0

0

Products Description

1P 2P 3P 4P 5P 6P pure nickel strip for 18650 28650 32650 lithium battery pack spot weld

Pure nickel ribbon has important applications in the nuclear industry. Due to its excellent high-temperature stability and corrosion resistance, pure nickel strip is widely used in the manufacture of key components such as nuclear reactor parts and nuclear fuel elements in nuclear power plants. Under the special requirements of the nuclear energy field, pure nickel ribbons can withstand high temperatures and strong radiation environments, maintaining the stability and reliability of their materials. It plays a key role in the nuclear industry, ensuring the safe operation of nuclear reactors and the stability of nuclear fuel. The application of pure nickel belts provides high-performance, high-reliability material solutions for the nuclear energy field and makes an important contribution to sustainable clean energy production.

Features

High temperature strength: Pure nickel tape has excellent high temperature strength and can maintain good mechanical properties in high temperature and high radiation environments.

Radiation resistance: Pure nickel belts have high resistance to nuclear radiation and can operate stably for a long time in radiation environments such as nuclear reactors.

Corrosion resistance: Pure nickel belt has good resistance to common corrosive media in the nuclear industry, including acidic, alkaline and oxidizing media.

Advantage:

High temperature oxidation resistance: Pure nickel belt has good high temperature oxidation resistance, which can prevent thermal oxidation reaction in high temperature environment and protect the safe operation of nuclear equipment.

Radiation resistance: Pure nickel tape has high resistance in nuclear radiation environment, can maintain the physical and chemical properties of the material, and maintain structural stability under radiation conditions.

Corrosion resistance: Pure nickel belts can resist corrosive media in the nuclear industry, reducing material corrosion losses and equipment maintenance frequency.

Functions / Applications

Nuclear reactor components: Pure nickel ribbon can be used to manufacture components in nuclear reactors, such as fuel elements, reactor pressure vessels, and pipes. Its high temperature strength and corrosion resistance allow it to withstand the high temperature and high radiation environment of nuclear reactors.

Nuclear fuel processing equipment: Pure nickel belts can be used for equipment in the nuclear fuel processing process, such as enrichment equipment and solvent extraction equipment. Its corrosion resistance and high temperature strength enable it to withstand the corrosive and high temperature conditions of nuclear fuel processing fluids.

Nuclear waste treatment equipment: Pure nickel tape can be used in nuclear waste treatment equipment, such as storage tanks, transfer containers and treatment facilities. Its corrosion resistance and radiation resistance allow it to safely handle and store nuclear waste.

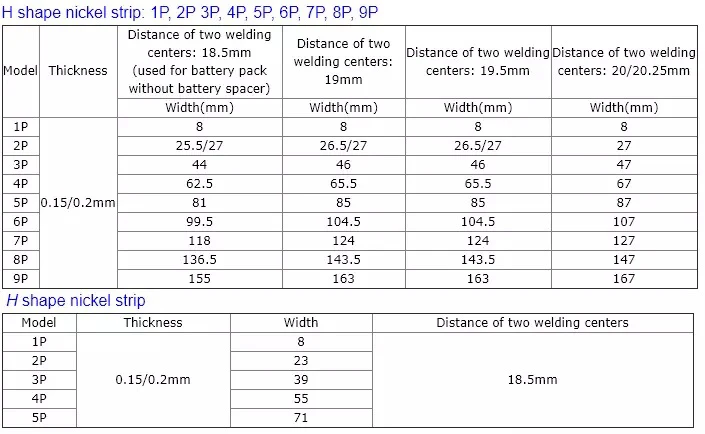

Dimension

The thickness and dimensions can be met what customers required.

Specification

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

| Type | Dimension(mm) | Cell Spacing:(mm) | Width | Dimension of the Square hole (mm) | Nickel Plated Steel Strip | Pure Nickel | Type of Battery Pack | |

| Length for per kg (m) | with holder | without holder | ||||||

| 1P 18650 Nickel strip | 0.15*7*18.4 | 18.4 | 7 | 一 | 128.3 | 112.6 | √ | |

| 0.15*7*19 | 19 | 一 | 127.9 | 112.1 | √ | |||

| 0.15*7*19.5 | 19.5 | 一 | √ | |||||

| 0.15*7*20.25 | 20.25 | 一 | 127.6 | 111.9 | √ | |||

| 2P 18650 Nickel strip | 0.15*26*19(13.5*13.5) | 19 | 26 | 12*12 | 47.2 | 41.4 | √ | |

| 0.15*27*19.5(12*14.5) | 19.5 | 27 | 12*14.5 | 48.9 | 42.9 | √ | ||

| 0.15*27*19.75(12.5*12.5) | 19.75 | 12.5*12.5 | 47 | 41.2 | √ | |||

| 0.15*27*20.25(13.5*13.5) | 20.25 | 13.5*13.5 | 48.9 | 42.9 | √ | |||

| 2P 18650 Nickel strip | 0.15*25.5*18.4(11*12.5) | 18.4 | 25.5 | 11*12.5 | 48.9 | 42.9 | √ | |

