0

0

Products Description

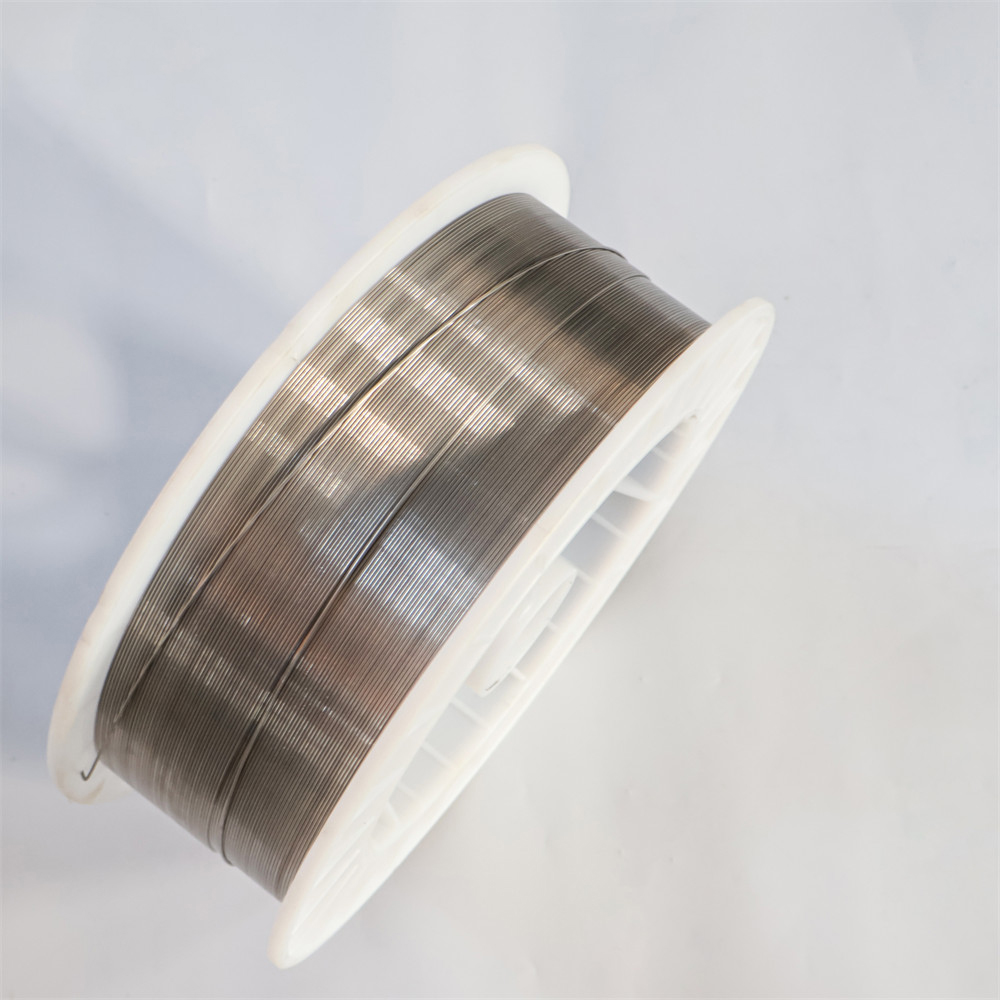

HC-276 thermal spray wire is a commonly used coating material based on nickel-based alloys with excellent corrosion resistance and chemical stability. Its main components are nickel, molybdenum, chromium and molybdenum. The content of molybdenum is relatively high, usually more than 15%, and it also contains small amounts of iron and cobalt. The diameter of this thermal spray wire is usually between 0.8mm and 3.2mm, and it has good tensile strength, usually between 600MPa and 800MPa. Its melting point is approximately 1325°C (2417°F) and is stable in high temperature environments.

