0

0

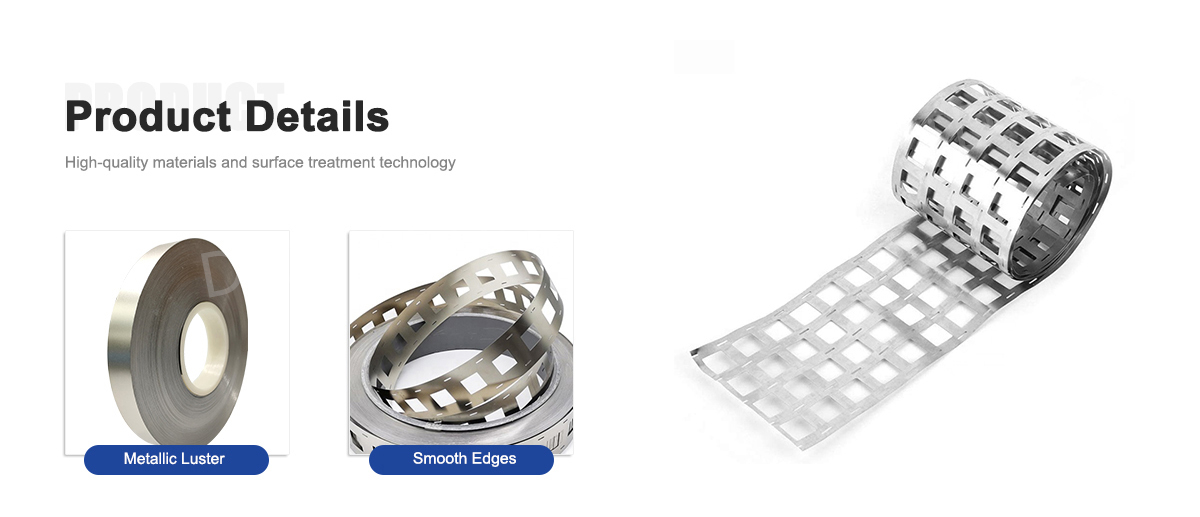

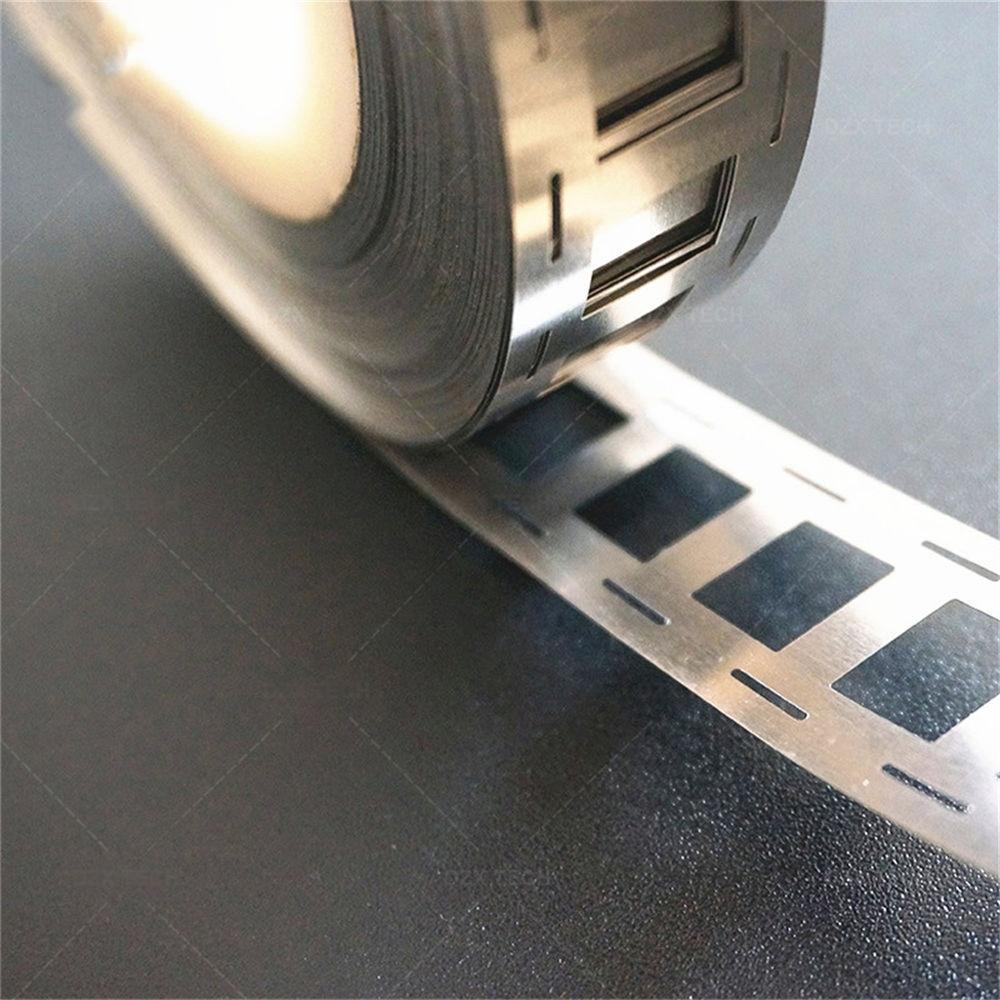

Products Description

1P 2P 3P 4P 5P 6P pure nickel strip for 18650 28650 32650 lithium battery pack spot weld

