0

0

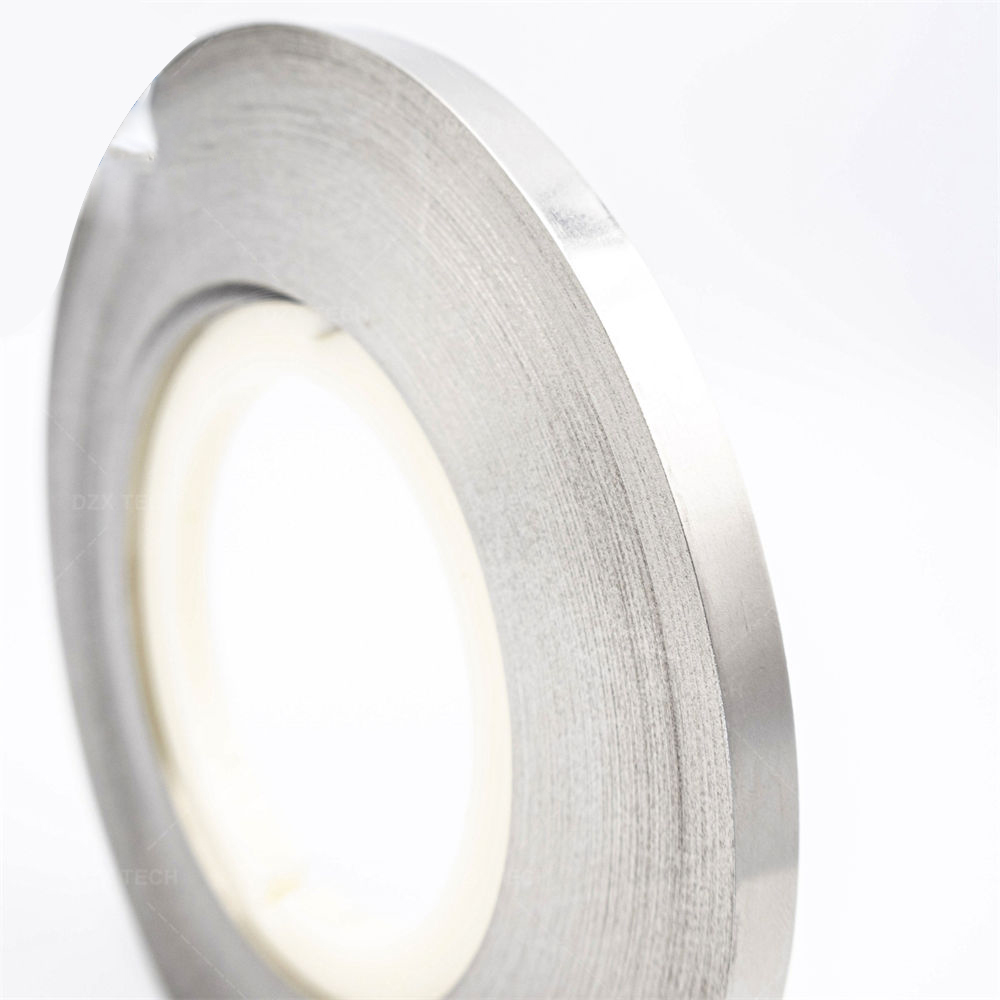

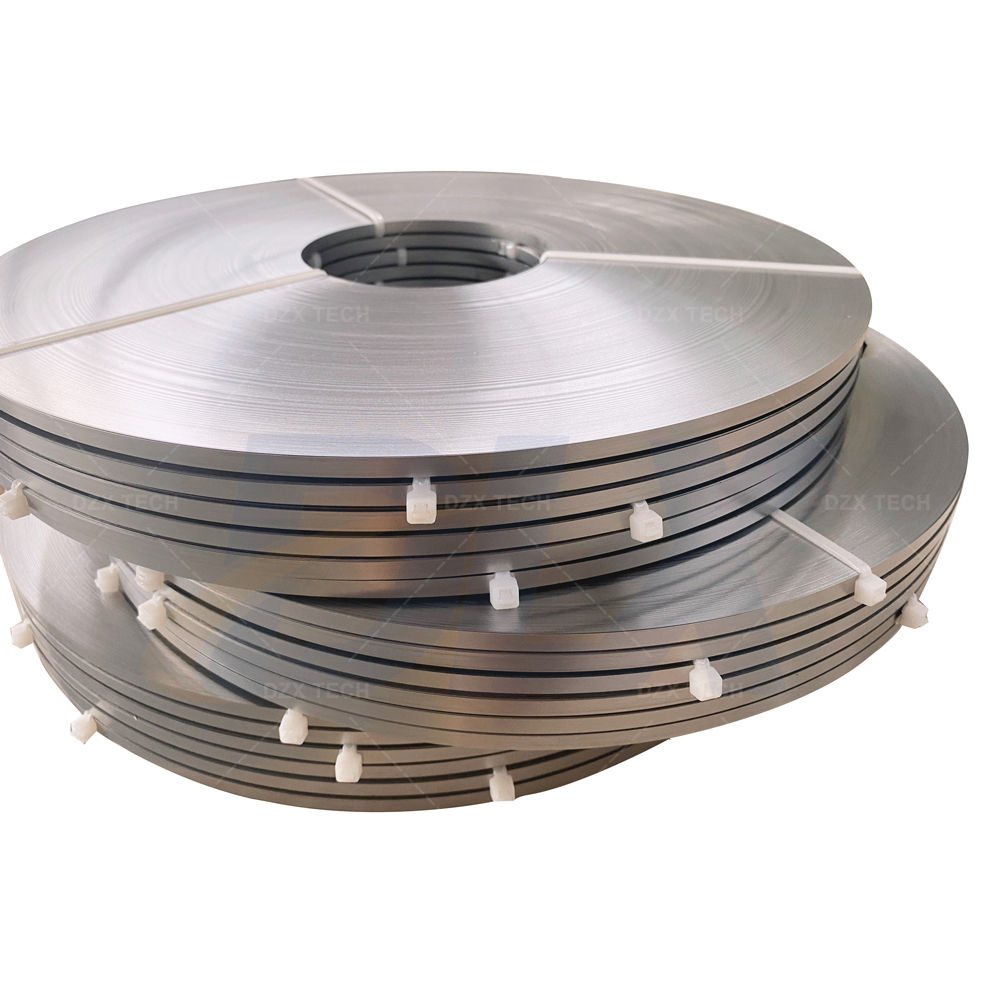

Products Description

Inconel 600 strip is a high-temperature alloy strip mainly composed of elements such as nickel and chromium. It has excellent high temperature oxidation resistance, corrosion resistance and high strength properties. Inconel 600 tape performs well in extreme high temperature environments and is resistant to oxidation and sulfide corrosion. It is widely used in aerospace, chemical industry, petroleum, nuclear industry and heat treatment and other fields. Inconel 600 strip is often used in the petrochemical industry to manufacture equipment such as distillation columns, heat exchangers and storage tanks. In addition, it is used in the heat treatment industry to manufacture components such as furnace heating elements and furnace door seals. Inconel 600 strip has become an ideal material choice for extreme working conditions due to its stable high temperature performance and good corrosion resistance.

Physical property

Chemical composition: Nickel (≥72%), Chromium (≤15%), Iron (≤6%), Carbon (≤0.15%), Silicon (≤0.5%), Sulfur (≤0.015%)

Density: 8.47 g/cm³

Melting point: 1,371°C (2,500°F)

Tensile strength: 550 MPa (minimum)

Yield strength: 240 MPa (minimum)

Elongation: 30% (minimum)

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Feature

High temperature oxidation resistance: Inconel 600 tape can form a dense oxide layer in high temperature environments to protect the substrate from oxidative corrosion.

