0

0

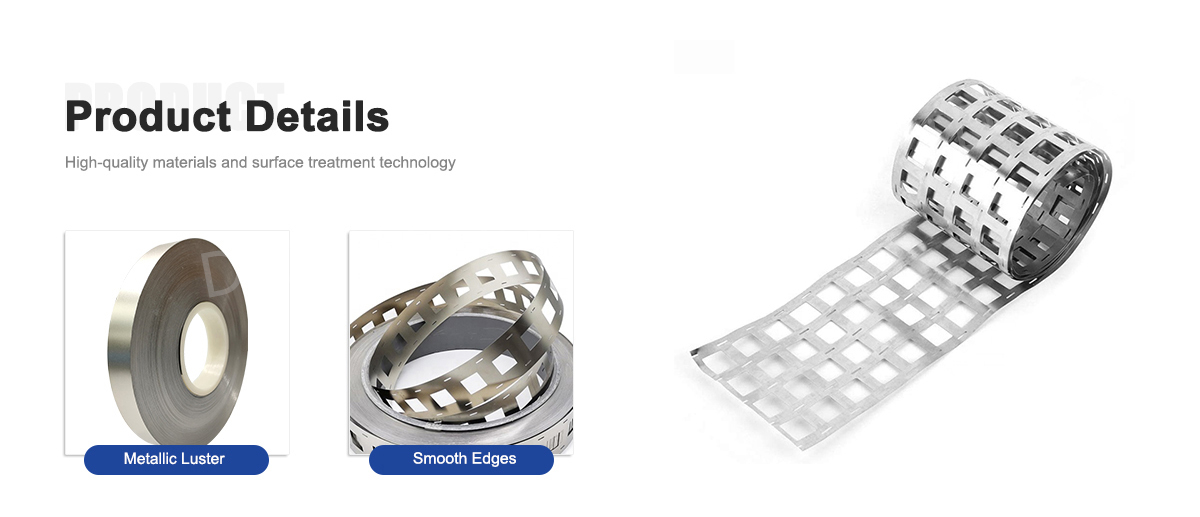

Products Description

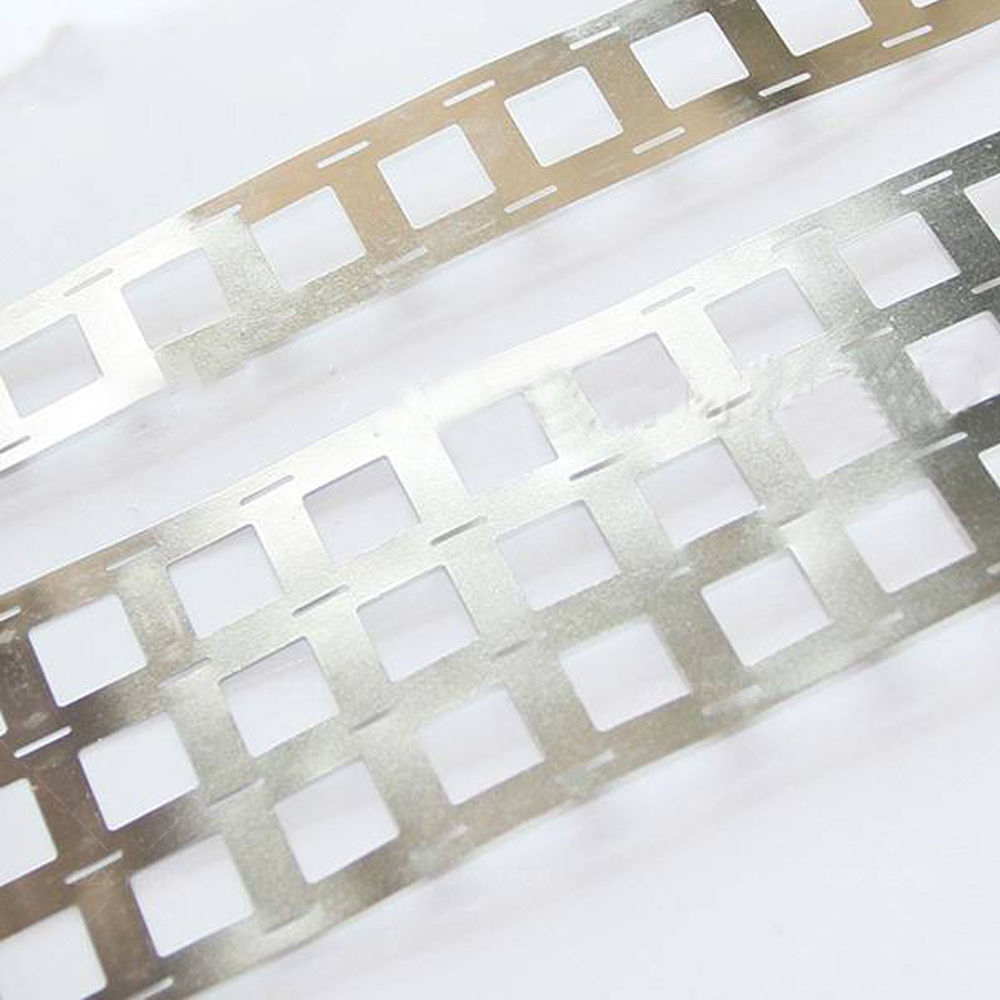

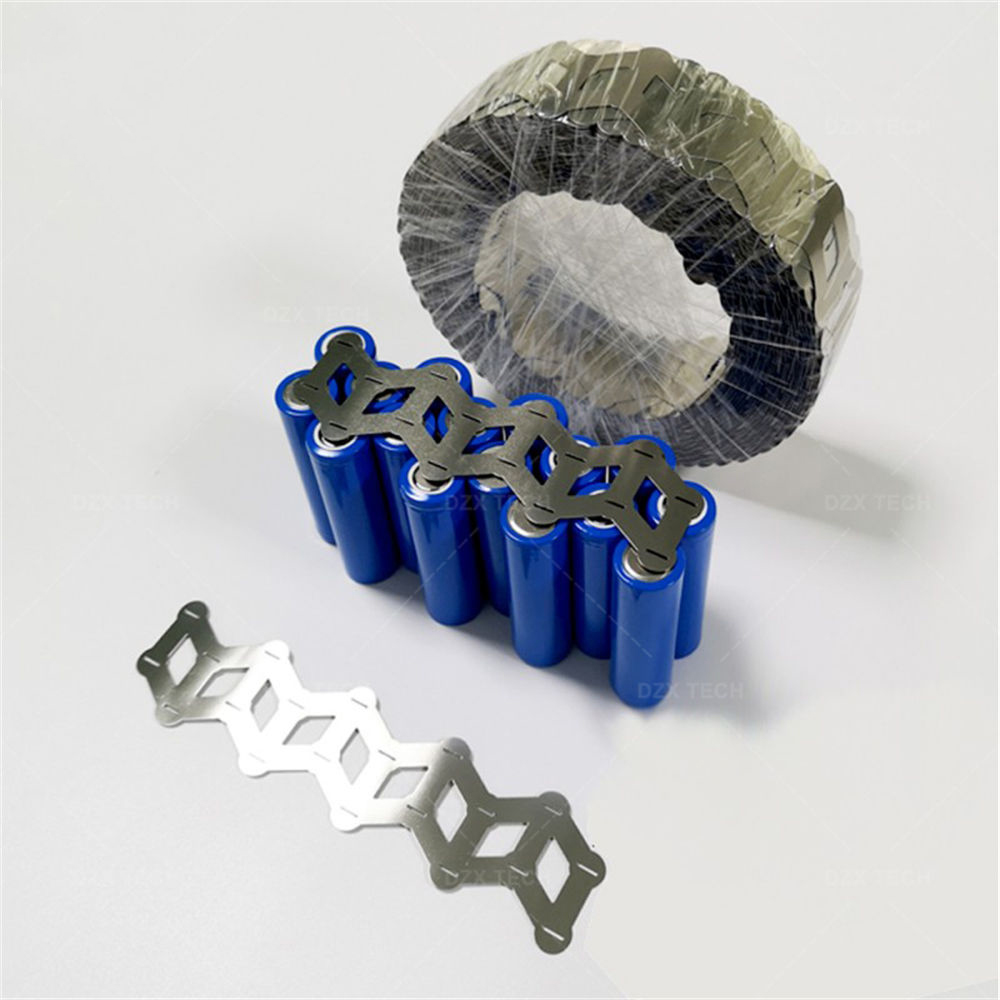

1P 2P 3P 4P 5P 6P pure nickel strip for 18650 28650 32650 lithium battery pack spot weld

Pure nickel strip plays an important role in the oil and gas industry. Due to its excellent corrosion resistance and high temperature stability, pure nickel tape is widely used in manufacturing oil and gas equipment, such as pipelines, valves, pumps and other key components. In harsh oil and gas environments, pure nickel strips can withstand corrosion and high temperatures, maintaining their performance and reliability, ensuring the safe operation of energy facilities. It can cope with various chemical media and pressure conditions, extend the service life of equipment, reduce the frequency of maintenance and replacement, and reduce operating costs. The application of pure nickel strips in the oil and gas industry provides reliable material solutions for the development and production of the industry, while also contributing to the sustainability of energy supply.

