0

0

Products Description

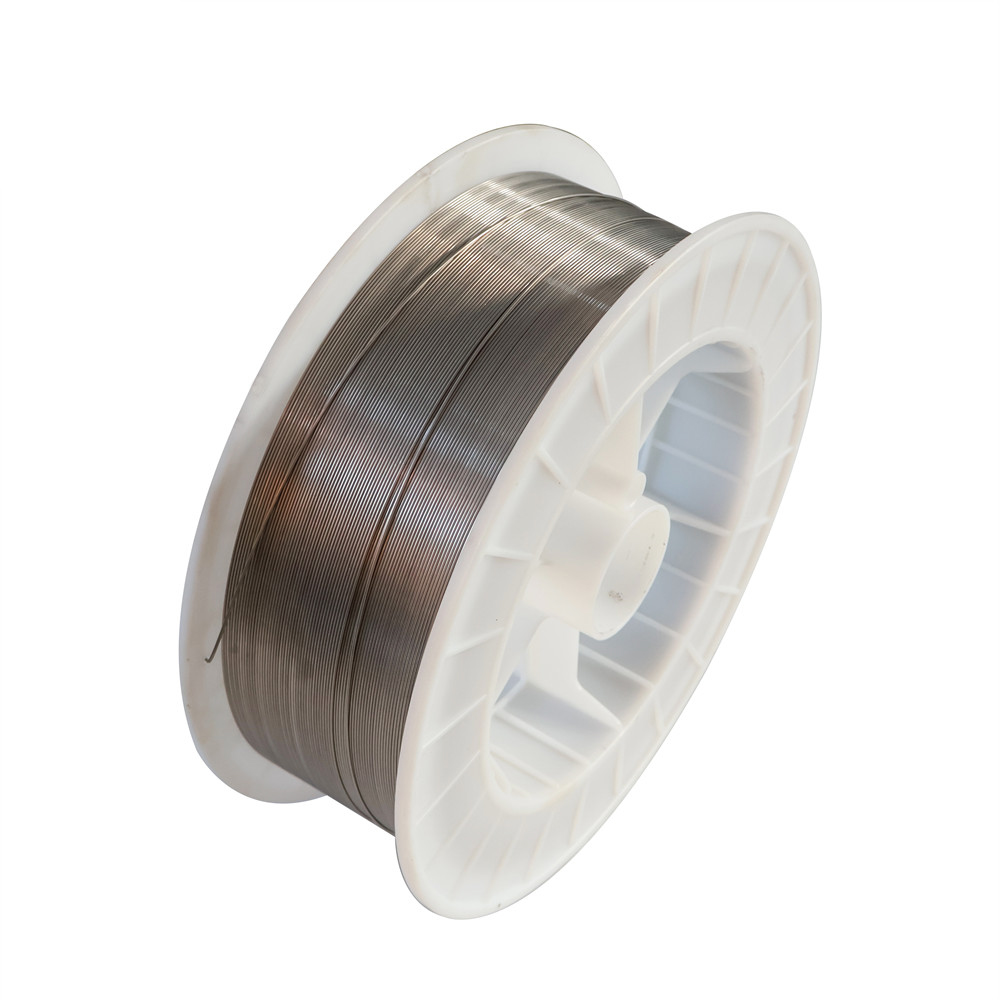

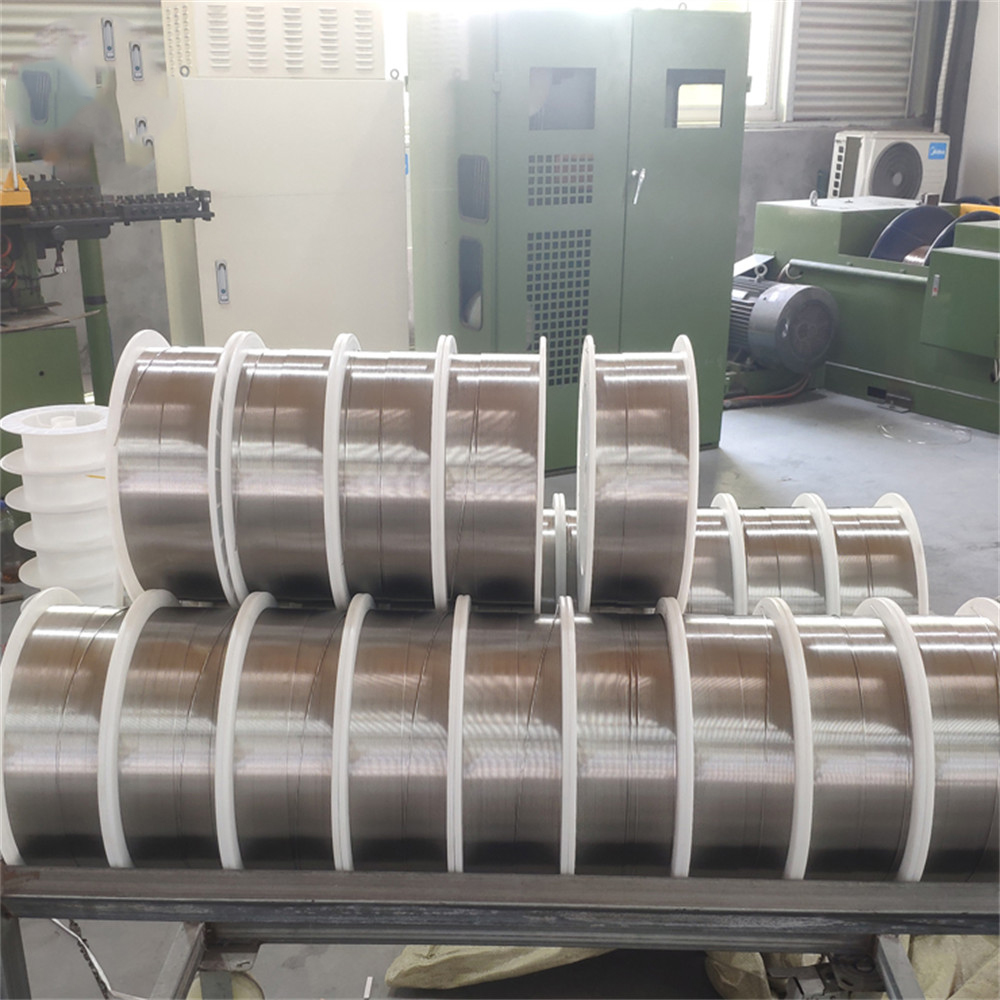

Cr20Ni80 thermal spray wire is a commonly used nickel chromium alloy coating material, which mainly consists of nickel (Ni) and chromium (Cr). It has a high chromium content, usually exceeding 20%, and a nickel content of about 80%. The diameter of this thermal spray wire is usually between 0.8mm and 3.2mm, and it has good high-temperature performance and oxidation resistance.

The Cr20Ni80 thermal spray wire performs well in high-temperature environments and can work stably for a long time under high temperature conditions. Its excellent antioxidant performance can effectively prevent oxidation corrosion at high temperatures. Due to its excellent high-temperature performance, Cr20Ni80 thermal spray wire is widely used in the field of thermal industry, such as protective coatings for furnace heating elements, heating tubes, furnaces, etc.

In addition, Cr20Ni80 thermal spray wire also has good mechanical and wear resistance properties, suitable for some engineering applications that require wear and corrosion resistance. It is widely used in industries such as chemical, metallurgical, and glass to protect the surface of equipment from high temperature and corrosion, and to extend the service life of equipment.

Thermal spray wire series: Inconel 625, 45CT, Ni95Al5, Monel 400, Monel K500, Hastelloy C276, Cr20Ni80, pure zinc wire

Specification

Item | Inconel 625 | Ni95Al5 | 45CT | Monel 400 | Monel K500 | HC-276 | Cr20Ni80 |

C | ≤0.05 | ≤0.02 | 0.01-0.1 | ≤0.04 | ≤0.25 | ≤0.02 | ≤0.08 |

Mn | ≤0.4 | ≤0.2 | ≤0.2 | 2.5-3.5 | ≤1.5 | ≤1.0 | ≤0.06 |

P | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.02 |

S | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 | ≤0.01 |

Si | ≤0.15 | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.5 | ≤0.08 | 0.75-1.6 |

Cr | 21.5-23 | ≤0.2 | 42-46 | -- | -- | 14.5-16 | 20-23 |

Ni | rest | rest | rest | 65-67 | rest | rest | rest |

Cu | -- | -- | -- | rest | 27-33 | -- | -- |

Mo | 8.5-10 | -- | -- | -- | -- | 15-17 | -- |

Ti | ≤0.4 | 0.4-1 | 0.3-1 | 2.0-3 | 0.35-0.85 | -- | -- |

Al | ≤0.4 | 4-5 | -- | ≤0.5 | 2.3-3.15 | -- | -- |

Fe | ≤1.0 | -- | ≤0.5 | ≤1.0 | ≤1.0 | 4.0-7.0 | -- |

Nb | 3.5-4.15 | -- | -- | -- | -- | -- | ≤1.0 |

| Co | -- | -- | -- | -- | -- | -- | -- |

V | -- | -- | -- | -- | -- | ≤0.35 | -- |

W | -- | -- | -- | -- | -- | 3.0-4.5 | -- |

Impurities | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.5 |