Good corrosion resistance: It has high corrosion resistance against corrosive media such as acid, alkaline and chloride.

Excellent mechanical properties: Inconel 600 tape has high strength and hardness, allowing it to maintain stability under high temperature and high stress conditions.

Good processing performance: It can be processed into various shapes and sizes through cold rolling, hot rolling and welding.

Application

Petrochemical industry: equipment such as distillation towers, heat exchangers, storage tanks, pipes and valves.

Heat treatment industry: components such as furnace heating elements, furnace door seals and heat shields.

Aerospace: high-temperature parts such as engine components, turbine blades and combustion chamber components.

Nuclear Industry: Fuel elements and cooling system components in nuclear reactors.

Q&A

Q1: Is Inconel 600 strip suitable for high temperature oxidation environment?

A1: Yes, Inconel 600 tape has excellent high-temperature oxidation resistance and is able to maintain its structural integrity in high-temperature oxidizing environments.

Q2: Can Inconel 600 strip resist corrosion from acidic media?

A2: Yes, Inconel 600 strip has good corrosion resistance to acidic media and can resist the erosion of acidic media.

Q3: In what fields is Inconel 600 strip widely used?

A3: Inconel 600 strip is widely used in petrochemical, heat treatment, aerospace and nuclear industries to manufacture various high temperature and corrosion resistant equipment and parts.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China