| Dislocation 2P 18650 Nickel strip | 0.15*25.5*18.4(8*9.5) | 18.4 | 8*9.5 | 41.1 | 36.1 | √ | ||

| Dislocation 2P 18650 Nickel strip | 0.15*25.5*19.5(8*9.5) | 19.5 | 8*9.5 | 38.6 | 33.8 | √ | ||

| 3P 18650 Nickel strip | 0.15*44.5*18.4(11*12.5) | 18.4 | 44.5 | 11*12.5 | 27.4 | 24 | √ | |

| 0.15*45*19(12*12) | 19 | 45 | 12*12 | 29.1 | 25.5 | √ | ||

| 0.15*47.5*20.15(12.65*12.65) | 20.15 | 47.5 | 12.6.5*12.65 | 27.4 | 24 | √ | ||

| 0.15*47.5*20.25(13.5*13.5) | 20.25 | 13.5*13.5 | 29.4 | 25.7 | √ | |||

| 4P 18650 Nickel strip | 0.15*63*18.5 (11*12.5) | 18.5 | 63 | 11*12.5 | 21.6 | 18.9 | √ | |

| 0.15*64*19(12*12) | 19 | 64 | 12*12 | 21 | 18.4 | √ | ||

| 0.15*67.95*20.15(12.65*12.65) | 20.15 | 67.95 | 12.65*12.65 | 19.6 | 17.2 | √ | ||

| 0.15*67.7*20.25(13.5*13.5) | 20.25 | 67 | 13.5*13.5 | 21.3 | 18.7 | √ | ||

| 5P 18650 Nickel strip | 0.15*83*19(12*12) | 19 | 83 | 12*12 | 16.4 | 14.4 | √ | |

| 0.15*88.1*20.15(12.65*12.65) | 20.15 | 88.1 | 12.65*12.65 | 19.7 | 17.3 | √ | ||

| 0.15*87.9*20.25(13.5*13.5) | 20.25 | 87.9 | 13.5*13.5 | 16.7 | 14.6 | √ | ||

| 6P 18650 Nickel strip | 0.15*102*19(12*12) | 19 | 102 | 12*12 | 13.5 | 11.9 | √ | |

| 0.15*108.25*20.15 | 20.15 | 108.25 | 12.65*12.65 | 12.6 | 11 | √ | ||

| 0.15*108.1*20.25(13.5*13.5) | 20.25 | 108.1 | 13.5*13.5 | 13.7 | 12 | √ | ||

| 7P 18650 Nickel strip | 0.15*121*19(12*12) | 19 | 121 | 12*12 | 11.5 | 10 | √ | |

| 0.15*128.4*20.15(12.65*12.65) | 20.15 | 128.4 | 12.65*12.65 | 10.7 | 9.4 | √ | ||

| 0.15*128.3*20.25(13.5*13.5) | 20.25 | 128.3 | 13.5*13.5 | 11.6 | 10.2 | √ | ||

| 8P 18650 Nickel strip | 0.15*140*19(12*12) | 19 | 140 | 12*12 | 10 | 8.7 | √ | |

For more details, pls directly contact us.

Other relevant knowledge points:

Effects of nuclear radiation: Nuclear radiation has damaging effects on materials and equipment, including radiation damage, radiation-induced corrosion and changes in the physical properties of materials. Choosing the right materials is crucial to ensuring the safe operation of nuclear equipment.

High-temperature structural materials: In addition to pure nickel strips, there are other high-temperature structural materials such as ferritic stainless steel and nickel-based alloys, which are also widely used in the nuclear industry. These materials have high high-temperature strength and corrosion resistance and are suitable for use in areas such as nuclear reactors and nuclear fuel processing equipment.

Nuclear Industry Safety: The nuclear industry is a high-risk industry and safety is always of paramount importance. When designing and manufacturing nuclear equipment, it is necessary to strictly comply with relevant safety standards, including material selection, process control and safety management in the nuclear industry.

Q&A:

In what other fields are pure nickel strips commonly used?

In addition to the electronics industry, pure nickel strips are also commonly used in chemical industry, aviation and other fields, and are used to manufacture corrosion-resistant equipment, heating elements, batteries, etc.

What is the difference between pure nickel belt and nickel alloy belt?

Pure nickel belt is made of pure nickel, while nickel alloy belt is an alloy of nickel and other elements. Nickel alloy strips generally have higher strength and corrosion resistance and are suitable for more severe environmental conditions.

What are the market prospects for pure nickel strips in the electronics industry?

With the continuous development of the electronics industry, the requirements for high precision, stability and reliability are also increasing. Pure nickel belts have broad market prospects in the electronics industry.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China