0

0

Products Description

1P 2P 3P 4P 5P 6P pure nickel strip for 18650 28650 32650 lithium battery pack spot weld

Pure nickel strip plays an important role in shipbuilding. Due to its excellent corrosion resistance and high strength properties, pure nickel strips are widely used in ship manufacturing and equipment. It is commonly used in the manufacture of key components such as hull structures, ship piping systems, seawater coolers, propellers and ship propulsion systems. Pure nickel strips are able to withstand corrosion and high temperature conditions in the marine environment, ensuring long-term reliable operation of the ship. In addition, pure nickel strips also have good weldability and processability, making them easy to process and install during shipbuilding. The application of pure nickel strips provides durable and reliable material solutions for the shipbuilding industry and makes iortant contributions to the development of the marine transportation and shipping industries.

Features

Corrosion resistance: Pure nickel belts have good corrosion resistance to corrosive media such as seawater and salt spray, and can reduce corrosion losses of ships in marine environments.

High temperature strength: Pure nickel belt has high high temperature strength and can maintain stable performance in high temperature environments such as engines and exhaust systems.

Fatigue strength: Pure nickel strip has high fatigue strength and can withstand the stress of ships under long-term use and vibration loading.

Advantage:

Corrosion Resistance: The corrosion resistance of pure nickel strips in marine environments makes them ideal in shipbuilding to improve hull durability and maintenance intervals.

Lightweight and high-strength: Compared with some traditional ship materials, pure nickel belts have higher strength and lighter weight, which can reduce the ship's dead weight and improve load-carrying capacity and fuel efficiency.

High-temperature adaptability: The high-temperature strength of pure nickel tape makes it suitable for high-temperature environments such as ship engine systems and exhaust ducts, providing reliable performance and durability.

Functions / Applications

Hull structure: Pure nickel strips can be used in ship hull structures, such as hulls and plating. Its corrosion resistance and high strength help improve the ship's durability and resistance to corrosion.

Engine components: Pure nickel tape can be used in key components of ship engines, such as exhaust pipes, turbine blades and combustion chambers. Its high-temperature strength and corrosion resistance help improve engine performance and reliability.

Marine piping system: Pure nickel strips can be used in ship piping systems, including water supply and drainage systems, oil systems and gas systems. Its corrosion resistance and high-temperature strength help increase pipe life and reliability.

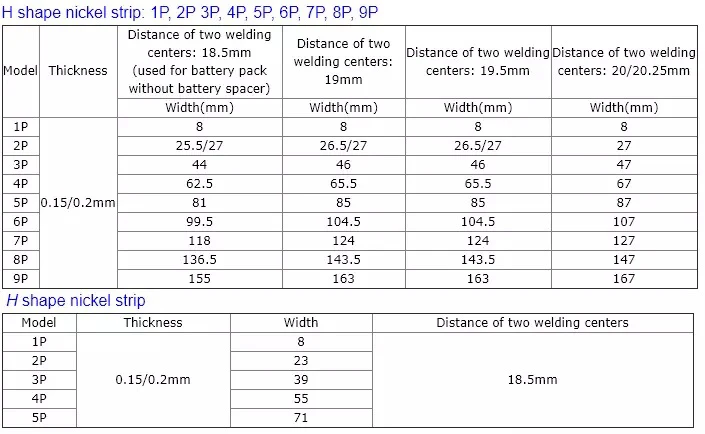

Dimension

The thickness and dimensions can be met what customers required.

Specification

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

| Type | Dimension(mm) | Cell Spacing:(mm) | Width | Dimension of the Square hole (mm) | Nickel Plated Steel Strip | Pure Nickel | Type of Battery Pack | |

| Length for per kg (m) | with holder | without holder | ||||||

| 1P 18650 Nickel strip | 0.15*7*18.4 | 18.4 | 7 | 一 | 128.3 | 112.6 | √ | |

| 0.15*7*19 | 19 | 一 | 127.9 | 112.1 | √ | |||

| 0.15*7*19.5 | 19.5 | 一 | √ | |||||

| 0.15*7*20.25 | 20.25 | 一 | 127.6 | 111.9 | √ | |||

| 2P 18650 Nickel strip | 0.15*26*19(13.5*13.5) | 19 | 26 | 12*12 | 47.2 | 41.4 | √ | |

