0

0

Products Description

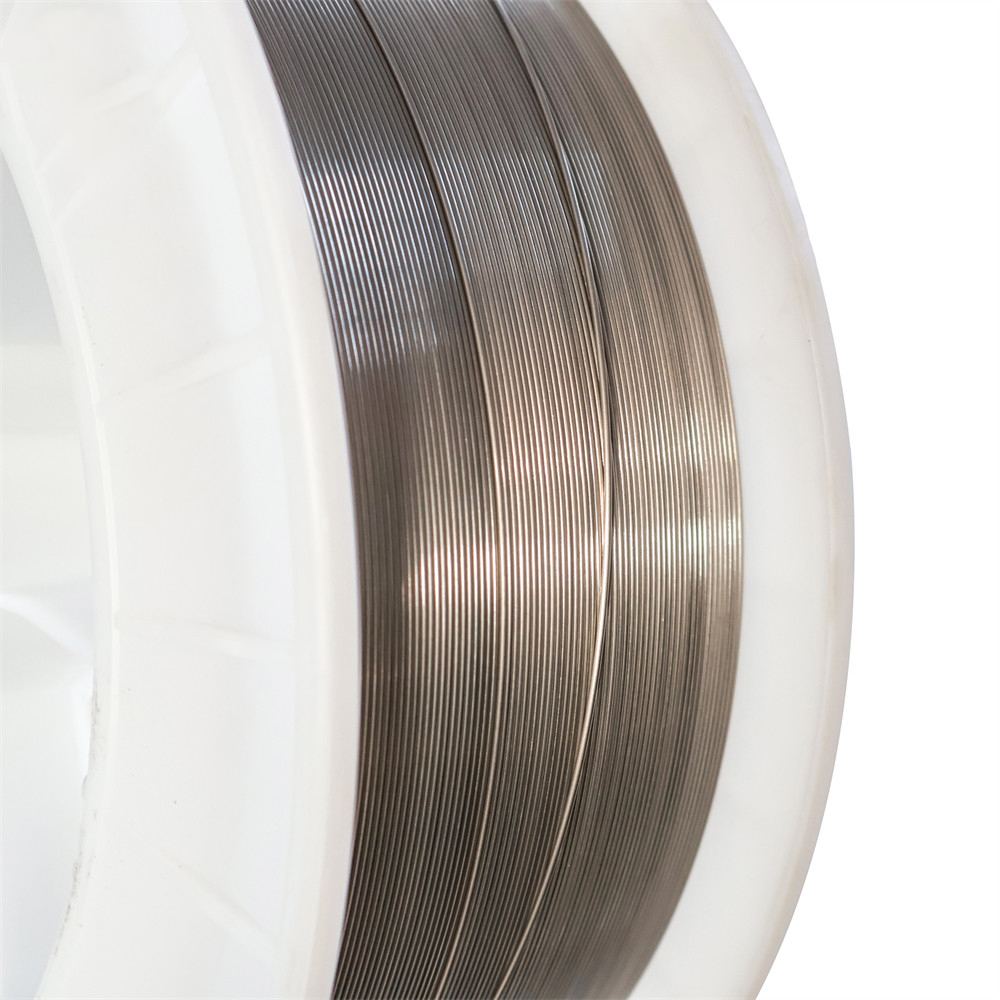

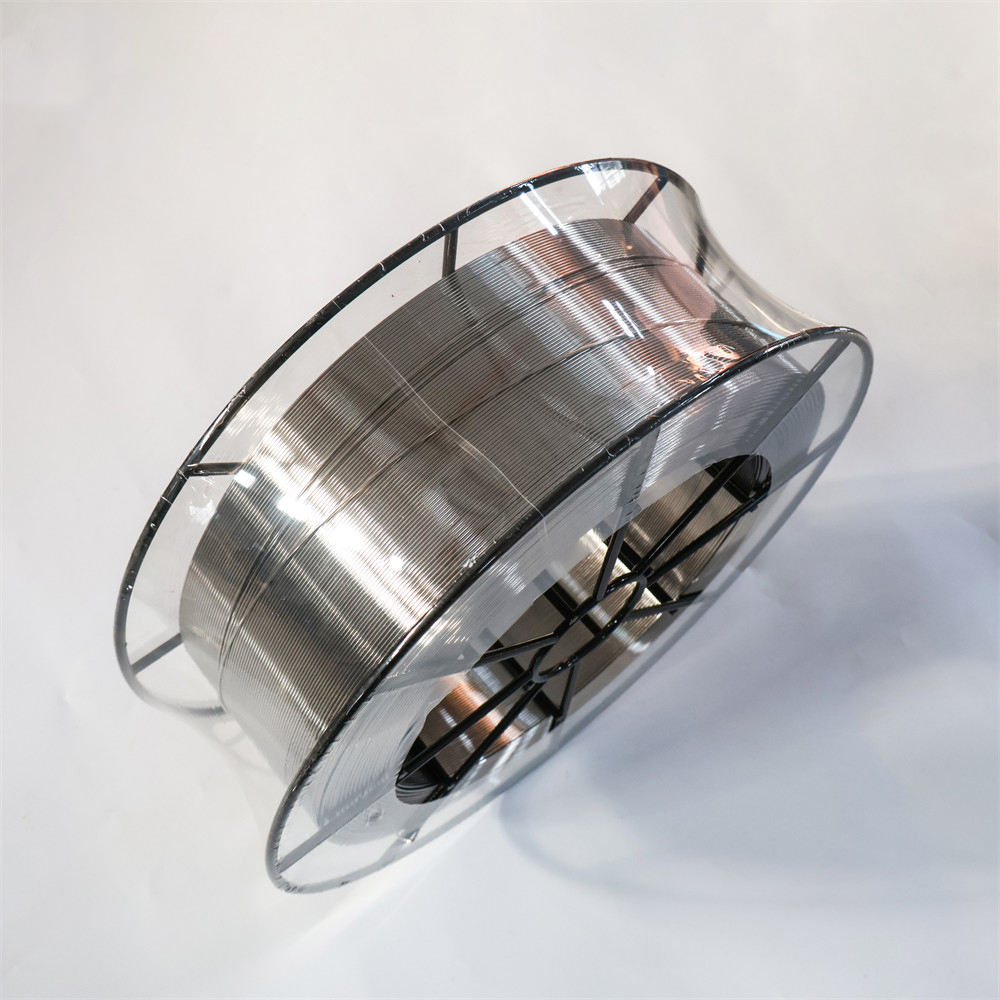

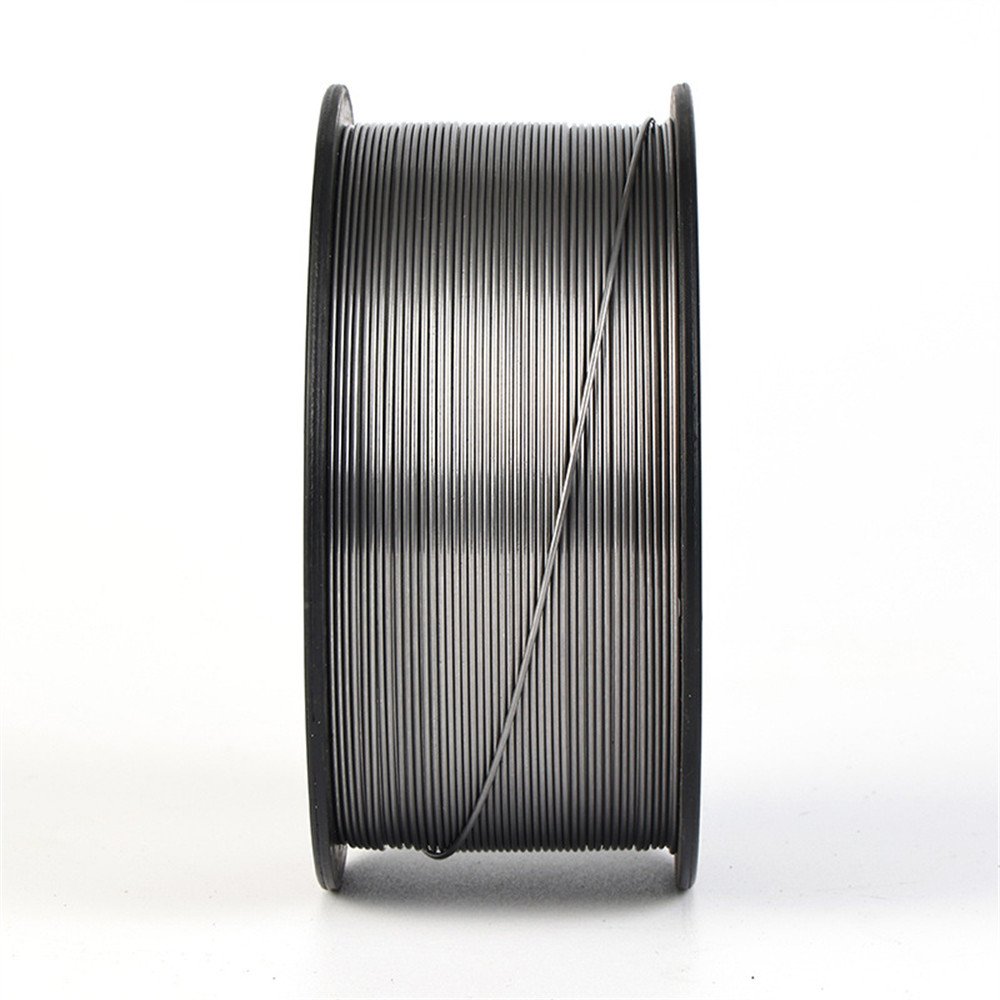

45CT thermal spray wire is a commonly used spray material, usually used for high-temperature, wear-resistant, and corrosion-resistant coating applications. The main components of the material include chromium (Cr), molybdenum (Mo) and titanium (Ti). The higher content of chromium and molybdenum gives it excellent corrosion resistance and high temperature stability. The diameter of 45CT thermal spray wire is usually between 0.8mm and 3.2mm, and the tensile strength can reach 400MPa to 600MPa, ensuring the mechanical properties and strength of the coating. Its melting point is approximately 1350°C (2460°F) and shows good stability in high temperature environments.

