0

0

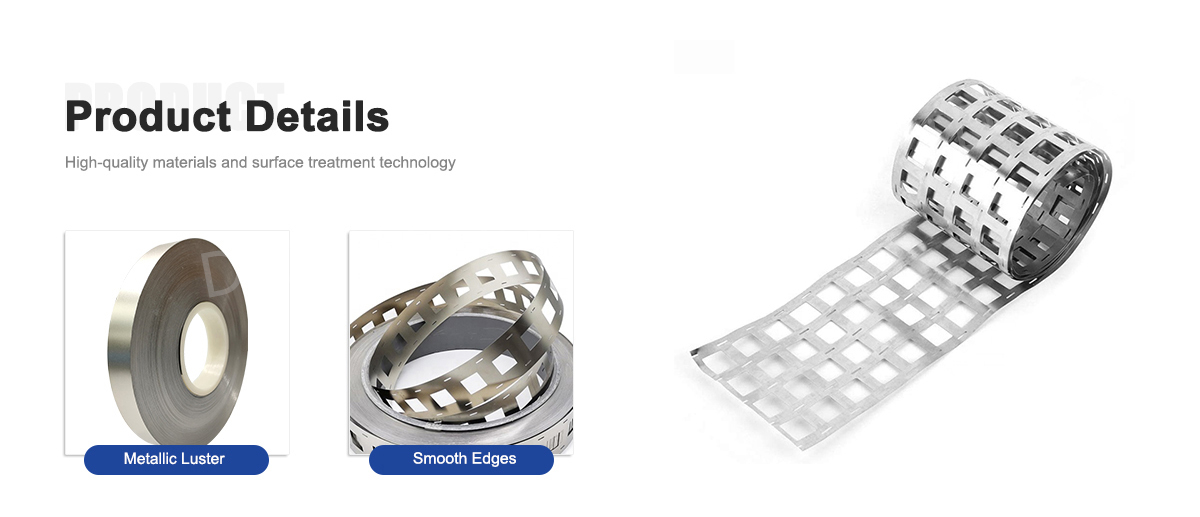

Products Description

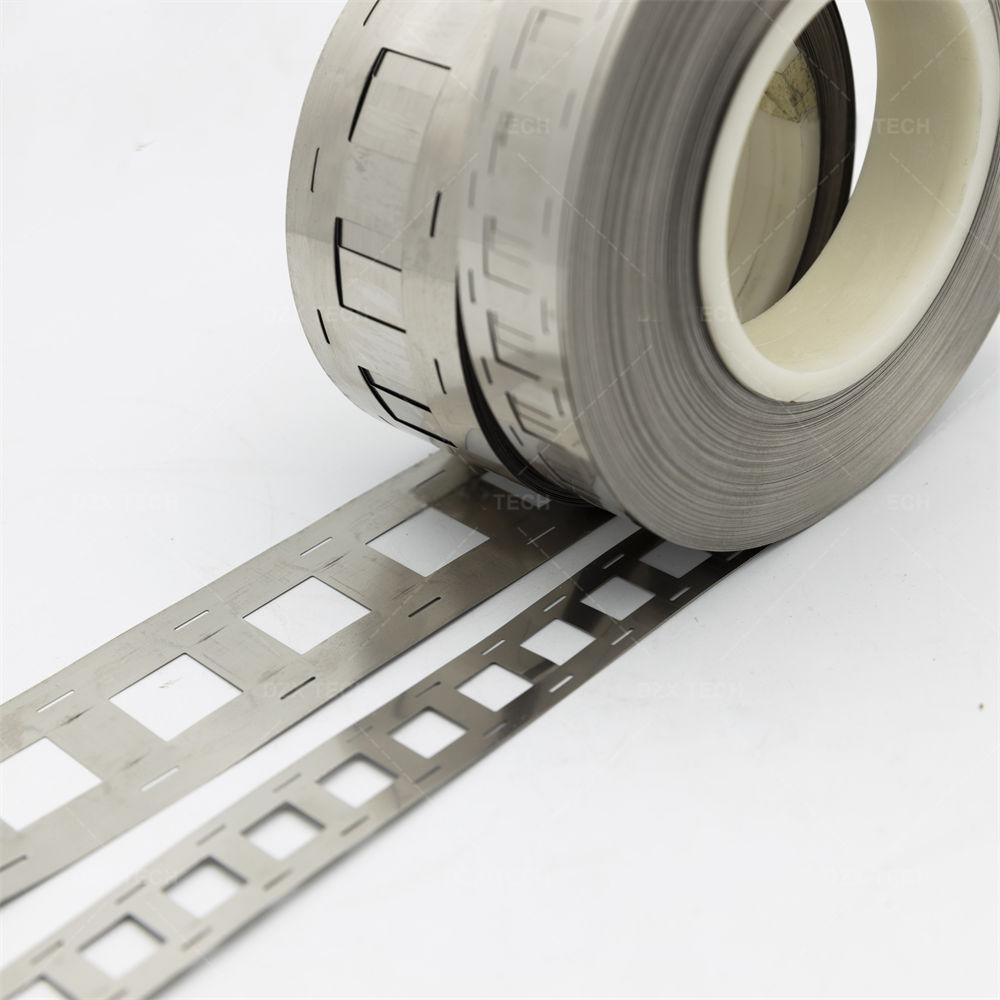

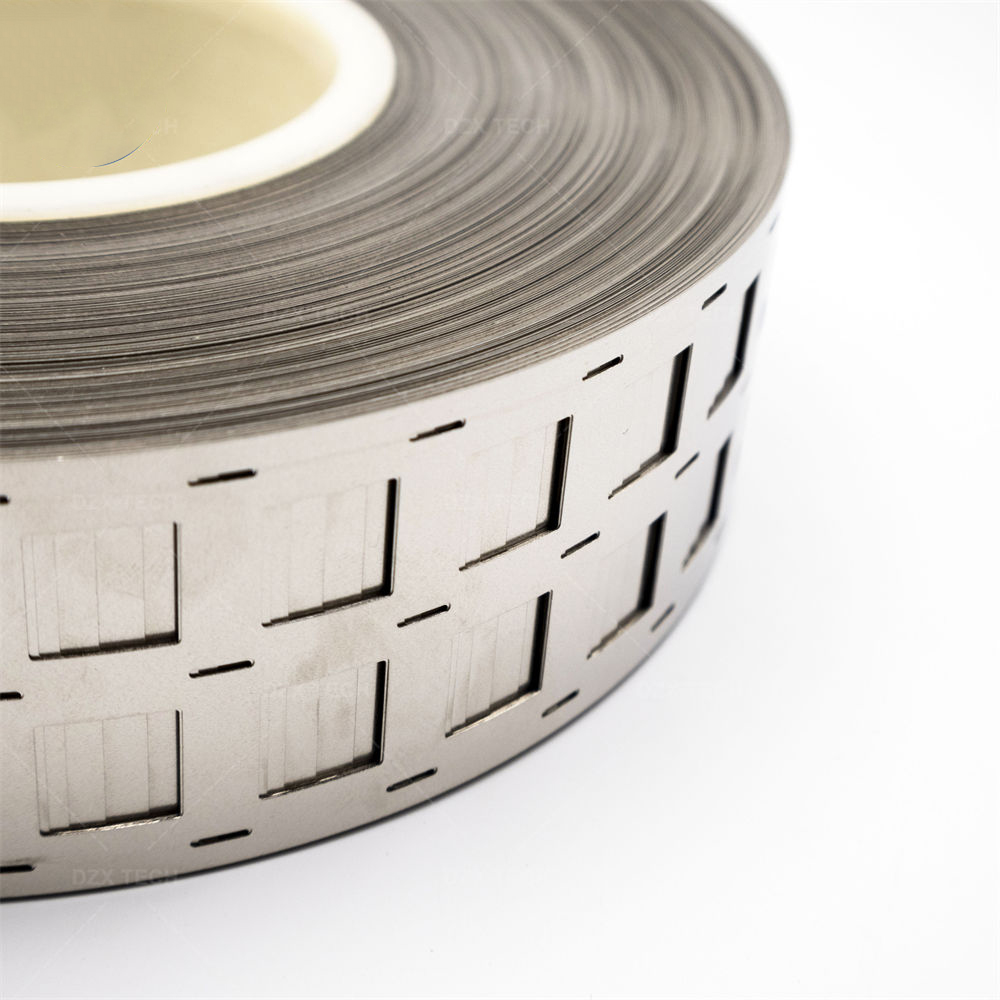

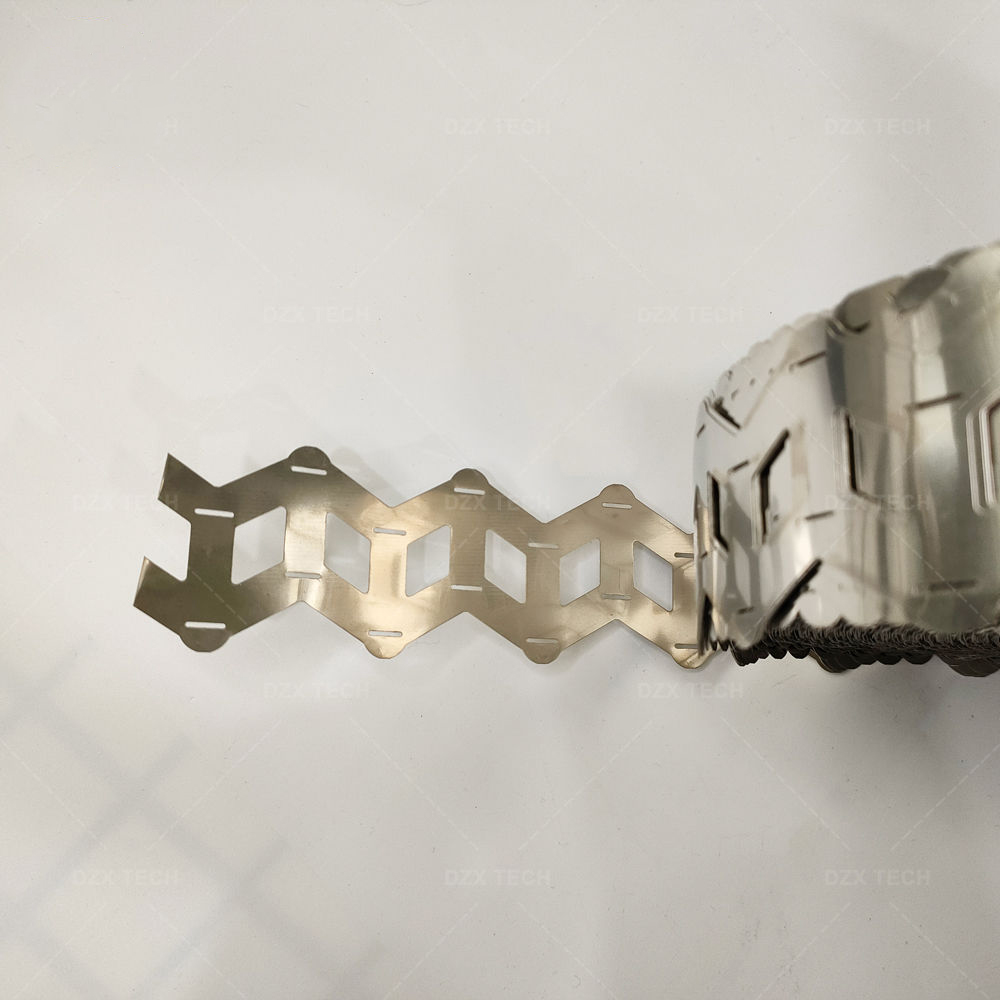

1P 2P 3P 4P 5P 6P pure nickel strip for 18650 28650 32650 lithium battery pack spot weld

Pure nickel ribbon has a wide range of applications in battery manufacturing. Due to its excellent electrical conductivity and corrosion resistance, pure nickel ribbon is widely used in manufacturing various types of batteries, such as lithium-ion batteries, nickel-metal hydride batteries, and nickel-cadmium batteries. Pure nickel tape plays a key role in the positive electrode, negative electrode and current collector of the battery. It can provide stable conductivity performance and resist corrosion and chemical reactions inside the battery, ensuring efficient operation and long life of the battery. The application of pure nickel ribbon provides battery manufacturers with high-quality, high-performance material solutions and promotes the development of electric vehicles, portable electronic devices and renewable energy storage.

