0

0

Products Description

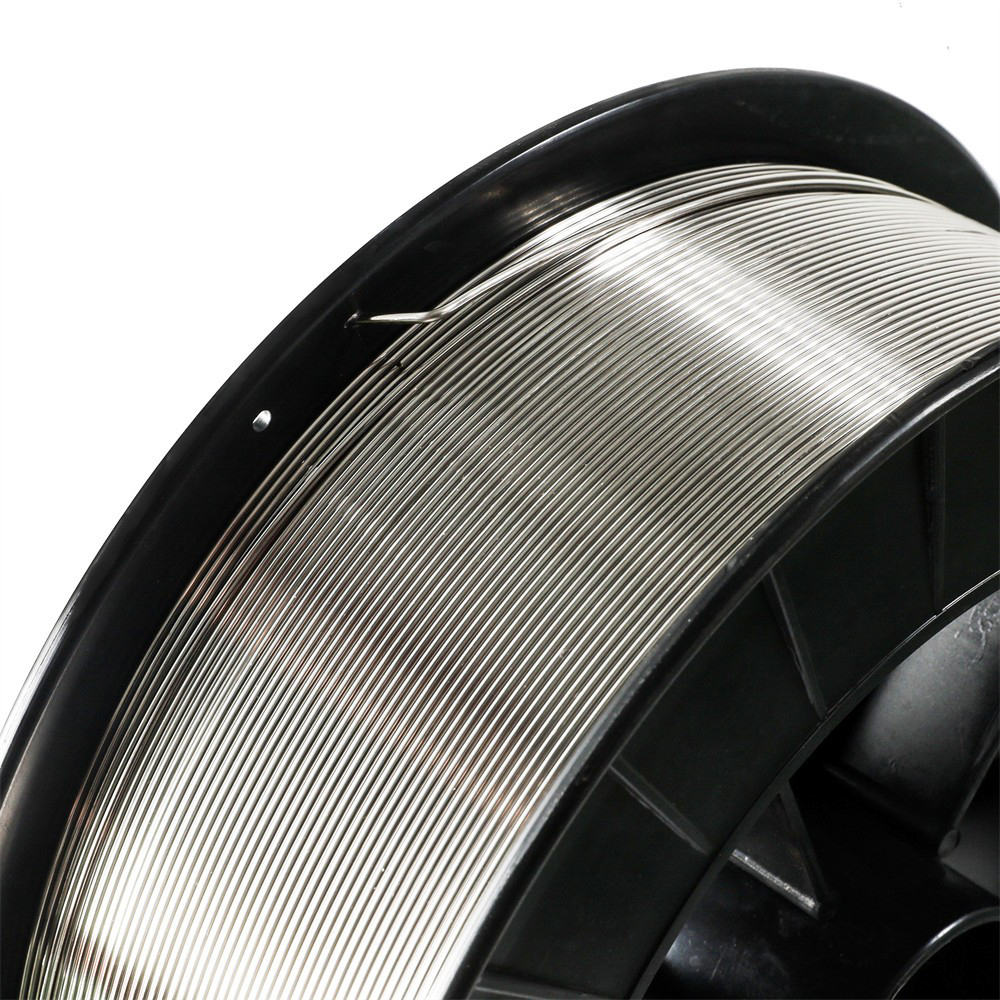

Monel K500 thermal spray wire is a commonly used coating material based on Monel alloy. Compared with Monel 400, alloy elements such as aluminum (Al) and titanium (Ti) are added to the chemical composition. The main components of this alloy are nickel and copper, with the nickel content exceeding 63% and the copper content ranging from 28% to 34%. A certain proportion of aluminum and titanium are also added to increase its strength and hardness.

The diameter of Monel K500 thermal spray wire is usually between 0.8mm and 3.2mm, and it has high tensile strength, which can reach more than 800MPa. It has a melting point of approximately 1300°C (2375°F) and remains stable in high temperature environments. In addition to excellent oxidation resistance and corrosion resistance, Monel K500 also has good weldability and processability.