Features

Corrosion resistance: Pure nickel belt has excellent corrosion resistance and can resist corrosive media in oil and gas, including sulfide, acidic substances and corrosion under high temperature and high pressure conditions.

High temperature strength: Pure nickel belt has good high temperature strength and heat resistance, and can maintain its mechanical properties and chemical stability in high temperature and high pressure environments.

Oxidation resistance: Pure nickel belts can resist oxidation at high temperatures, prevent thermal oxidation reactions, and help extend the service life of equipment.

Advantage:

Corrosion resistance: Pure nickel belts have excellent corrosion resistance against corrosive media in oil and natural gas, and can operate stably for a long time in harsh working environments, reducing the frequency of equipment maintenance and replacement.

High-temperature oxidation resistance: Pure nickel belts have good oxidation resistance in high-temperature environments and can resist high-temperature oxidation and hot corrosion to ensure safe and stable operation of equipment.

Good processability: Pure nickel strips are easy to cold and hot process, and can be formed into various shapes and sizes to adapt to the complex needs of the oil and gas industry.

Functions / Applications

Oil well casing and pipes: Pure nickel strips can be used to manufacture oil well casing and pipes, which withstand the transportation and storage of oil and natural gas and have excellent corrosion resistance and high temperature strength.

Chemical processing equipment: Pure nickel strips can be used to manufacture chemical processing equipment, such as storage tanks, reactors and heat exchangers for corrosive media, to provide corrosion resistance and high temperature tolerance.

Catalyst manufacturing: Pure nickel ribbon is often used as a carrier material for catalysts in oil and gas processing to improve reaction efficiency and selectivity.

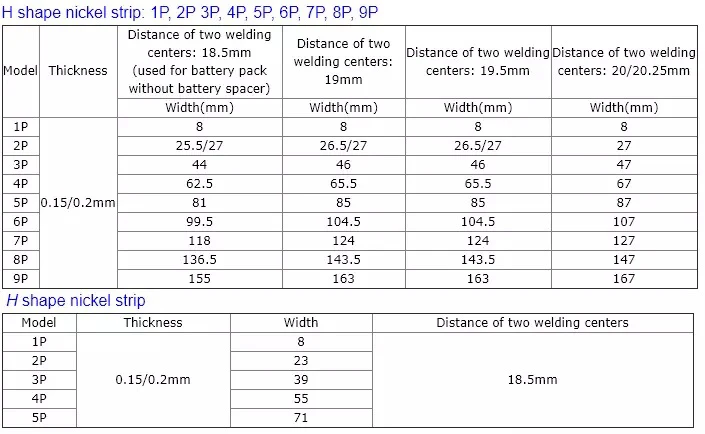

Dimension

The thickness and dimensions can be met what customers required.

Specification

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

| Type | Dimension(mm) | Cell Spacing:(mm) | Width | Dimension of the Square hole (mm) | Nickel Plated Steel Strip | Pure Nickel | Type of Battery Pack | |

| Length for per kg (m) | with holder | without holder | ||||||

| 1P 18650 Nickel strip | 0.15*7*18.4 | 18.4 | 7 | 一 | 128.3 | 112.6 | √ | |

| 0.15*7*19 | 19 | 一 | 127.9 | 112.1 | √ | |||

| 0.15*7*19.5 | 19.5 | 一 | √ | |||||

| 0.15*7*20.25 | 20.25 | 一 | 127.6 | 111.9 | √ | |||

| 2P 18650 Nickel strip | 0.15*26*19(13.5*13.5) | 19 | 26 | 12*12 | 47.2 | 41.4 | √ | |

| 0.15*27*19.5(12*14.5) | 19.5 | 27 | 12*14.5 | 48.9 | 42.9 | √ | ||

| 0.15*27*19.75(12.5*12.5) | 19.75 | 12.5*12.5 | 47 | 41.2 | √ | |||

| 0.15*27*20.25(13.5*13.5) | 20.25 | 13.5*13.5 | 48.9 | 42.9 | √ | |||

| 2P 18650 Nickel strip | 0.15*25.5*18.4(11*12.5) | 18.4 | 25.5 | 11*12.5 | 48.9 | 42.9 | √ | |

| Dislocation 2P 18650 Nickel strip | 0.15*25.5*18.4(8*9.5) | 18.4 | 8*9.5 | 41.1 | 36.1 | √ | ||

