0

0

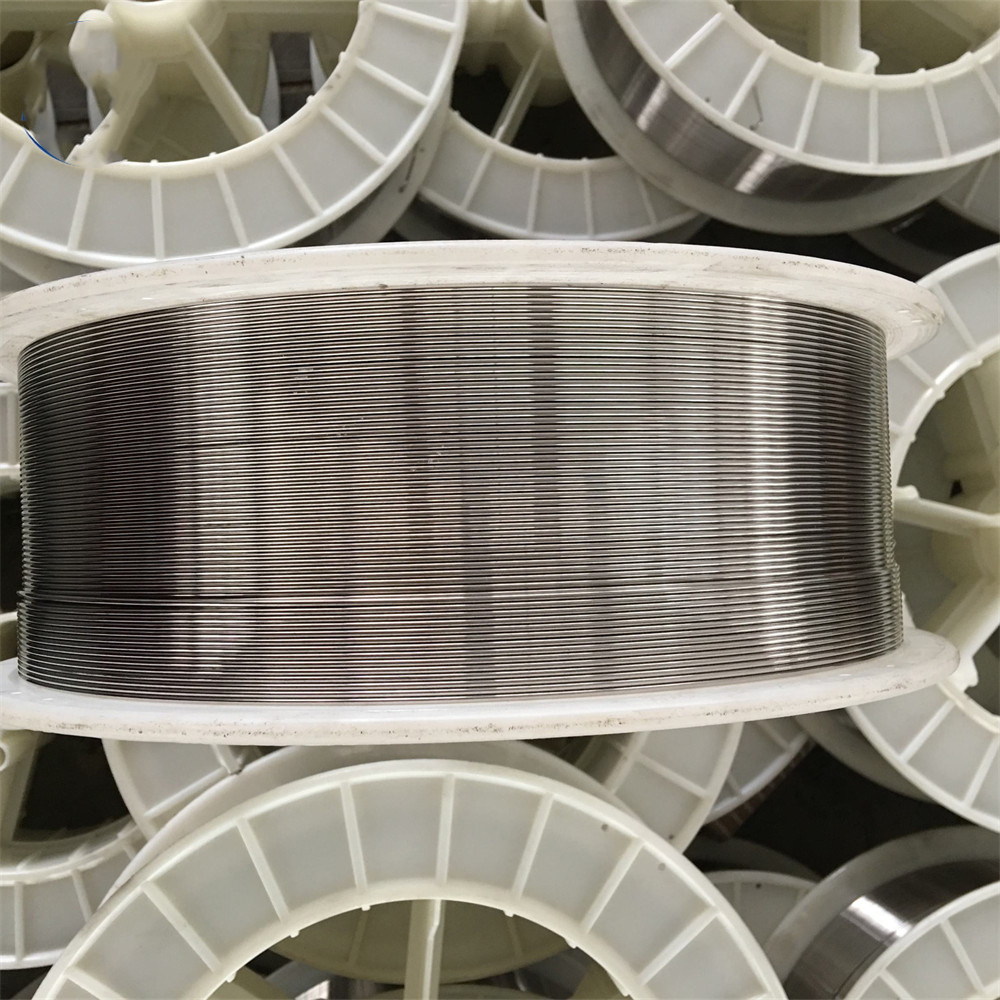

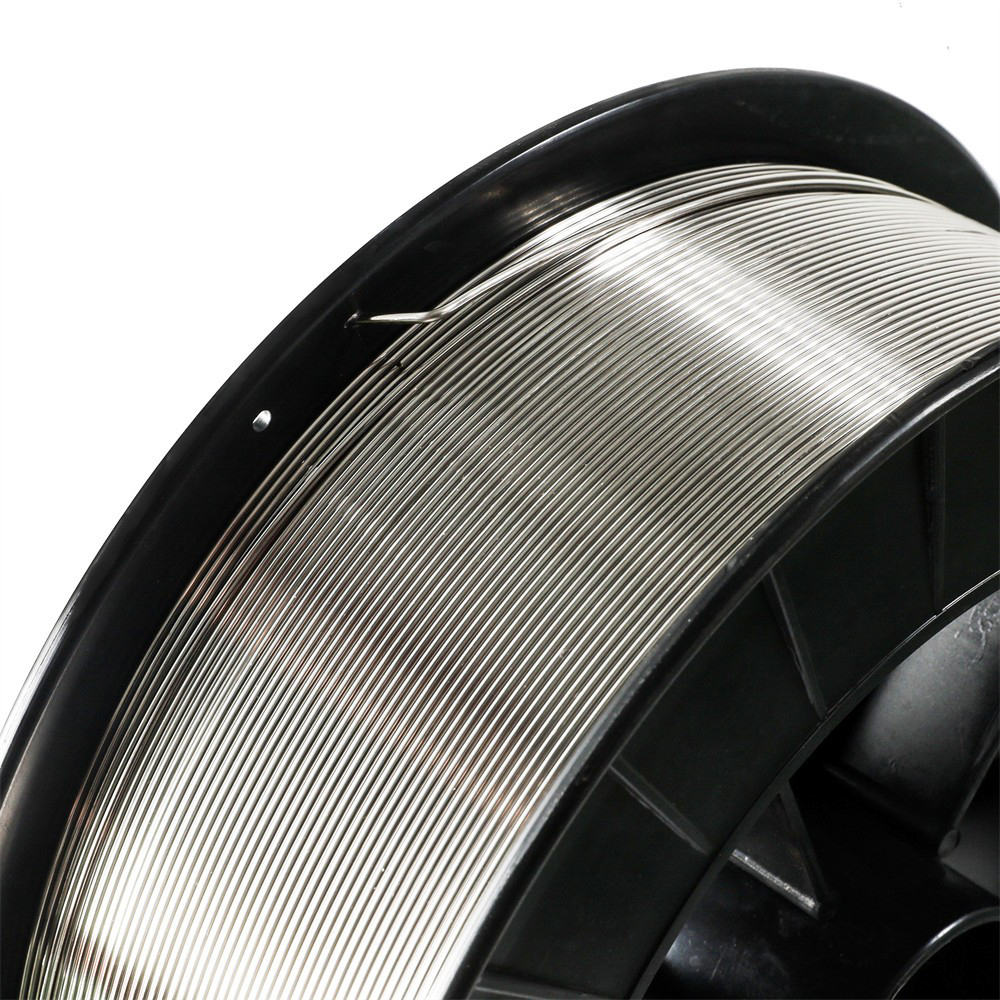

Products Description

Inconel 625 thermal spray wire is an excellent high-temperature, high-pressure, corrosion-resistant alloy that plays an important role in the industrial field. Its excellent high temperature resistance enables it to work stably under extreme temperature conditions for a long time.

At the same time, its excellent corrosion resistance makes it an ideal choice in chemical industry, marine engineering and other fields. In addition, Inconel 625 has high strength and good weldability, which can meet the engineering requirements for strength and connectivity.

It is widely used in aerospace, chemical industry, marine engineering, energy and automobile fields, such as aerospace engines, chemical equipment, seawater anti-corrosion coatings, gas turbine thermal insulation coatings and anti-corrosion coatings for automobile exhaust systems, etc.

Inconel 625 thermal spray wire has become one of the indispensable materials in engineering design due to its diverse applications and excellent performance characteristics.