Features

Electrical conductivity: Pure nickel tape has good electrical conductivity and can effectively conduct electric current.

Corrosion resistance: Pure nickel strips have good corrosion resistance against acidic and alkaline electrolytes in batteries.

Plasticity: Pure nickel strips have good plasticity and can be easily bent and shaped to adapt to the complex shape of the battery.

Advantage:

Excellent electrode material: Pure nickel ribbon can be used as an electrode material for batteries, with good electrical conductivity and chemical stability, helping to improve battery performance and cycle life.

Corrosion Resistance: Pure nickel strips resist corrosion in batteries, extending the life of the battery.

Strong plasticity: Pure nickel strips can be bent, folded and shaped according to the design requirements of the battery, adapting to the needs of various battery structures and sizes.

Functions / Applications

Lithium-ion batteries: Pure nickel strips can be used to make electrode materials for lithium-ion batteries, serving as current collectors for the positive or negative electrodes. Its high electrical conductivity and corrosion resistance help improve the performance and cycle life of lithium-ion batteries.

Nickel-metal hydride batteries: Pure nickel ribbons can also be used as cathode materials for nickel-metal hydride batteries, helping to improve the energy density and cycle life of the battery.

Fuel cells: Pure nickel ribbons can be used as electrode materials in fuel cells, helping to improve the electrochemical performance and stability of fuel cells.