In addition to excellent high temperature resistance and corrosion resistance, 45CT thermal spray wire also has good wear resistance and is suitable for occasions that require wear-resistant coating protection. Its coating hardness is usually between 250HV and 350HV, and it has good wear resistance and scratch resistance.

45CT is a high-chromium nickel-based arc spray wire material. This material is mainly used for high-temperature corrosion protection of the four tubes of boilers in thermal power plants, including water-cooled wall tubes, superheater tubes, reheater tubes and economizer tubes. Due to its excellent high-temperature resistance to oxidation, sulfide corrosion and dust erosion, 45CT plays an important role in increasing the service life of the four boiler tubes.

Although the corrosion resistance of 45CT thermal spray wire is slightly inferior to some nickel-based alloys such as Inconel 625, it performs well in wear resistance and high temperature stability, so it has extensive applications in some engineering fields that require higher wear resistance. Applications such as turbomachinery, automotive components, hydraulic cylinders, etc. Its excellent performance makes 45CT thermal spray wire one of the important choices in the field of coating protection.

Thermal spray wire series: Inconel 625, 45CT, Ni95Al5, Monel 400, Monel K500, Hastelloy C276, Cr20Ni80, pure zinc wire

Specification

Item | Inconel 625 | Ni95Al5 | 45CT | Monel 400 | Monel K500 | HC-276 | Cr20Ni80 |

C | ≤0.05 | ≤0.02 | 0.01-0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 |

Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.06 |

P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 |

S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 |

Cr | 21.5-23 | ≤0.2 | 42-46 | -- | -- | 14.5-16 | 20-23 |

Ni | rest | rest | rest | 65-67 | rest | rest | rest |

Cu | -- | -- | -- | rest | 27-33 | -- | -- |

Mo | 8.5-10 | -- | -- | -- | -- | 15-17 | -- |

Ti | ≤0.4 | 0.4-1 | 0.3-1 | 2.0-3 | 0.35-0.85 | -- | -- |

Al | ≤0.4 | 4-5 | -- | ≤0.5 | 2.3-3.15 | -- | -- |

Fe | ≤1.0 | -- | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | -- |

Nb | 3.5-4.15 | -- | -- | -- | -- | -- | ≤1.0 |

| Co | -- | -- | -- | -- | -- | -- | -- |

V | -- | -- | -- | -- | -- | ≤0.35 | -- |

W | -- | -- | -- | -- | -- | 3.0-4.5 | -- |

Impurities | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

For more details, pls directly contact us.

Main features

High chromium content: The main components of 45CT include 45% chromium (Cr), less than 4% titanium (Ti), and the balance nickel (Ni). This combination of ingredients gives the material excellent high-temperature oxidation resistance.

Formation of dense oxide film at high temperature: At high temperature, the surface of the coating prepared by 45CT spray wire can form a high-density Cr2O3 oxide film, which significantly improves the ability to resist sulfide corrosion.

High temperature corrosion resistance: 45CT coating can resist the erosion of corrosive gases generated during boiler operation, such as sulfur and vanadium, at temperatures close to 980°C.

Long-term stability: After the coating is used for 24 months, the thickness basically does not change, and the average erosion rate is less than 0.0127mm/year, which helps extend the service life of the four-tube to more than 7 years.

Thermal expansion coefficient matching: The coating has a similar thermal expansion coefficient to carbon steel, which helps prevent the coating from peeling off.

Self-bonding effect: A self-bonding effect can occur between the coating and the substrate, which enhances the adhesion of the coating.

Low porosity: The porosity of the coating is less than 1% and there are no penetrating holes, providing good protective performance.

Application areas

45CT thermal spray wire is mainly used in:

Thermal power plant: high temperature anti-corrosion and wear-resistant coating for boiler four tubes.

Waste incinerator: In working conditions with high protection requirements, such as waste incinerators and black liquor boilers, 45CT is also the preferred spray material.

Conclusion

45CT thermal spray wire plays an important role in industrial applications, especially in the protection of the four tubes of boilers in thermal power plants, with its excellent high-temperature protection properties. With the continuous advancement of thermal spray technology, the application range of 45CT thermal spray wire is expected to be further expanded.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China