation of the nuclear industry.

Physical property

Chemical composition: Nickel (≥58%), Chromium (≤23%), Iron (≤1%), Aluminum (≤1%), Silicon (≤0.5%)

Density: 8.11 g/cm³

Melting point: 1,370°C (2,498°F)

Tensile strength: 550 MPa (minimum)

Yield strength: 240 MPa (minimum)

Elongation: 30% (minimum)

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

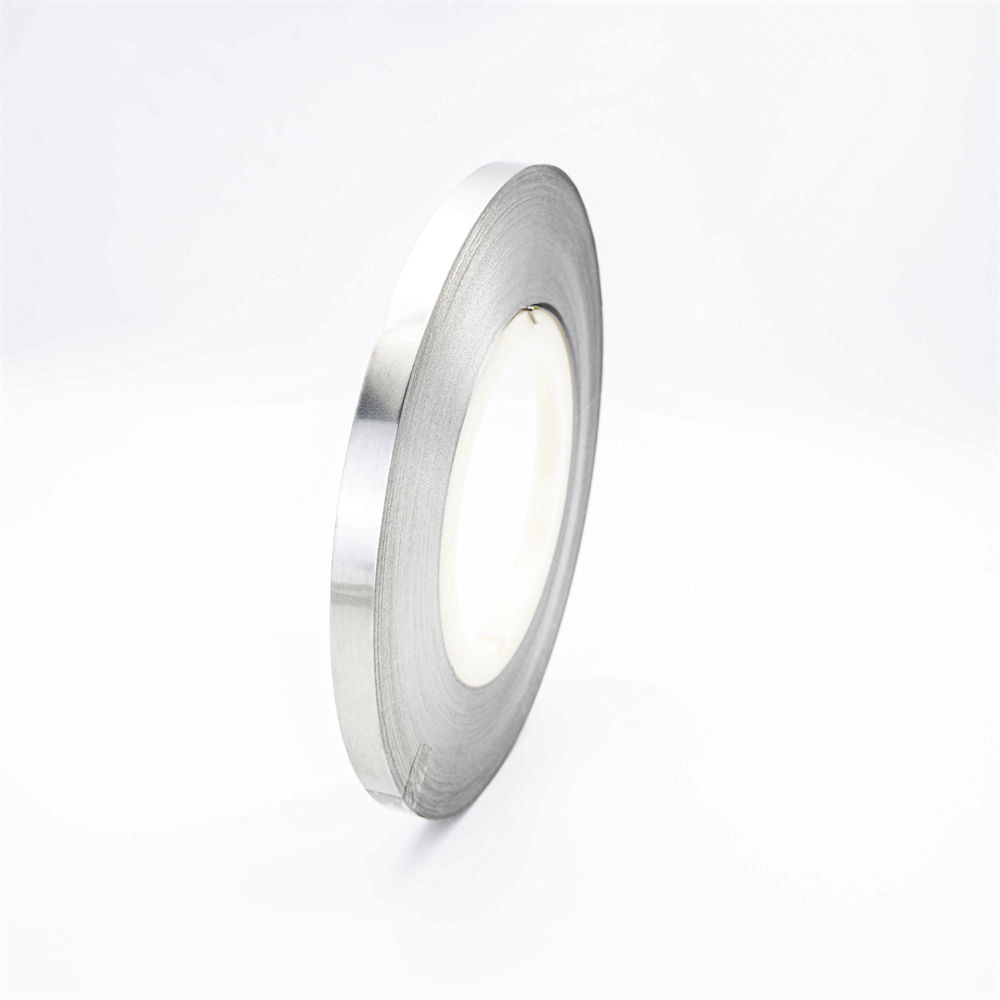

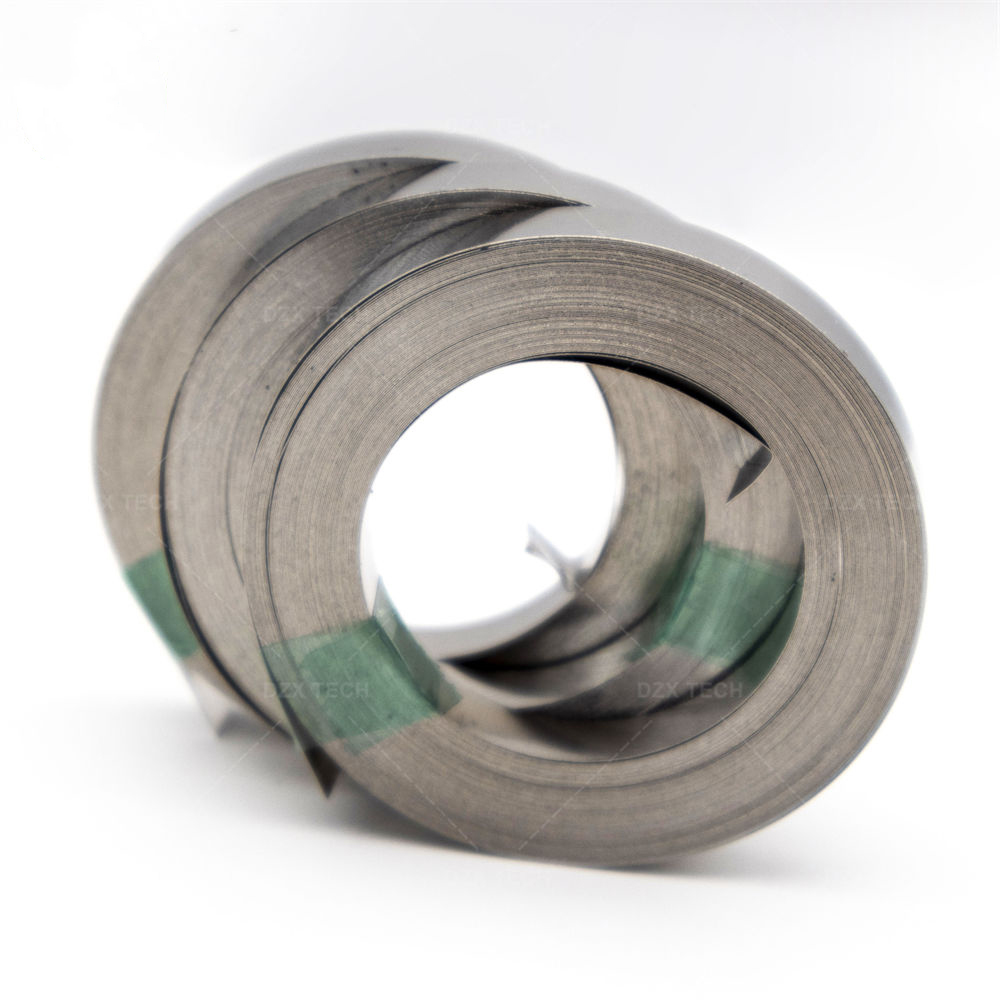

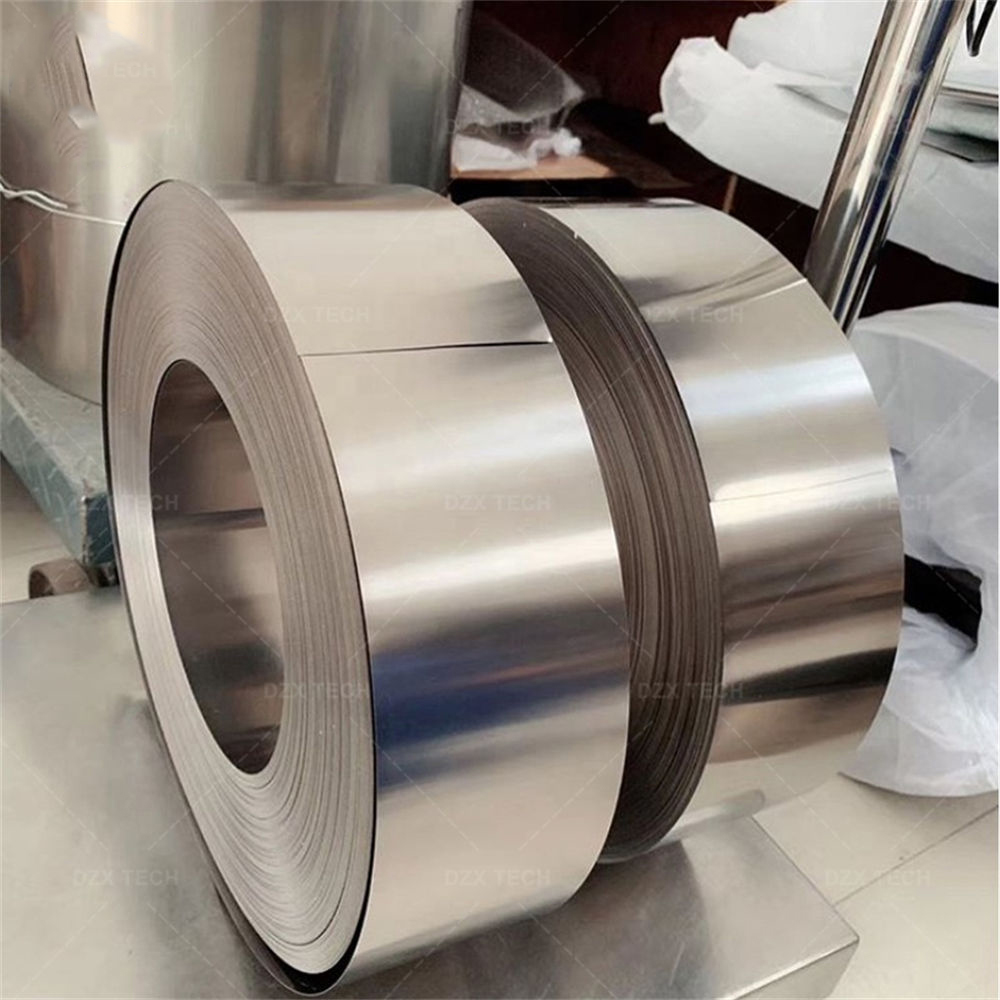

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Characteristic:

Radiation Resistance: Inconel tape has excellent radiation resistance and is able to withstand long-term exposure to radiation environments in the nuclear industry without losing strength and corrosion resistance.

High temperature performance: Inconel strips can maintain good strength and stability under high temperature conditions and are suitable for high temperature components and fuel elements in nuclear reactors.