Pure nickel belt plays an important role in the aerospace field. As a high-temperature, corrosion-resistant and high-strength material, pure nickel strips are widely used in manufacturing key components of aerospace engines, such as turbine engine blades and combustion chamber parts. Its excellent high-temperature stability and corrosion resistance enable it to maintain stable performance in extreme environments and ensure reliable operation of aircraft. Pure nickel strips also play an important role in aerospace structures, pipes and valves, providing key material solutions to the aerospace industry.

Features

Corrosion resistance: Pure nickel belt has excellent corrosion resistance and can resist the erosion of corrosive media such as oxidation, acid and alkali, which makes its use in harsh environments feasible.

High temperature strength: Pure nickel belt has excellent high temperature strength, can maintain its mechanical properties in high temperature environment, and is not easy to deform or break.

Low thermal expansion coefficient: The thermal expansion coefficient of pure nickel tape is low, which allows it to maintain dimensional stability under large temperature changes and reduce problems caused by thermal expansion and contraction.

Magnetic properties: Pure nickel tape has high magnetic permeability and magnetic saturation induction intensity, giving it certain advantages in electromagnetic applications.

Advantage:

Lightweight: Pure nickel tape has a low density and is relatively light, which can achieve lightweight structures and improve load capacity and fuel efficiency in the aerospace field.

High strength: Pure nickel strip has high tensile strength and yield strength, and can withstand high stress and load in the aerospace field, providing structural strength and safety.

High temperature resistance: Pure nickel belts can be used in high-temperature environments for a long time and can withstand stresses such as oxidation and thermal expansion at high temperatures. They are suitable for high-temperature components such as aerospace engines and gas turbines.

Good processability: Pure nickel strips are easy to process into various shapes and sizes, and can be formed and processed through cold rolling, hot rolling, drawing and other processes.

Functions / Applications

Aeroengine: Pure nickel belts are widely used in high-temperature parts such as gas turbine blades, turbine disks, and combustion chambers of aeroengines to provide high-temperature strength and corrosion resistance.

Spacecraft structure: Pure nickel strips can be used in spacecraft structural parts, fuel tanks, navigation systems, etc. to provide lightweight, high strength and good corrosion resistance.

Gas turbine: Pure nickel belts are widely used in gas turbine blades, discs, combustion chambers and other components to meet high temperature, high stress and corrosion resistance requirements.

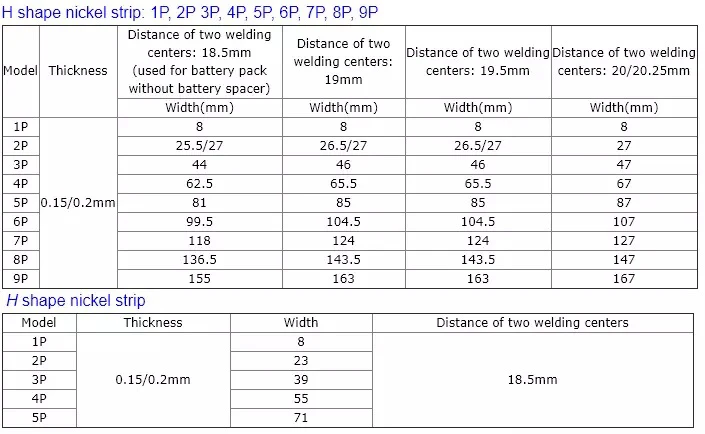

Dimension

The thickness and dimensions can be met what customers required.

Specification

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

| Type | Dimension(mm) | Cell Spacing:(mm) | Width | Dimension of the Square hole (mm) | Nickel Plated Steel Strip | Pure Nickel | Type of Battery Pack | |

| Length for per kg (m) | with holder | without holder | ||||||

| 1P 18650 Nickel strip | 0.15*7*18.4 | 18.4 | 7 | 一 | 128.3 | 112.6 | √ | |

| 0.15*7*19 | 19 | 一 | 127.9 | 112.1 | √ | |||

| 0.15*7*19.5 | 19.5 | 一 | √ | |||||

| 0.15*7*20.25 | 20.25 | 一 | 127.6 | 111.9 | √ | |||

| 2P 18650 Nickel strip | 0.15*26*19(13.5*13.5) | 19 | 26 | 12*12 | 47.2 | 41.4 | √ | |

