0

0

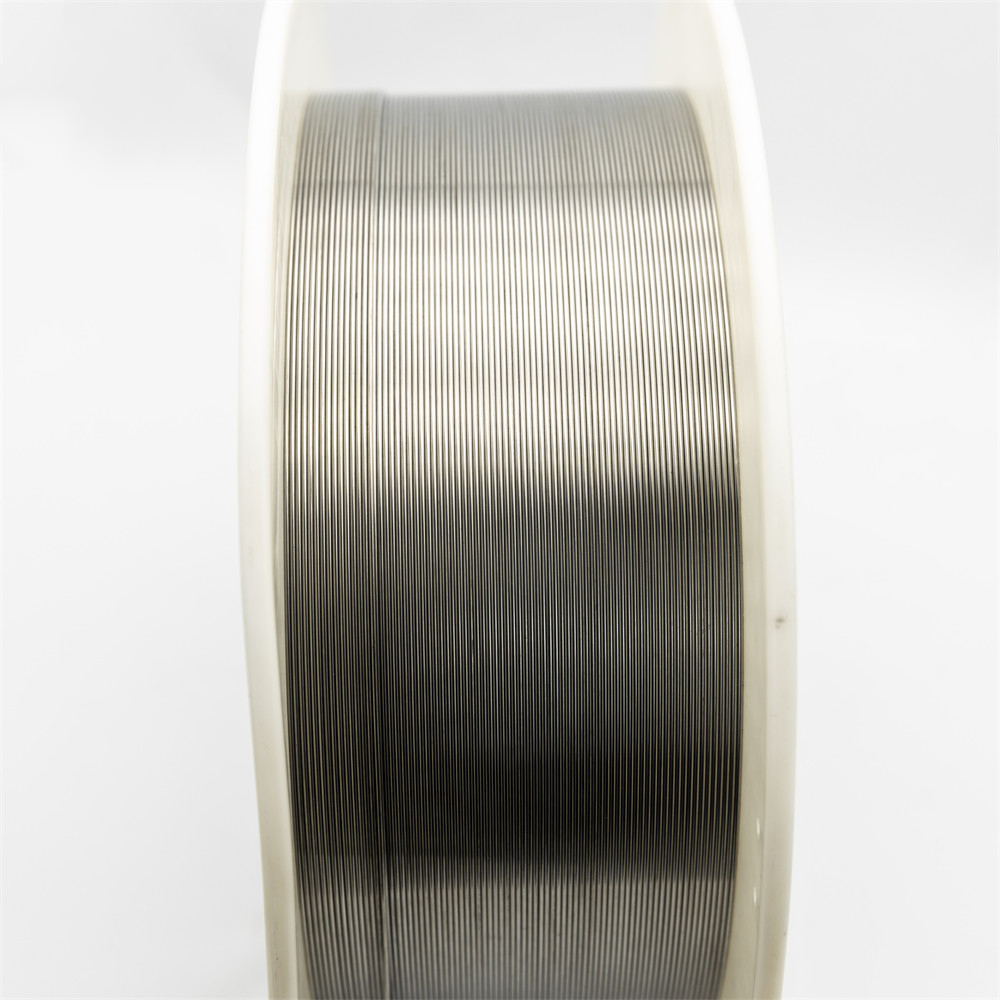

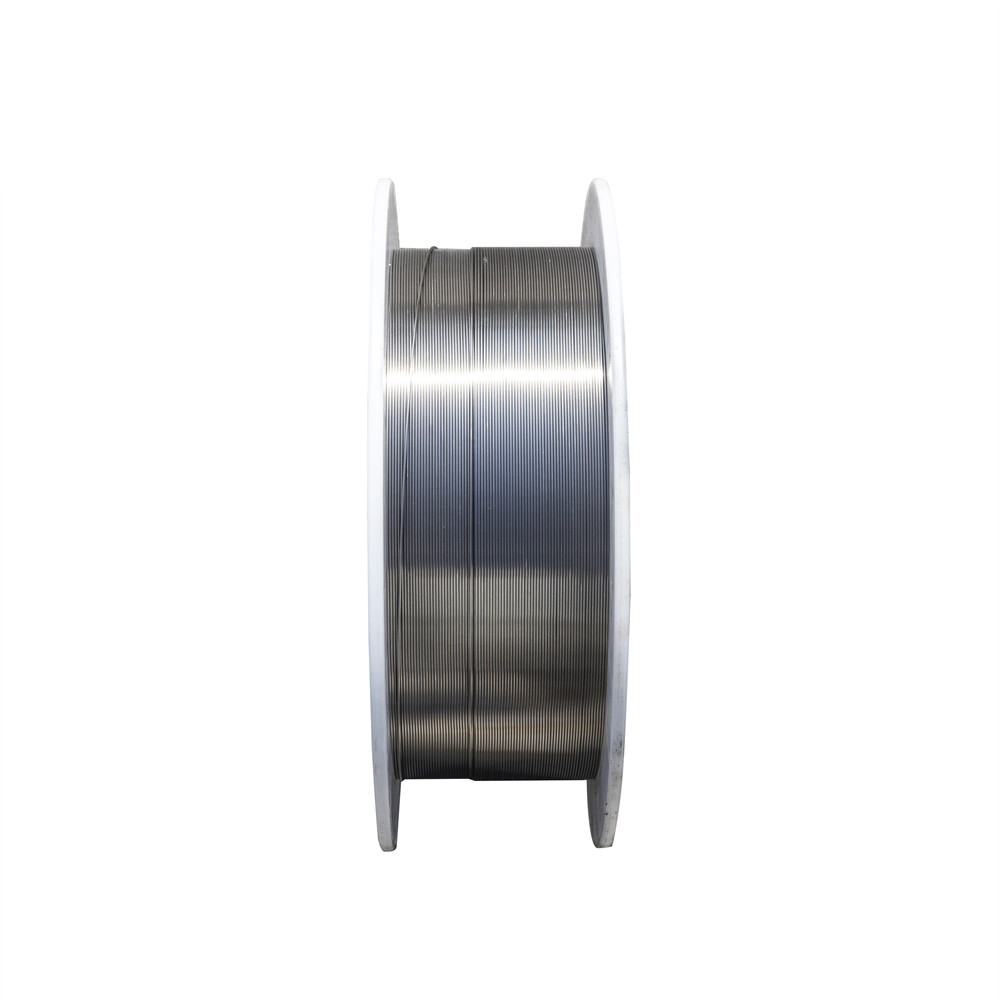

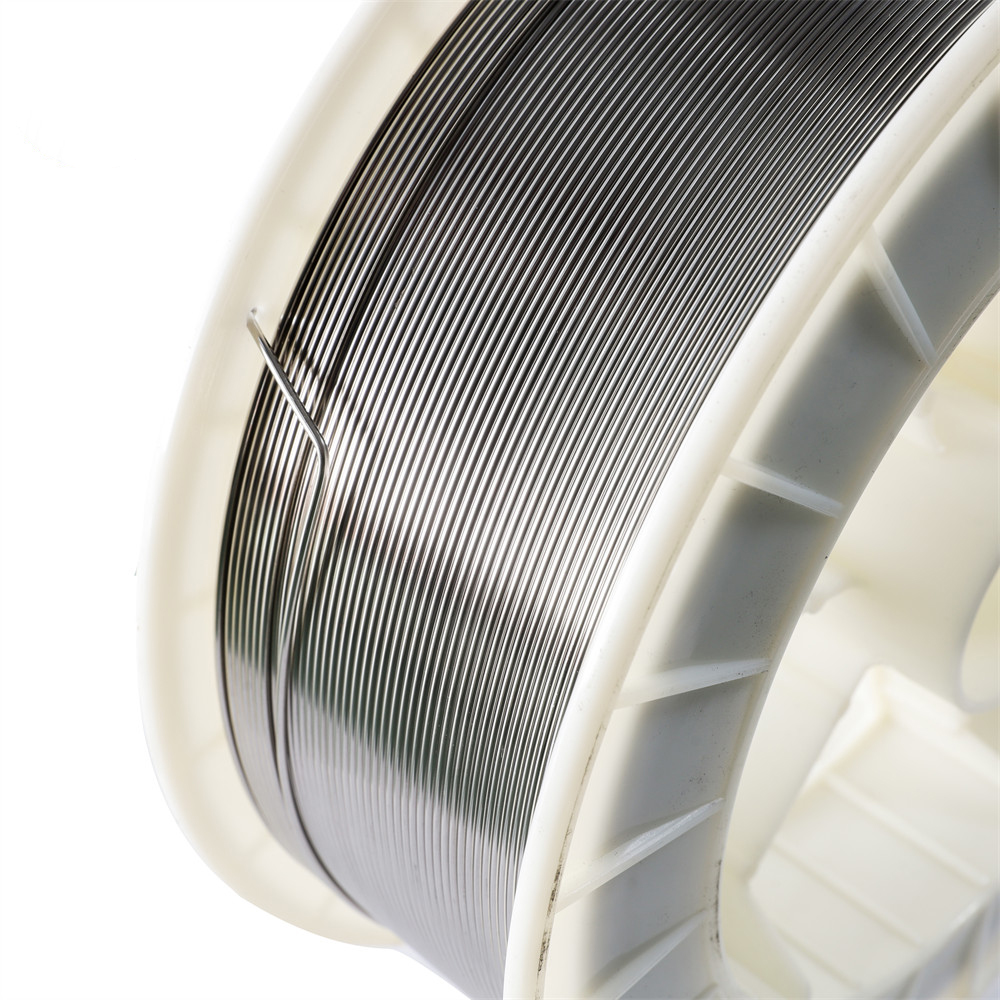

Products Description

Ni95Al5 thermal spray wire plays an important role in the aerospace field, and its excellent high-temperature performance and corrosion resistance make it an ideal choice for protecting critical components. This coating material based on nickel aluminum alloy can provide reliable protection under extreme conditions, protecting aerospace equipment from high temperature, corrosion, and oxidation, thereby extending its service life and improving performance.

