0

0

Products Description

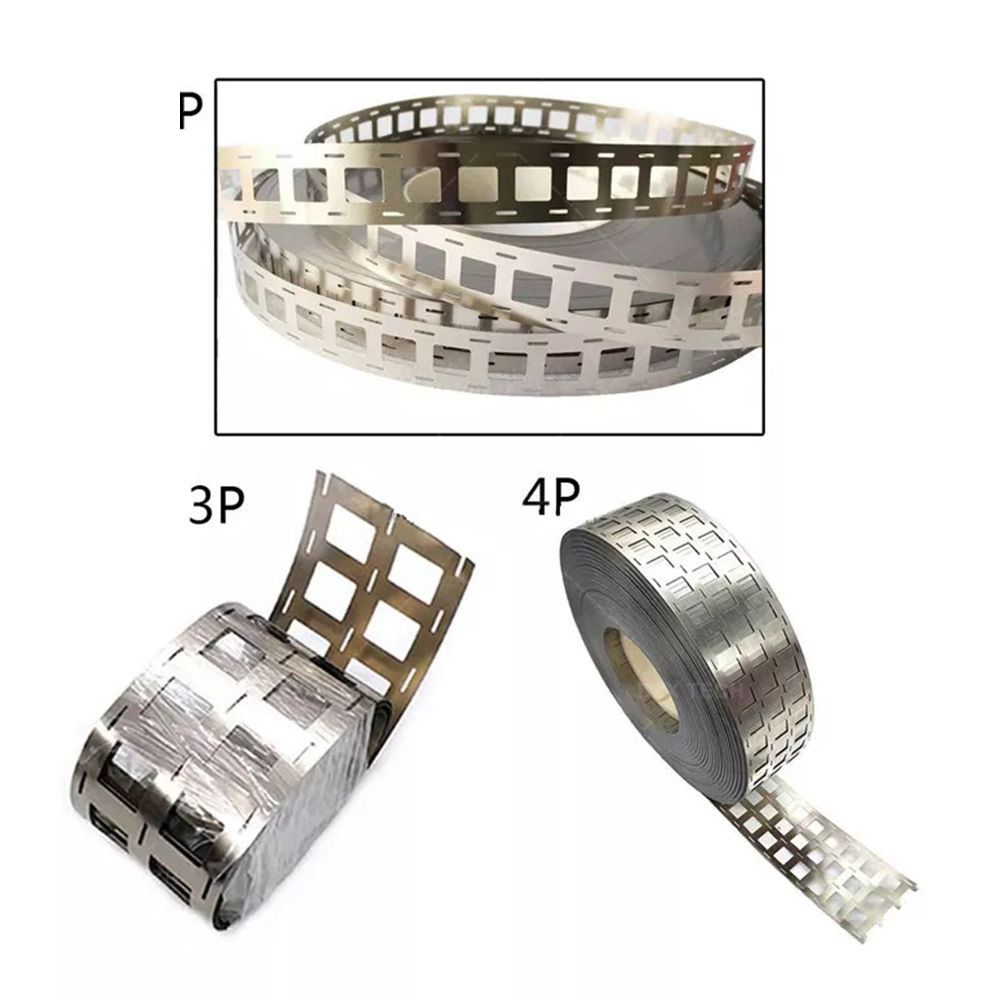

1P 2P 3P 4P 5P 6P pure nickel strip for 18650 28650 32650 lithium battery pack spot weld

Pure nickel strip is a strip product made of high-purity nickel material with excellent corrosion resistance, high temperature performance and electrical conductivity. It is widely used in the fields of electronics, aerospace, chemical, petroleum and nuclear industries, and is used to manufacture electronic components, high-temperature parts and chemical equipment. The excellent properties of pure nickel tape make it one of the key materials for functionality and reliability in many fields.