Due to its excellent performance characteristics, Monel K500 thermal spray wire is widely used in marine engineering, chemical industry, aerospace, energy and other fields, such as seawater treatment equipment, ship parts, chemical valves, etc. Under the demand for coating protection that requires higher strength and hardness, Monel K500 has become one of the important choices in engineering design.

Thermal spray wire series: Inconel 625, 45CT, Ni95Al5, Monel 400, Monel K500, Hastelloy C276, Cr20Ni80, pure zinc wire

Specification

Item | Inconel 625 | Ni95Al5 | 45CT | Monel 400 | Monel K500 | HC-276 | Cr20Ni80 |

C | ≤0.05 | ≤0.02 | 0.01-0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 |

Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.06 |

P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 |

S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 |

Cr | 21.5-23 | ≤0.2 | 42-46 | -- | -- | 14.5-16 | 20-23 |

Ni | rest | rest | rest | 65-67 | rest | rest | rest |

Cu | -- | -- | -- | rest | 27-33 | -- | -- |

Mo | 8.5-10 | -- | -- | -- | -- | 15-17 | -- |

Ti | ≤0.4 | 0.4-1 | 0.3-1 | 2.0-3 | 0.35-0.85 | -- | -- |

Al | ≤0.4 | 4-5 | -- | ≤0.5 | 2.3-3.15 | -- | -- |

Fe | ≤1.0 | -- | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | -- |

Nb | 3.5-4.15 | -- | -- | -- | -- | -- | ≤1.0 |

| Co | -- | -- | -- | -- | -- | -- | -- |

V | -- | -- | -- | -- | -- | ≤0.35 | -- |

W | -- | -- | -- | -- | -- | 3.0-4.5 | -- |

Impurities | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

For more details, pls directly contact us.

Feature

Higher strength and hardness: The addition of alloy elements such as aluminum and titanium gives Monel K500 higher strength and hardness than Monel 400. This makes it excellent in applications that require higher tensile strength, such as in high-load, high-stress working environments or where resistance to impact and wear is required.

Better corrosion resistance: Monel K500 also inherits the excellent corrosion resistance of Monel alloy, especially in seawater, salt water and chemical media, with outstanding performance. This makes it a common choice in the marine engineering and chemical industries for protecting equipment from the effects of corrosion.

Excellent processability and weldability: Monel K500 has good processability and weldability, which means that it can be processed and welded relatively easily to meet the coating needs of complex structures. This property makes it useful in applications requiring customized coating solutions.

High temperature stability: Like Monel 400, Monel K500 can also maintain stability in high temperature environments, which makes it suitable for scenarios that require working in high temperature environments, such as engine parts in the aerospace field.

Application

Marine engineering: Used in seawater treatment equipment, marine platform structures, marine guidance systems, etc. to resist seawater corrosion and high loads in marine environments.

Chemical industry: Used for coating protection of chemical valves, pipelines, reactors and other equipment to cope with the erosion of highly corrosive chemical media.

Aerospace: Used as protective coating for aircraft engine parts, rocket thrusters and other parts that need to work in high temperature, high pressure and high speed environments.

Energy field: Used for coating protection of oil drilling equipment, nuclear power equipment, etc. in extreme working environments to ensure long-term stable operation of the equipment.

Q&A

Q: What are the main differences between Monel 400 and Monel K500?

Answer: The main difference is the alloy composition. Monel 400 is mainly composed of nickel and copper, while Monel K500 adds alloy elements such as aluminum and titanium. These added elements increase the strength and stiffness of Monel K500, making it perform better in certain applications.

Q: What is the diameter range of thermal spray filaments for Monel 400 and Monel K500?

Answer: Generally, the thermal spray wire diameter of Monel 400 and Monel K500 is between 0.8mm and 3.2mm. This range can meet the needs of most coating applications while also allowing selection based on specific project requirements.

Q: What specific engineering fields is Monel K500 thermal spray wire suitable for?

Answer: Monel K500 thermal spray wire is suitable for many engineering fields, especially in scenarios that require higher strength, better corrosion resistance and high temperature stability. Specifically including marine engineering, chemical industry, aerospace and energy fields, such as seawater treatment equipment, chemical valves, aircraft engine components, etc.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China