0

0

Products Description

1P 2P 3P 4P 5P 6P pure nickel strip for 18650 28650 32650 lithium battery pack spot weld

Pure nickel belt has a wide range of applications in the chemical industry. Due to its excellent corrosion resistance, pure nickel strip is widely used in the manufacture of critical components such as chemical equipment, petroleum processing units and nuclear power plant parts. In harsh chemical media environments, pure nickel belts can withstand a variety of corrosion, ensuring long-term reliable operation of equipment. It plays an important role in chemical processes, providing high-performance, corrosion-resistant material solutions to the chemical industry. Whether in key equipment such as chemical production units, storage tanks, pipelines or reactors, pure nickel belts can exert their excellent performance and provide reliable support for the safety, reliability and durability of the chemical industry.

Features

Corrosion resistance: Pure nickel belt has excellent corrosion resistance and can resist the erosion of a variety of corrosive media such as acids, alkalis, and salts, which allows it to withstand harsh working environments in the chemical industry.

Thermal stability: Pure nickel belt has good thermal stability, can maintain its mechanical properties and chemical stability at high temperatures, and is not easy to deform or crack.

Low magnetism: Pure nickel tape has low magnetic permeability and is not sensitive to magnetic fields. It is suitable for some chemical applications that require high magnetic interference.

Advantage:

Corrosion resistance: Pure nickel belts perform well in corrosive media such as strong acids and alkalis. They can resist the erosion of corrosive gases, liquids and corrosive solutions, ensuring the long-term stable operation of chemical equipment.

High-temperature oxidation resistance: Pure nickel strips can resist oxidation and thermal corrosion in high-temperature environments, and are suitable for refractory materials in high-temperature reactors, furnace tubes and other equipment.

Good processability: Pure nickel strips are easy to cold and hot process, and can be formed into various shapes and sizes to meet the complex needs of chemical equipment.

Functions / Applications

Chemical containers and equipment: Pure nickel strips can be used to manufacture parts and lining materials for chemical containers, reactors, heat exchangers, storage tanks and other chemical equipment to provide excellent corrosion resistance and thermal stability.

Chemical pipelines: Pure nickel belts can be used to manufacture chemical pipelines and fittings to ensure the safety and stability of the transportation of chemical media.

Corrosive media treatment: Pure nickel belts can be used to manufacture equipment in contact with corrosive media, such as acid and alkali washing equipment, wastewater treatment equipment, etc., to provide corrosion resistance and long life.

Catalyst carrier: Pure nickel tape can be used as a carrier material in catalyst preparation to provide stability at high temperatures and activity for catalytic reactions.

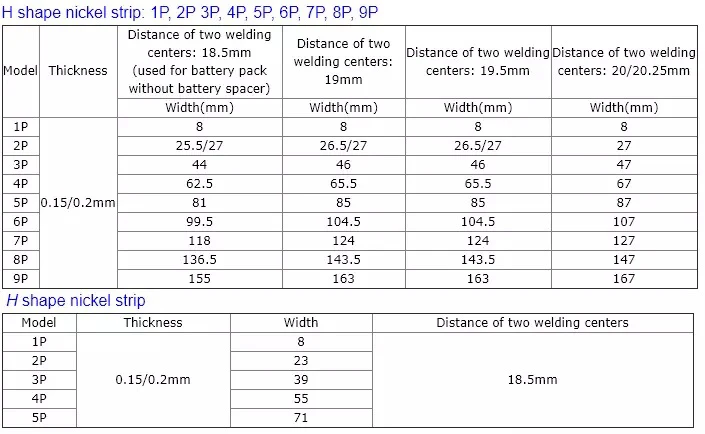

Dimension

The thickness and dimensions can be met what customers required.

Specification

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

| Type | Dimension(mm) | Cell Spacing:(mm) | Width | Dimension of the Square hole (mm) | Nickel Plated Steel Strip | Pure Nickel | Type of Battery Pack | |

| Length for per kg (m) | with holder | without holder | ||||||

| 1P 18650 Nickel strip | 0.15*7*18.4 | 18.4 | 7 | 一 | 128.3 | 112.6 | √ | |

| 0.15*7*19 | 19 | 一 | 127.9 | 112.1 | √ | |||

| 0.15*7*19.5 | 19.5 | 一 | √ | |||||

| 0.15*7*20.25 | 20.25 | 一 | 127.6 | 111.9 | √ | |||

| 2P 18650 Nickel strip | 0.15*26*19(13.5*13.5) | 19 | 26 | 12*12 | 47.2 | 41.4 | √ | |