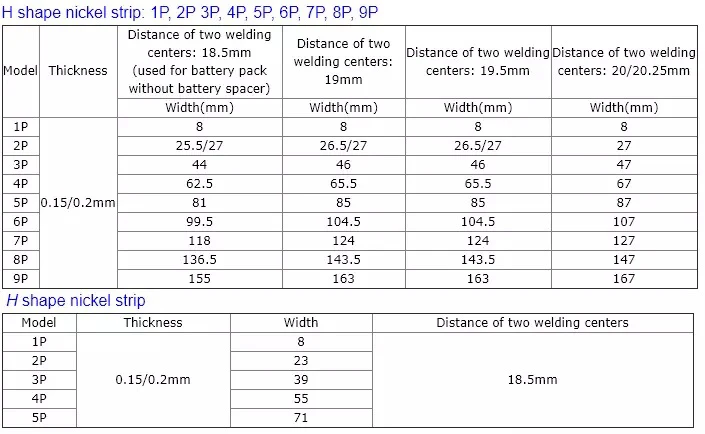

Dimension

The thickness and dimensions can be met what customers required.

Features

Corrosion resistance: Pure nickel belt has excellent corrosion resistance and can resist corrosion from various chemical media, making it suitable for applications in various harsh environments.

High temperature performance: Pure nickel strip has excellent high temperature stability and can maintain its performance and structural stability under extreme temperature conditions, making it an ideal choice for high temperature applications.

Conductive properties: Pure nickel tape has good electrical conductivity and can effectively conduct current, making it widely used in the electronic field to manufacture electronic components and conductive parts.

Mechanical properties: Pure nickel strips have high strength and excellent mechanical properties, can withstand complex stress and deformation, and have good plasticity and processability.

Specification

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

| Type | Dimension(mm) | Cell Spacing:(mm) | Width | Dimension of the Square hole (mm) | Nickel Plated Steel Strip | Pure Nickel | Type of Battery Pack | |

| Length for per kg (m) | with holder | without holder | ||||||

| 1P 18650 Nickel strip | 0.15*7*18.4 | 18.4 | 7 | 一 | 128.3 | 112.6 | √ | |

| 0.15*7*19 | 19 | 一 | 127.9 | 112.1 | √ | |||

| 0.15*7*19.5 | 19.5 | 一 | √ | |||||

| 0.15*7*20.25 | 20.25 | 一 | 127.6 | 111.9 | √ | |||

| 2P 18650 Nickel strip | 0.15*26*19(13.5*13.5) | 19 | 26 | 12*12 | 47.2 | 41.4 | √ | |

| 0.15*27*19.5(12*14.5) | 19.5 | 27 | 12*14.5 | 48.9 | 42.9 | √ | ||

| 0.15*27*19.75(12.5*12.5) | 19.75 | 12.5*12.5 | 47 | 41.2 | √ | |||

| 0.15*27*20.25(13.5*13.5) | 20.25 | 13.5*13.5 | 48.9 | 42.9 | √ | |||

| 2P 18650 Nickel strip | 0.15*25.5*18.4(11*12.5) | 18.4 | 25.5 | 11*12.5 | 48.9 | 42.9 | √ | |

| Dislocation 2P 18650 Nickel strip | 0.15*25.5*18.4(8*9.5) | 18.4 | 8*9.5 | 41.1 | 36.1 | √ | ||

| Dislocation 2P 18650 Nickel strip | 0.15*25.5*19.5(8*9.5) | 19.5 | 8*9.5 | 38.6 | 33.8 | √ | ||

| 3P 18650 Nickel strip | 0.15*44.5*18.4(11*12.5) | 18.4 | 44.5 | 11*12.5 | 27.4 | 24 | √ | |

| 0.15*45*19(12*12) | 19 | 45 | 12*12 | 29.1 | 25.5 | √ | ||

| 0.15*47.5*20.15(12.65*12.65) | 20.15 | 47.5 | 12.6.5*12.65 | 27.4 | 24 | √ | ||

| 0.15*47.5*20.25(13.5*13.5) | 20.25 | 13.5*13.5 | 29.4 | 25.7 | √ | |||

| 4P 18650 Nickel strip | 0.15*63*18.5 (11*12.5) | 18.5 | 63 | 11*12.5 | 21.6 | 18.9 | √ | |

| 0.15*64*19(12*12) | 19 | 64 | 12*12 | 21 | 18.4 | √ | ||

| 0.15*67.95*20.15(12.65*12.65) | 20.15 | 67.95 | 12.65*12.65 | 19.6 | 17.2 | √ | ||