Thermal spray wire series: Inconel 625, 45CT, Ni95Al5, Monel 400, Monel K500, Hastelloy C276, Cr20Ni80, pure zinc wire

Specification

Item | Inconel 625 | Ni95Al5 | 45CT | Monel 400 | Monel K500 | HC-276 | Cr20Ni80 |

C | ≤0.05 | ≤0.02 | 0.01-0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 |

Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.06 |

P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 |

S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 |

Cr | 21.5-23 | ≤0.2 | 42-46 | -- | -- | 14.5-16 | 20-23 |

Ni | rest | rest | rest | 65-67 | rest | rest | rest |

Cu | -- | -- | -- | rest | 27-33 | -- | -- |

Mo | 8.5-10 | -- | -- | -- | -- | 15-17 | -- |

Ti | ≤0.4 | 0.4-1 | 0.3-1 | 2.0-3 | 0.35-0.85 | -- | -- |

Al | ≤0.4 | 4-5 | -- | ≤0.5 | 2.3-3.15 | -- | -- |

Fe | ≤1.0 | -- | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | -- |

Nb | 3.5-4.15 | -- | -- | -- | -- | -- | ≤1.0 |

| Co | -- | -- | -- | -- | -- | -- | -- |

V | -- | -- | -- | -- | -- | ≤0.35 | -- |

W | -- | -- | -- | -- | -- | 3.0-4.5 | -- |

Impurities | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

For more details, pls directly contact us.