| Dislocation 2P 18650 Nickel strip | 0.15*25.5*19.5(8*9.5) | 19.5 | 8*9.5 | 38.6 | 33.8 | √ | ||

| 3P 18650 Nickel strip | 0.15*44.5*18.4(11*12.5) | 18.4 | 44.5 | 11*12.5 | 27.4 | 24 | √ | |

| 0.15*45*19(12*12) | 19 | 45 | 12*12 | 29.1 | 25.5 | √ | ||

| 0.15*47.5*20.15(12.65*12.65) | 20.15 | 47.5 | 12.6.5*12.65 | 27.4 | 24 | √ | ||

| 0.15*47.5*20.25(13.5*13.5) | 20.25 | 13.5*13.5 | 29.4 | 25.7 | √ | |||

| 4P 18650 Nickel strip | 0.15*63*18.5 (11*12.5) | 18.5 | 63 | 11*12.5 | 21.6 | 18.9 | √ | |

| 0.15*64*19(12*12) | 19 | 64 | 12*12 | 21 | 18.4 | √ | ||

| 0.15*67.95*20.15(12.65*12.65) | 20.15 | 67.95 | 12.65*12.65 | 19.6 | 17.2 | √ | ||

| 0.15*67.7*20.25(13.5*13.5) | 20.25 | 67 | 13.5*13.5 | 21.3 | 18.7 | √ | ||

| 5P 18650 Nickel strip | 0.15*83*19(12*12) | 19 | 83 | 12*12 | 16.4 | 14.4 | √ | |

| 0.15*88.1*20.15(12.65*12.65) | 20.15 | 88.1 | 12.65*12.65 | 19.7 | 17.3 | √ | ||

| 0.15*87.9*20.25(13.5*13.5) | 20.25 | 87.9 | 13.5*13.5 | 16.7 | 14.6 | √ | ||

| 6P 18650 Nickel strip | 0.15*102*19(12*12) | 19 | 102 | 12*12 | 13.5 | 11.9 | √ | |

| 0.15*108.25*20.15 | 20.15 | 108.25 | 12.65*12.65 | 12.6 | 11 | √ | ||

| 0.15*108.1*20.25(13.5*13.5) | 20.25 | 108.1 | 13.5*13.5 | 13.7 | 12 | √ | ||

| 7P 18650 Nickel strip | 0.15*121*19(12*12) | 19 | 121 | 12*12 | 11.5 | 10 | √ | |

| 0.15*128.4*20.15(12.65*12.65) | 20.15 | 128.4 | 12.65*12.65 | 10.7 | 9.4 | √ | ||

| 0.15*128.3*20.25(13.5*13.5) | 20.25 | 128.3 | 13.5*13.5 | 11.6 | 10.2 | √ | ||

| 8P 18650 Nickel strip | 0.15*140*19(12*12) | 19 | 140 | 12*12 | 10 | 8.7 | √ | |

For more details, pls directly contact us.

Other relevant knowledge points:

Applications of High Alloy Steel: In addition to pure nickel strip, high alloy steel is also widely used in the oil and gas industry. High alloy steel is a kind of steel containing a variety of alloy elements (such as nickel, chromium, molybdenum, etc.). It has excellent corrosion resistance and high temperature resistance and is suitable for marine environments, oil well equipment, pipelines and other fields.

Corrosion problems in oil and natural gas: There are many corrosion problems in oil and natural gas, including sulfide corrosion, acid corrosion and corrosion in high temperature and high pressure environments. Choosing the right materials can effectively reduce the damage caused by corrosion.

Applications of Nickel-based Alloys: In the oil and gas industry, nickel-based alloys are also widely used in the oil and gas industry. Nickel-based alloys are composed of nickel and other alloying elements (such as chromium, molybdenum, titanium, etc.) and have excellent corrosion resistance, high-temperature strength, and heat resistance. They are often used to manufacture oil well equipment, refining equipment, pipelines and valves under high temperature and pressure to cope with harsh working environments and requirements.

Q&A:

How is pure nickel tape used for heat dissipation in electronic equipment?

As a heat dissipation material, pure nickel strips can effectively conduct and disperse the heat generated by the equipment and maintain the stable operating temperature of the equipment.

How difficult is it to process pure nickel strip?

Since pure nickel strip has good plasticity and weldability, it is relatively easy to process.

Are the conductive properties of pure nickel tape affected by temperature?

The resistivity and conductive properties of pure nickel strips will be affected by temperature, but generally have a smaller temperature coefficient and maintain relatively stable performance.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China