| 0.15*67.7*20.25(13.5*13.5) | 20.25 | 67 | 13.5*13.5 | 21.3 | 18.7 | √ | ||

| 5P 18650 Nickel strip | 0.15*83*19(12*12) | 19 | 83 | 12*12 | 16.4 | 14.4 | √ | |

| 0.15*88.1*20.15(12.65*12.65) | 20.15 | 88.1 | 12.65*12.65 | 19.7 | 17.3 | √ | ||

| 0.15*87.9*20.25(13.5*13.5) | 20.25 | 87.9 | 13.5*13.5 | 16.7 | 14.6 | √ | ||

| 6P 18650 Nickel strip | 0.15*102*19(12*12) | 19 | 102 | 12*12 | 13.5 | 11.9 | √ | |

| 0.15*108.25*20.15 | 20.15 | 108.25 | 12.65*12.65 | 12.6 | 11 | √ | ||

| 0.15*108.1*20.25(13.5*13.5) | 20.25 | 108.1 | 13.5*13.5 | 13.7 | 12 | √ | ||

| 7P 18650 Nickel strip | 0.15*121*19(12*12) | 19 | 121 | 12*12 | 11.5 | 10 | √ | |

| 0.15*128.4*20.15(12.65*12.65) | 20.15 | 128.4 | 12.65*12.65 | 10.7 | 9.4 | √ | ||

| 0.15*128.3*20.25(13.5*13.5) | 20.25 | 128.3 | 13.5*13.5 | 11.6 | 10.2 | √ | ||

| 8P 18650 Nickel strip | 0.15*140*19(12*12) | 19 | 140 | 12*12 | 10 | 8.7 | √ | |

For more details, pls directly contact us.

Applications:

Electronic field: Pure nickel strips are often used to manufacture electronic components, such as resistors, batteries, wires and connectors. Its excellent electrical conductivity and corrosion resistance make it an important material in electronic devices.

Aerospace field: Pure nickel strips are widely used in manufacturing high-temperature parts, such as turbine engine blades, combustion chamber parts and heat exchangers. Pure nickel tape has excellent high temperature stability and corrosion resistance, allowing it to maintain stable performance in extreme working environments.

Chemical industry: Due to its excellent corrosion resistance, pure nickel belt can be used to manufacture chemical equipment, petroleum processing equipment and nuclear power plant parts. It can withstand corrosion from a variety of chemical media, ensuring long-term reliable operation of the equipment.

Oil and Gas Industry: Pure nickel ribbon is widely used in the oil and gas industry to manufacture key equipment such as pipes, valves, pumps, etc. Its corrosion resistance and high temperature capabilities allow it to maintain stable performance in harsh oil and gas environments.

Nuclear industry: Pure nickel ribbon is used in nuclear power plants to manufacture key components such as nuclear reactor parts and nuclear fuel elements. Its high temperature stability and corrosion resistance make it suitable for the special requirements of the nuclear energy sector.