In addition to corrosion resistance and chemical stability, HC-276 thermal spray wire also has excellent oxidation resistance and high temperature resistance, and is suitable for applications in high temperature, high pressure and highly corrosive environments. In addition, it also has good processability and weldability, making it easy to form a uniform and dense coating on the surface of components with complex structures.

HC-276 thermal spray wire is widely used in the chemical industry, petrochemical industry, marine engineering and energy fields. For example, it plays an important role in the coating protection of chemical equipment, oil drilling equipment, offshore platform structures, etc. Its excellent performance makes it one of the coating protection materials in demanding environments.

Thermal spray wire series: Inconel 625, 45CT, Ni95Al5, Monel 400, Monel K500, Hastelloy C276, Cr20Ni80, pure zinc wire

Specification

Item | Inconel 625 | Ni95Al5 | 45CT | Monel 400 | Monel K500 | HC-276 | Cr20Ni80 |

C | ≤0.05 | ≤0.02 | 0.01-0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 |

Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.06 |

P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 |

S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 |

Cr | 21.5-23 | ≤0.2 | 42-46 | -- | -- | 14.5-16 | 20-23 |

Ni | rest | rest | rest | 65-67 | rest | rest | rest |

Cu | -- | -- | -- | rest | 27-33 | -- | -- |

Mo | 8.5-10 | -- | -- | -- | -- | 15-17 | -- |

Ti | ≤0.4 | 0.4-1 | 0.3-1 | 2.0-3 | 0.35-0.85 | -- | -- |

Al | ≤0.4 | 4-5 | -- | ≤0.5 | 2.3-3.15 | -- | -- |

Fe | ≤1.0 | -- | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | -- |

Nb | 3.5-4.15 | -- | -- | -- | -- | -- | ≤1.0 |

| Co | -- | -- | -- | -- | -- | -- | -- |

V | -- | -- | -- | -- | -- | ≤0.35 | -- |

W | -- | -- | -- | -- | -- | 3.0-4.5 | -- |

Impurities | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

For more details, pls directly contact us.

Alloy Properties

chemical composition:

HC-276 alloy is mainly composed of nickel (Ni), chromium (Cr), molybdenum (Mo) and iron (Fe), and also contains small amounts of tungsten (W) and cobalt (Co). This unique chemical composition gives it excellent corrosion resistance.

Main features:

Excellent corrosion resistance: HC-276 has extremely high resistance to a variety of corrosive media, including oxidizing acids, reducing acids, seawater and chloride-containing environments.

Resistance to pitting and crevice corrosion: The high molybdenum and chromium content make HC-276 extremely resistant to pitting and crevice corrosion in high chloride environments.

High Temperature Stability: HC-276 maintains its corrosion-resistant properties even at high temperatures up to 1100°F (593°C).

Good weldability: HC-276 alloy has good weldability and its corrosion resistance will not be significantly reduced after welding.

Thermal spray wire application

Overview:

HC-276 thermal spray wire is applied to the surface of metal substrates through thermal spray technology to form a corrosion-resistant coating to improve the service life and performance of components.

Application areas:

Chemistry and petrochemicals: Coatings for chemical vessels, reactors, heat exchangers and pipes to resist corrosion from acidic and alkaline media.

Seawater and Marine Engineering: Coatings for ships, offshore platforms, pumps and valves to protect against seawater corrosion.

Flue gas desulfurization system: In desulfurization systems, HC-276 coating is resistant to sulfuric acid and sulfate corrosion.

Pulp and Paper Industry: Coating of chemical containers and equipment to resist attack by acidic media and oxidants.

Nuclear Industry: In the nuclear industry, HC-276 coatings are used to resist corrosion from radioactive materials and high-temperature steam.

Thermal spray technology advantages

Coating uniformity: Thermal spray technology can form a uniform coating and improve the corrosion resistance of parts.

Strong adhesion: HC-276 thermal spray wire coating has strong bonding force with the substrate and is not easy to fall off.

Flexibility: Thermal spray technology is suitable for parts of all shapes and sizes, providing great flexibility.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China