Feature

Excellent high temperature resistance: Inconel 625 performs well in high temperature environments and its stability allows it to operate in extreme temperature conditions for long periods of time, making it ideal for high temperature applications. Whether it is high-temperature components in aerospace engines or high-temperature reaction vessels in chemical equipment, Inconel 625 can maintain stable performance.

Excellent corrosion resistance: The alloy has excellent corrosion resistance and can resist the erosion of various chemical media and seawater. This makes it widely used in marine engineering, chemical equipment and acid-base environments, providing reliable guarantee for the long-term stable operation of equipment.

High strength and good weldability: Inconel 625 has excellent strength and good weldability, which allows it to meet the requirements for strength and connectivity in engineering design. Whether it's components that need to withstand high pressures or components that require complex connections, Inconel 625 is up to the task.

Highly customizable: The characteristics of Inconel 625 thermal spray filament can be adjusted and customized according to specific application needs. Whether it is corrosion resistance requirements for a specific chemical environment or high temperature resistance performance requirements for a specific temperature range, customized solutions can be achieved by adjusting the alloy composition and processing technology.

Application

Aerospace field: In the aerospace field, Inconel 625 is often used to manufacture high-temperature parts of aerospace engines, such as turbine blades, combustion chambers, nozzles, etc. Its excellent high temperature resistance and corrosion resistance enable it to maintain stable performance in high temperature, high pressure, and harsh aviation environments, ensuring the safe operation of aircraft.

Chemical industry: In the chemical industry, Inconel 625 is widely used in the manufacture of chemical equipment, such as reaction vessels, pipes, valves, etc. Its excellent corrosion resistance enables it to operate stably for a long time in various corrosive media, ensuring the safety and reliability of the chemical production process.

Marine engineering field: In the marine engineering field, Inconel 625 is often used as a material for seawater anti-corrosion coatings, such as seawater treatment equipment, offshore drilling platforms, etc. Its excellent resistance to seawater corrosion can effectively extend the service life of equipment, reduce maintenance costs, and ensure the safe and stable operation of marine engineering facilities.

Energy field: In the energy field, Inconel 625 is often used to manufacture thermal insulation coatings for gas turbines and key components in nuclear energy facilities. Its excellent high temperature resistance and high strength enable it to withstand the impact of high temperature, high pressure, and high speed fluids, ensuring the efficient operation of energy facilities.

Automotive field: In the automotive field, Inconel 625 is often used to make anti-corrosion coatings for automobile exhaust systems to extend the service life of the exhaust system, reduce failures and damage caused by corrosion, and improve the reliability and safety of automobiles. sex.

Q&A

Q: What is the main chemical composition of Inconel 625 thermal spray wire?

Answer: The main chemical components of Inconel 625 alloy include nickel (Ni), chromium (Cr), iron (Fe), molybdenum (Mo) and niobium (Nb), of which the nickel content usually exceeds 50%. The combination of these elements gives Inconel 625 excellent high temperature performance and corrosion resistance.

Q: In what fields is Inconel 625 thermal spray wire widely used?

Answer: Inconel 625 thermal spray wire is widely used in aerospace, chemical industry, marine engineering, energy and automotive fields. Specifically, it includes the manufacturing of high-temperature parts for aircraft engines, the manufacturing of chemical equipment, the application of seawater anti-corrosion coatings, the manufacturing of thermal insulation coatings for gas turbines, and the anti-corrosion coatings of automobile exhaust systems.

Q: How does the thermal expansion coefficient of Inconel 625 thermal spray wire compare to steel?

Answer: The thermal expansion coefficient of Inconel 625 alloy is close to that of steel, which means that during the thermal spraying process, the thermal expansion between the coating and the substrate is better matched, which helps to reduce coating peeling and cracking caused by thermal stress. phenomenon, improving the adhesion and stability of the coating.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China