| 0.15*27*19.5(12*14.5) | 19.5 | 27 | 12*14.5 | 48.9 | 42.9 | √ | ||

| 0.15*27*19.75(12.5*12.5) | 19.75 | 12.5*12.5 | 47 | 41.2 | √ | |||

| 0.15*27*20.25(13.5*13.5) | 20.25 | 13.5*13.5 | 48.9 | 42.9 | √ | |||

| 2P 18650 Nickel strip | 0.15*25.5*18.4(11*12.5) | 18.4 | 25.5 | 11*12.5 | 48.9 | 42.9 | √ | |

| Dislocation 2P 18650 Nickel strip | 0.15*25.5*18.4(8*9.5) | 18.4 | 8*9.5 | 41.1 | 36.1 | √ | ||

| Dislocation 2P 18650 Nickel strip | 0.15*25.5*19.5(8*9.5) | 19.5 | 8*9.5 | 38.6 | 33.8 | √ | ||

| 3P 18650 Nickel strip | 0.15*44.5*18.4(11*12.5) | 18.4 | 44.5 | 11*12.5 | 27.4 | 24 | √ | |

| 0.15*45*19(12*12) | 19 | 45 | 12*12 | 29.1 | 25.5 | √ | ||

| 0.15*47.5*20.15(12.65*12.65) | 20.15 | 47.5 | 12.6.5*12.65 | 27.4 | 24 | √ | ||

| 0.15*47.5*20.25(13.5*13.5) | 20.25 | 13.5*13.5 | 29.4 | 25.7 | √ | |||

| 4P 18650 Nickel strip | 0.15*63*18.5 (11*12.5) | 18.5 | 63 | 11*12.5 | 21.6 | 18.9 | √ | |

| 0.15*64*19(12*12) | 19 | 64 | 12*12 | 21 | 18.4 | √ | ||

| 0.15*67.95*20.15(12.65*12.65) | 20.15 | 67.95 | 12.65*12.65 | 19.6 | 17.2 | √ | ||

| 0.15*67.7*20.25(13.5*13.5) | 20.25 | 67 | 13.5*13.5 | 21.3 | 18.7 | √ | ||

| 5P 18650 Nickel strip | 0.15*83*19(12*12) | 19 | 83 | 12*12 | 16.4 | 14.4 | √ | |

| 0.15*88.1*20.15(12.65*12.65) | 20.15 | 88.1 | 12.65*12.65 | 19.7 | 17.3 | √ | ||

| 0.15*87.9*20.25(13.5*13.5) | 20.25 | 87.9 | 13.5*13.5 | 16.7 | 14.6 | √ | ||

| 6P 18650 Nickel strip | 0.15*102*19(12*12) | 19 | 102 | 12*12 | 13.5 | 11.9 | √ | |

| 0.15*108.25*20.15 | 20.15 | 108.25 | 12.65*12.65 | 12.6 | 11 | √ | ||

| 0.15*108.1*20.25(13.5*13.5) | 20.25 | 108.1 | 13.5*13.5 | 13.7 | 12 | √ | ||

| 7P 18650 Nickel strip | 0.15*121*19(12*12) | 19 | 121 | 12*12 | 11.5 | 10 | √ | |

| 0.15*128.4*20.15(12.65*12.65) | 20.15 | 128.4 | 12.65*12.65 | 10.7 | 9.4 | √ | ||

| 0.15*128.3*20.25(13.5*13.5) | 20.25 | 128.3 | 13.5*13.5 | 11.6 | 10.2 | √ | ||

| 8P 18650 Nickel strip | 0.15*140*19(12*12) | 19 | 140 | 12*12 | 10 | 8.7 | √ | |

For more details, pls directly contact us.

Other relevant knowledge points:

Nickel-based alloys: In addition to pure nickel strips, another common type of material is nickel-based alloys. They are composed of nickel and other alloying elements (such as chromium, molybdenum, titanium, etc.) and have higher strength and heat resistance. Widely used in aerospace, petrochemical and other fields.

Properties of Nickel: Nickel is a transition metal with good corrosion resistance, electrical conductivity and magnetism. It has good plasticity and workability and can be shaped and processed through cold and hot processing.

Nickel's oxidation resistance: Nickel has good oxidation resistance and can form a dense oxide film to protect the substrate from oxidation and corrosion.

Thermal expansion coefficient of nickel: Pure nickel strip has a low thermal expansion coefficient of approximately 11×10^-6/°C, giving it excellent dimensional stability at high temperatures.

Magnetism of Nickel: Pure nickel strips have high magnetic permeability and magnetic saturation induction strength, and can be used in electromagnetic applications, such as sensors, inductors, etc.

Q&A:

What are the advantages of pure nickel belt?

The advantages of pure nickel tape include high precision and stability, reliable connection performance and good heat dissipation.

How to make pure nickel belt?

Pure nickel strip can be manufactured through different processing methods, including rolling, drawing and welding.

What are the common thickness ranges for pure nickel strip?

The thickness of pure nickel strip can be customized according to the requirements of the specific application, with common thicknesses typically ranging from a few microns to a few millimeters.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China