Corrosion resistance: Inconel strips have excellent corrosion resistance to corrosive media commonly found in the nuclear industry and can maintain stability in acidic and alkaline environments.

Specific applications:

Nuclear reactor components: Inconel strips can be used to manufacture components in nuclear reactors, such as fuel elements, fuel cladding, and control rods, to provide durability and reliability in high-temperature, highly corrosive environments.

Nuclear fuel processing: Inconel strips are widely used in nuclear fuel processing equipment, such as concentrators, extractors, and solvent extraction towers, to handle high temperatures and corrosive media.

Nuclear waste treatment: Inconel tape can be used in nuclear waste treatment equipment, such as storage containers, sealing devices and processing devices, to ensure safety and reliability in radiation environments.

Q&A:

Q: What is the radiation resistance of Inconel tape in the nuclear industry?

A: Inconel tape has excellent radiation resistance and can be exposed to long-term radiation environments in the nuclear industry without losing strength and corrosion resistance. It is suitable for nuclear reactors and nuclear waste treatment and other fields.

Q: What are the applications of Inconel strips in nuclear reactors?

A: Inconel strips can be used to manufacture components such as fuel elements, fuel cladding, and control rods in nuclear reactors to provide durability and reliability in high-temperature, highly corrosive environments.

Q: What is the specific role of Inconel tape in nuclear waste disposal?

A: Inconel strips can be used to manufacture nuclear waste treatment equipment, such as storage containers, sealing devices and processing devices, to ensure safety and reliability in radiation environments and promote the safe handling and storage of nuclear waste.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China