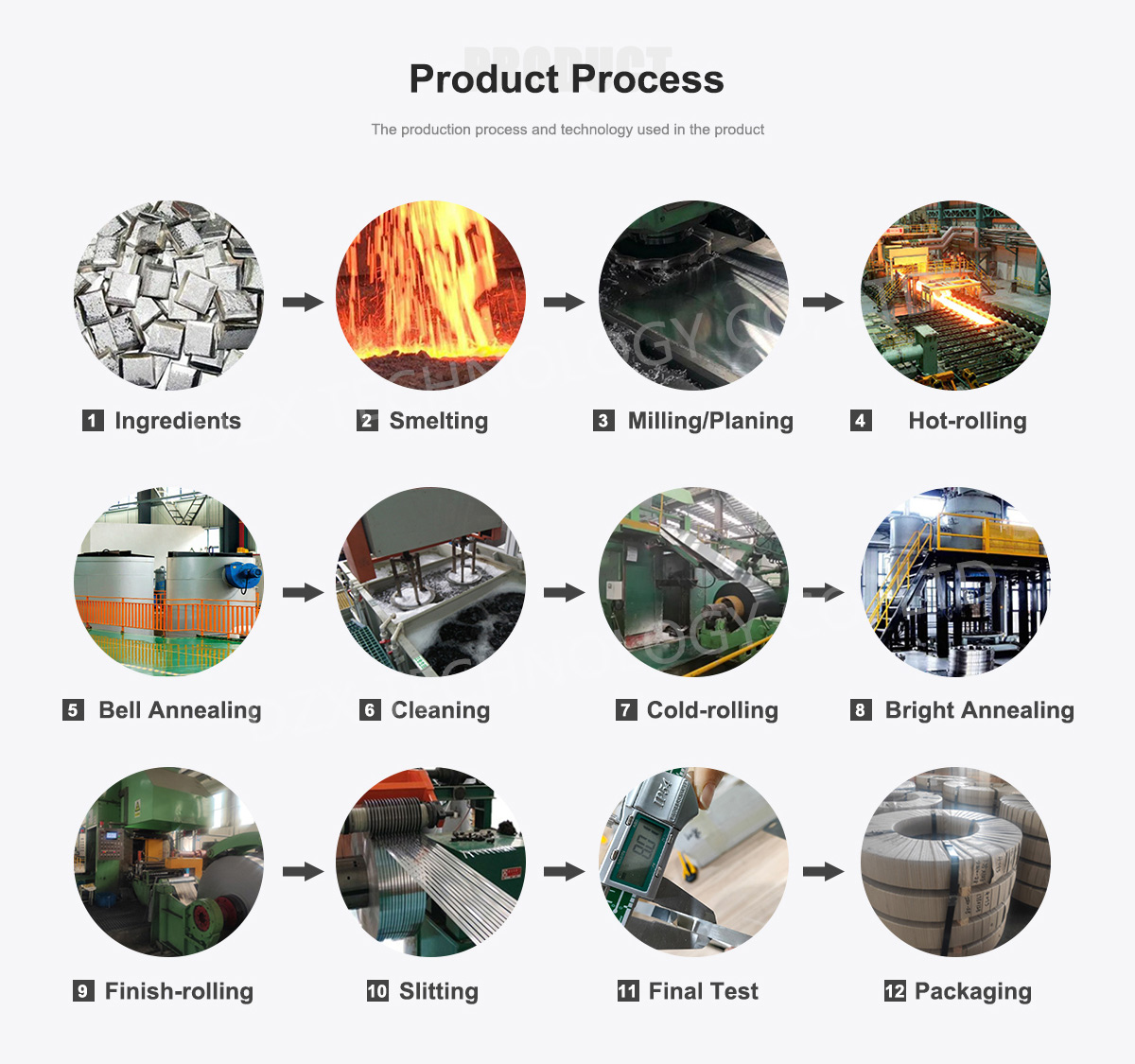

Production Process

Raw material preparation: Select high-purity nickel materials as raw materials to ensure product quality and performance.

Material processing: Pre-process raw nickel materials, including smelting, casting and rolling, to obtain nickel plates or nickel billets that meet the requirements.

Hot rolling: After preheating the nickel plate or billet, it is rolled through a hot rolling mill. During the hot rolling process, the nickel material is gradually rolled into the required strip shape, and the thickness and width of the strip are controlled through multiple rolling and heating passes.

Cold rolling: After hot rolling, the nickel strip needs to be further rolled and processed through the cold rolling process. During the cold rolling process, multiple passes are rolled through the cold rolling mill to make the size of the nickel strip more precise and improve its surface quality and mechanical properties.

Surface treatment: Surface treatment is performed on the cold-rolled pure nickel strip. Common methods include pickling, polishing, plating, etc. to improve the surface finish, corrosion resistance and appearance quality of the nickel strip.

Inspection and quality control: Strict quality inspection is carried out on the pure nickel strips produced, including dimensional measurement, mechanical property testing, chemical composition analysis, etc., to ensure that the product meets the specifications.

Packaging and leaving the factory: The finished pure nickel strips are properly packaged through appropriate packaging methods, marked and recorded, and finally delivered to customers or put into inventory.

Q&A:

What material is pure nickel strip made of?

Pure nickel strip is a metal strip made of high-purity nickel.

What are the applications of pure nickel tape in the electronics industry?

Pure nickel tape is widely used in the electronics industry in resistors, connectors, relays, conductive materials and heat dissipation materials.

What are the main characteristics of pure nickel strip?

The main characteristics of pure nickel strip include excellent electrical conductivity, stable resistivity, good plasticity, weldability and corrosion resistance.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China