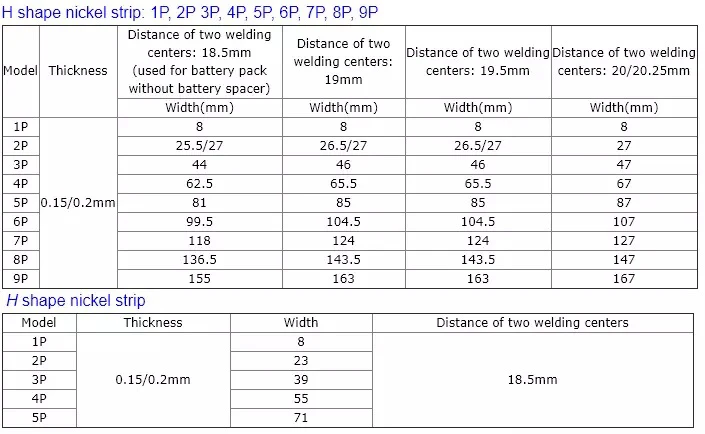

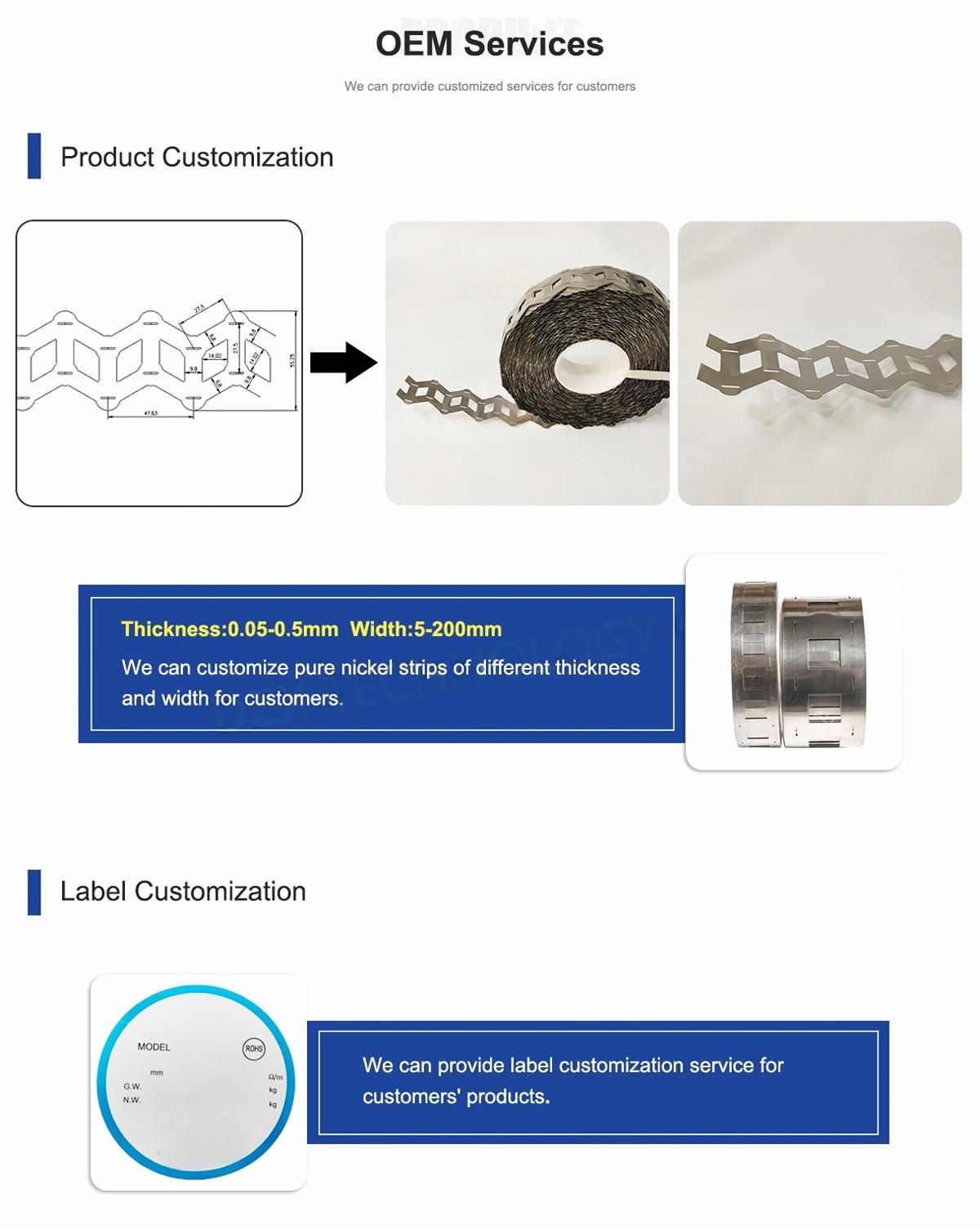

Dimension

The thickness and dimensions can be met what customers required.

Specification

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

| Type | Dimension(mm) | Cell Spacing:(mm) | Width | Dimension of the Square hole (mm) | Nickel Plated Steel Strip | Pure Nickel | Type of Battery Pack | |

| Length for per kg (m) | with holder | without holder | ||||||

| 1P 18650 Nickel strip | 0.15*7*18.4 | 18.4 | 7 | 一 | 128.3 | 112.6 | √ | |

| 0.15*7*19 | 19 | 一 | 127.9 | 112.1 | √ | |||

| 0.15*7*19.5 | 19.5 | 一 | √ | |||||

| 0.15*7*20.25 | 20.25 | 一 | 127.6 | 111.9 | √ | |||

| 2P 18650 Nickel strip | 0.15*26*19(13.5*13.5) | 19 | 26 | 12*12 | 47.2 | 41.4 | √ | |

| 0.15*27*19.5(12*14.5) | 19.5 | 27 | 12*14.5 | 48.9 | 42.9 | √ | ||

| 0.15*27*19.75(12.5*12.5) | 19.75 | 12.5*12.5 | 47 | 41.2 | √ | |||

| 0.15*27*20.25(13.5*13.5) | 20.25 | 13.5*13.5 | 48.9 | 42.9 | √ | |||

| 2P 18650 Nickel strip | 0.15*25.5*18.4(11*12.5) | 18.4 | 25.5 | 11*12.5 | 48.9 | 42.9 | √ | |