| 0.15*27*19.5(12*14.5) | 19.5 | 27 | 12*14.5 | 48.9 | 42.9 | √ | ||

| 0.15*27*19.75(12.5*12.5) | 19.75 | 12.5*12.5 | 47 | 41.2 | √ | |||

| 0.15*27*20.25(13.5*13.5) | 20.25 | 13.5*13.5 | 48.9 | 42.9 | √ | |||

| 2P 18650 Nickel strip | 0.15*25.5*18.4(11*12.5) | 18.4 | 25.5 | 11*12.5 | 48.9 | 42.9 | √ | |

| Dislocation 2P 18650 Nickel strip | 0.15*25.5*18.4(8*9.5) | 18.4 | 8*9.5 | 41.1 | 36.1 | √ | ||

| Dislocation 2P 18650 Nickel strip | 0.15*25.5*19.5(8*9.5) | 19.5 | 8*9.5 | 38.6 | 33.8 | √ | ||

| 3P 18650 Nickel strip | 0.15*44.5*18.4(11*12.5) | 18.4 | 44.5 | 11*12.5 | 27.4 | 24 | √ | |

| 0.15*45*19(12*12) | 19 | 45 | 12*12 | 29.1 | 25.5 | √ | ||

| 0.15*47.5*20.15(12.65*12.65) | 20.15 | 47.5 | 12.6.5*12.65 | 27.4 | 24 | √ | ||

| 0.15*47.5*20.25(13.5*13.5) | 20.25 | 13.5*13.5 | 29.4 | 25.7 | √ | |||

| 4P 18650 Nickel strip | 0.15*63*18.5 (11*12.5) | 18.5 | 63 | 11*12.5 | 21.6 | 18.9 | √ | |

| 0.15*64*19(12*12) | 19 | 64 | 12*12 | 21 | 18.4 | √ | ||

| 0.15*67.95*20.15(12.65*12.65) | 20.15 | 67.95 | 12.65*12.65 | 19.6 | 17.2 | √ | ||

| 0.15*67.7*20.25(13.5*13.5) | 20.25 | 67 | 13.5*13.5 | 21.3 | 18.7 | √ | ||

| 5P 18650 Nickel strip | 0.15*83*19(12*12) | 19 | 83 | 12*12 | 16.4 | 14.4 | √ | |

| 0.15*88.1*20.15(12.65*12.65) | 20.15 | 88.1 | 12.65*12.65 | 19.7 | 17.3 | √ | ||

| 0.15*87.9*20.25(13.5*13.5) | 20.25 | 87.9 | 13.5*13.5 | 16.7 | 14.6 | √ | ||

| 6P 18650 Nickel strip | 0.15*102*19(12*12) | 19 | 102 | 12*12 | 13.5 | 11.9 | √ | |

| 0.15*108.25*20.15 | 20.15 | 108.25 | 12.65*12.65 | 12.6 | 11 | √ | ||

| 0.15*108.1*20.25(13.5*13.5) | 20.25 | 108.1 | 13.5*13.5 | 13.7 | 12 | √ | ||

| 7P 18650 Nickel strip | 0.15*121*19(12*12) | 19 | 121 | 12*12 | 11.5 | 10 | √ | |

| 0.15*128.4*20.15(12.65*12.65) | 20.15 | 128.4 | 12.65*12.65 | 10.7 | 9.4 | √ | ||

| 0.15*128.3*20.25(13.5*13.5) | 20.25 | 128.3 | 13.5*13.5 | 11.6 | 10.2 | √ | ||

| 8P 18650 Nickel strip | 0.15*140*19(12*12) | 19 | 140 | 12*12 | 10 | 8.7 | √ | |

For more details, pls directly contact us.

Other relevant knowledge points:

Material selection in the chemical industry: In the chemical industry, material selection is very important and needs to be evaluated and selected based on factors such as specific media, temperature, pressure, and process requirements. In addition to pure nickel strips, other corrosion-resistant materials such as 316 stainless steel, titanium and Hastelloy are also commonly used in chemical equipment manufacturing.

Applications of nickel alloys: In addition to pure nickel strips, nickel-based alloys are also widely used in the chemical industry. Nickel-based alloys are composed of nickel and other alloy elements (such as chromium, molybdenum, titanium, etc.). They have higher corrosion resistance, high-temperature strength and heat resistance, and are suitable for more harsh chemical environments.

Q&A:

What is the electrical conductivity of pure nickel tape?

Pure nickel tape has excellent electrical conductivity and can effectively conduct electric current.

What environmental conditions are pure nickel belts suitable for?

Pure nickel belt has good corrosion resistance and can resist corrosion and oxidation caused by humidity, acid and alkali and other environmental conditions.

How do pure nickel strips connect to other materials?

Pure nickel strips can be reliably connected to other materials through welding and other methods.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China