In aerospace applications, Ni95Al5 thermal spray wire is commonly used for surface coating of critical components such as turbines, jet engines, and turbine blades. These components are subjected to extreme temperatures and pressures during flight, thus requiring excellent high-temperature resistance and antioxidant capacity. The oxide layer formed by Ni95Al5 coating can effectively prevent further oxidation of the substrate, while providing good thermal isolation performance, which helps maintain the stable working temperature of the components.

In addition, the Ni95Al5 coating also has good adhesion and wear resistance, which can resist external environmental factors such as wind pressure, airflow, and mechanical vibration, ensuring the reliability and safety of aerospace equipment. Due to its chemical inertness, it can also perform well in extreme chemical environments, enhancing its applicability in the aerospace field.

Thermal spray wire series: Inconel 625, 45CT, Ni95Al5, Monel 400, Monel K500, Hastelloy C276, Cr20Ni80, pure zinc wire

Specification

Item | Inconel 625 | Ni95Al5 | 45CT | Monel 400 | Monel K500 | HC-276 | Cr20Ni80 |

C | ≤0.05 | ≤0.02 | 0.01-0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 |

Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.06 |

P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 |

S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 |

Cr | 21.5-23 | ≤0.2 | 42-46 | -- | -- | 14.5-16 | 20-23 |

Ni | rest | rest | rest | 65-67 | rest | rest | rest |

Cu | -- | -- | -- | rest | 27-33 | -- | -- |

Mo | 8.5-10 | -- | -- | -- | -- | 15-17 | -- |

Ti | ≤0.4 | 0.4-1 | 0.3-1 | 2.0-3 | 0.35-0.85 | -- | -- |

Al | ≤0.4 | 4-5 | -- | ≤0.5 | 2.3-3.15 | -- | -- |

Fe | ≤1.0 | -- | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | -- |

Nb | 3.5-4.15 | -- | -- | -- | -- | -- | ≤1.0 |

| Co | -- | -- | -- | -- | -- | -- | -- |

V | -- | -- | -- | -- | -- | ≤0.35 | -- |

W | -- | -- | -- | -- | -- | 3.0-4.5 | -- |

Impurities | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

For more details, pls directly contact us.

Main features:

High temperature oxidation resistance: Ni95Al5 alloy can form a dense alumina (Al2O3) film at high temperatures, which can effectively prevent further oxidation and protect the stability of the alloy in high temperature environments.

High strength and lightweight: Nickel based alloys typically have high strength, and the addition of aluminum helps reduce the density of the alloy, which is crucial for aerospace components.

Good thermal stability: Ni95Al5 maintains its physical properties over a wide temperature range, making it suitable for temperature fluctuations in aerospace applications.

Excellent thermal shock resistance: Due to the high thermal conductivity of aluminum, Ni95Al5 has excellent thermal shock resistance and is suitable for aerospace components that frequently undergo rapid temperature changes.

Application of thermal spraying wire

The Ni95Al5 thermal spray wire through thermal spray technology is applied to the surface of aerospace components to improve their performance.

Specific application areas:

Engine components: Ni95Al5 coating can be used for hot end components of engines, such as turbine blades and combustion chambers, to improve their resistance to high temperatures and oxidation resistance.

Spacecraft thermal protection system: During the re-entry process of spacecraft, Ni95Al5 coating can be used as part of the thermal protection system to protect the spacecraft from high-temperature erosion.

Fuel system: Due to its corrosion resistance, Ni95Al5 coating can be used for pumps and valves in fuel systems to prevent fuel corrosion.

Aircraft brakes: Ni95Al5 coating can be applied to brakes to improve their wear resistance and oxidation resistance at high temperatures.

Advantages of thermal spraying technology

The combination of coating and substrate: Thermal spraying technology can firmly bond Ni95Al5 coating with various substrates, providing long-lasting protection.

Uniformity of coating: Thermal spray wire technology can form a uniform coating, ensuring the protection of the entire surface of the component.

Adaptability: Thermal spraying technology can adapt to various complex shaped components, including precision components in the aerospace field.

Conclusion

Ni95Al5 thermal spray wire has enormous application potential in the aerospace field due to its excellent high-temperature performance and lightweight characteristics. With the development of aerospace technology and the increasing demand for high-performance materials, Ni95Al5 thermal spray wire is expected to play a more important role in the future manufacturing and maintenance of aerospace components.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China