| Dislocation 2P 18650 Nickel strip | 0.15*25.5*18.4(8*9.5) | 18.4 | 8*9.5 | 41.1 | 36.1 | √ | ||

| Dislocation 2P 18650 Nickel strip | 0.15*25.5*19.5(8*9.5) | 19.5 | 8*9.5 | 38.6 | 33.8 | √ | ||

| 3P 18650 Nickel strip | 0.15*44.5*18.4(11*12.5) | 18.4 | 44.5 | 11*12.5 | 27.4 | 24 | √ | |

| 0.15*45*19(12*12) | 19 | 45 | 12*12 | 29.1 | 25.5 | √ | ||

| 0.15*47.5*20.15(12.65*12.65) | 20.15 | 47.5 | 12.6.5*12.65 | 27.4 | 24 | √ | ||

| 0.15*47.5*20.25(13.5*13.5) | 20.25 | 13.5*13.5 | 29.4 | 25.7 | √ | |||

| 4P 18650 Nickel strip | 0.15*63*18.5 (11*12.5) | 18.5 | 63 | 11*12.5 | 21.6 | 18.9 | √ | |

| 0.15*64*19(12*12) | 19 | 64 | 12*12 | 21 | 18.4 | √ | ||

| 0.15*67.95*20.15(12.65*12.65) | 20.15 | 67.95 | 12.65*12.65 | 19.6 | 17.2 | √ | ||

| 0.15*67.7*20.25(13.5*13.5) | 20.25 | 67 | 13.5*13.5 | 21.3 | 18.7 | √ | ||

| 5P 18650 Nickel strip | 0.15*83*19(12*12) | 19 | 83 | 12*12 | 16.4 | 14.4 | √ | |

| 0.15*88.1*20.15(12.65*12.65) | 20.15 | 88.1 | 12.65*12.65 | 19.7 | 17.3 | √ | ||

| 0.15*87.9*20.25(13.5*13.5) | 20.25 | 87.9 | 13.5*13.5 | 16.7 | 14.6 | √ | ||

| 6P 18650 Nickel strip | 0.15*102*19(12*12) | 19 | 102 | 12*12 | 13.5 | 11.9 | √ | |

| 0.15*108.25*20.15 | 20.15 | 108.25 | 12.65*12.65 | 12.6 | 11 | √ | ||

| 0.15*108.1*20.25(13.5*13.5) | 20.25 | 108.1 | 13.5*13.5 | 13.7 | 12 | √ | ||

| 7P 18650 Nickel strip | 0.15*121*19(12*12) | 19 | 121 | 12*12 | 11.5 | 10 | √ | |

| 0.15*128.4*20.15(12.65*12.65) | 20.15 | 128.4 | 12.65*12.65 | 10.7 | 9.4 | √ | ||

| 0.15*128.3*20.25(13.5*13.5) | 20.25 | 128.3 | 13.5*13.5 | 11.6 | 10.2 | √ | ||

| 8P 18650 Nickel strip | 0.15*140*19(12*12) | 19 | 140 | 12*12 | 10 | 8.7 | √ | |

For more details, pls directly contact us.

Other relevant knowledge points:

Battery manufacturing process: Battery manufacturing involves multiple process steps, including electrode preparation, electrolyte injection, packaging and testing. Proper material selection is critical to improving battery performance and reliability.

Battery performance indicators: Indicators for evaluating battery performance include energy density, cycle life, discharge platform, internal resistance, etc. Material selection is critical to achieving excellent battery performance.

New battery technology: In addition to traditional lithium-ion batteries and nickel-metal hydride batteries, there are other new battery technologies, such as solid-state batteries, lithium-sulfur batteries, and sodium-ion batteries. These new battery technologies may have different material selection and performance requirements.

Q&A:

What are the main characteristics of pure nickel strip?

The main characteristics of pure nickel strip include excellent electrical conductivity, stable resistivity, good plasticity, weldability and corrosion resistance.

How to make pure nickel belt?

Pure nickel strip can be manufactured through different processing methods, including rolling, drawing and welding.

What is the role of pure nickel tape in connectors?

Pure nickel strips are used as contact material in connectors, ensuring stable current transmission and reliable connections.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China