| 0.15*27*19.5(12*14.5) | 19.5 | 27 | 12*14.5 | 48.9 | 42.9 | √ | ||

| 0.15*27*19.75(12.5*12.5) | 19.75 | 12.5*12.5 | 47 | 41.2 | √ | |||

| 0.15*27*20.25(13.5*13.5) | 20.25 | 13.5*13.5 | 48.9 | 42.9 | √ | |||

| 2P 18650 Nickel strip | 0.15*25.5*18.4(11*12.5) | 18.4 | 25.5 | 11*12.5 | 48.9 | 42.9 | √ | |

| Dislocation 2P 18650 Nickel strip | 0.15*25.5*18.4(8*9.5) | 18.4 | 8*9.5 | 41.1 | 36.1 | √ | ||

| Dislocation 2P 18650 Nickel strip | 0.15*25.5*19.5(8*9.5) | 19.5 | 8*9.5 | 38.6 | 33.8 | √ | ||

| 3P 18650 Nickel strip | 0.15*44.5*18.4(11*12.5) | 18.4 | 44.5 | 11*12.5 | 27.4 | 24 | √ | |

| 0.15*45*19(12*12) | 19 | 45 | 12*12 | 29.1 | 25.5 | √ | ||

| 0.15*47.5*20.15(12.65*12.65) | 20.15 | 47.5 | 12.6.5*12.65 | 27.4 | 24 | √ | ||

| 0.15*47.5*20.25(13.5*13.5) | 20.25 | 13.5*13.5 | 29.4 | 25.7 | √ | |||

| 4P 18650 Nickel strip | 0.15*63*18.5 (11*12.5) | 18.5 | 63 | 11*12.5 | 21.6 | 18.9 | √ | |

| 0.15*64*19(12*12) | 19 | 64 | 12*12 | 21 | 18.4 | √ | ||

| 0.15*67.95*20.15(12.65*12.65) | 20.15 | 67.95 | 12.65*12.65 | 19.6 | 17.2 | √ | ||

| 0.15*67.7*20.25(13.5*13.5) | 20.25 | 67 | 13.5*13.5 | 21.3 | 18.7 | √ | ||

| 5P 18650 Nickel strip | 0.15*83*19(12*12) | 19 | 83 | 12*12 | 16.4 | 14.4 | √ | |

| 0.15*88.1*20.15(12.65*12.65) | 20.15 | 88.1 | 12.65*12.65 | 19.7 | 17.3 | √ | ||

| 0.15*87.9*20.25(13.5*13.5) | 20.25 | 87.9 | 13.5*13.5 | 16.7 | 14.6 | √ | ||

| 6P 18650 Nickel strip | 0.15*102*19(12*12) | 19 | 102 | 12*12 | 13.5 | 11.9 | √ | |

| 0.15*108.25*20.15 | 20.15 | 108.25 | 12.65*12.65 | 12.6 | 11 | √ | ||

| 0.15*108.1*20.25(13.5*13.5) | 20.25 | 108.1 | 13.5*13.5 | 13.7 | 12 | √ | ||

| 7P 18650 Nickel strip | 0.15*121*19(12*12) | 19 | 121 | 12*12 | 11.5 | 10 | √ | |

| 0.15*128.4*20.15(12.65*12.65) | 20.15 | 128.4 | 12.65*12.65 | 10.7 | 9.4 | √ | ||

| 0.15*128.3*20.25(13.5*13.5) | 20.25 | 128.3 | 13.5*13.5 | 11.6 | 10.2 | √ | ||

| 8P 18650 Nickel strip | 0.15*140*19(12*12) | 19 | 140 | 12*12 | 10 | 8.7 | √ | |

For more details, pls directly contact us.

Other relevant knowledge points:

Classification society regulations: Ship manufacturing needs to comply with specific classification society regulations, such as the regulations of the International Maritime Organization (IMO) and the requirements of classification societies (such as classification societies DNV GL, LR, ABS, etc.). Selecting the appropriate material requires consideration of these specifications and requirements.

Ship Corrosion Protection: In addition to material selection, ship corrosion protection is also an important consideration. Common corrosion protection measures include coatings, anti-corrosion coatings and cathodic protection.

Sustainability of ship materials: As the requirements for sustainability and environmental friendliness continue to increase, choosing sustainable ship materials has become an important trend.

Q&A:

What material is pure nickel strip made of?

Pure nickel strip is a metal strip made of high-purity nickel.

What are the applications of pure nickel tape in the electronics industry?

Pure nickel tape is widely used in the electronics industry in resistors, connectors, relays, conductive materials and heat dissipation materials.

What are the main characteristics of pure nickel strip?

The main characteristics of pure nickel strip include excellent electrical conductivity, stable resistivity, good plasticity, weldability and corrosion resistance.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China