For more details, pls directly contact us.

Main features:

Good corrosion resistance: Due to the presence of chromium, Cr20Ni80 has good corrosion resistance to oxidizing acids and certain organic acids.

High temperature stability: The high nickel content allows the alloy to maintain its structure and properties at high temperatures, making it suitable for high-temperature working environments.

Excellent heat resistance: Cr20Ni80 can withstand continuous high temperatures and is commonly used in high-temperature furnace linings and heat treatment equipment.

Easy to process: Due to the high content of nickel, Cr20Ni80 alloy has good processability and can be easily applied to various substrates through thermal spraying technology.

Application of thermal spraying wire

The Cr20Ni80 thermal spraying wire is applied to the surface of metal substrates through thermal spraying technology, forming a layer of corrosion-resistant and heat-resistant coating.

Application field:

Chemical industry: Cr20Ni80 coating is used in chemical containers, reactors, and heat exchangers to resist corrosion from chemical media.

Energy industry: Apply Cr20Ni80 coating on high-temperature components such as boilers, burners, and high-temperature pipelines to improve their heat and corrosion resistance.

Automotive exhaust system: Due to its high temperature and corrosion resistance, Cr20Ni80 coating is suitable for components of automotive exhaust systems, such as silencers and catalytic converters.

Food processing equipment: Cr20Ni80 coating can also be used in food processing equipment because it is not only corrosion-resistant, but also meets food safety standards.

Advantages of thermal spraying technology

Coating uniformity: Thermal spraying technology can form a uniform and dense coating, effectively isolating corrosive media.

Strong adhesion: The Cr20Ni80 thermal spray coating has good adhesion with various substrates, ensuring the durability of the coating.

Flexibility: Thermal spraying technology is suitable for complex shaped components, providing great flexibility and application range.

Conclusion

Cr20Ni80 thermal spray wire has shown its unique value in many industrial applications due to its excellent corrosion resistance and heat resistance. With the continuous development of thermal spraying technology, the application prospects of Cr20Ni80 thermal spraying wire will be more extensive, providing more possibilities for surface protection of industrial components.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China