0

0

Products Description

Inconel rod is a corrosion-resistant alloy material mainly composed of nickel, chromium and other alloying elements. It has excellent corrosion resistance and can maintain material integrity and stability under various harsh environmental conditions.

Inconel rods are widely used in areas where resistance to corrosive media is required, such as in the chemical, oil and gas industries. It can resist the erosion of acids, alkalis, salts and other corrosive chemicals, including corrosion in strong acids, strong alkali and high temperature and high pressure environments. This makes Inconel rod an ideal material choice for manufacturing critical components such as chemical equipment, oil drilling tools, marine equipment and seawater treatment equipment.

In addition, Inconel rods have excellent antioxidant properties. It can form a strong oxide film in high temperature environments, effectively preventing oxygen and other oxidizing media from corroding materials. This makes it widely used in applications such as high-temperature furnaces, combustion chambers and furnace tubes.

Inconel rods also have good wear and shear resistance and can withstand high stress and mechanical extrusion, making them useful in manufacturing mechanical parts, heat exchangers and valves.

Parameter:

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Production Process:

The production process of Inconel rods generally includes the following steps:

Material preparation: Select high-quality nickel, chromium and other alloying elements as raw materials. These raw materials are usually available in powder or block form.

Material Mixing: Mixing various raw materials together according to a specific recipe. This can be achieved by mechanical stirring, ball milling or other methods. The purpose of mixing is to ensure uniform distribution of various alloying elements.

Melting: The mixed materials are placed in an induction furnace or electric arc furnace and melted. Under high temperature conditions, the raw materials gradually melt and form a liquid alloy.

Casting: Molten alloy is poured into a pre-prepared mold. The casting mold can be in the form of sand, metal or other forms. After the alloy cools and solidifies, a rod-shaped billet is formed.

Heat treatment: Heat treatment is performed on the cast billet to eliminate internal stress and improve the mechanical properties and corrosion resistance of the material. Common heat treatment processes include solution treatment and aging treatment.

Finishing: The heat-treated billet is mechanically processed into the required diameter and length through turning, grinding, forging and other processes. During the finishing process, the rod can also be subjected to surface treatment, such as polishing, pickling, etc.

Testing and Quality Control: The final Inconel bar is subjected to various tests to ensure that it meets specified chemical composition, mechanical properties and dimensional requirements. Common testing methods include chemical analysis, mechanical property testing, dimensional testing, etc.

Packaging and delivery: After quality confirmation, Inconel bars will be packaged according to specifications, length and other requirements, and marked. Finally, the prepared bars can be shipped from the factory and supplied to customers.

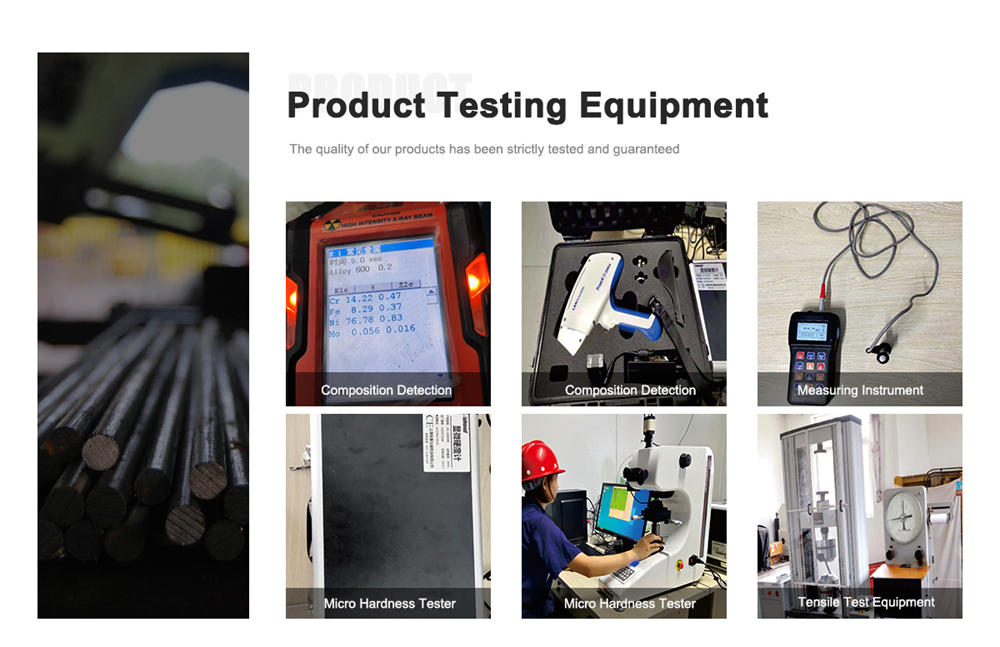

Quality Inspection:

Quality inspection of Inconel rods is an important step in ensuring their performance and quality. The following are some common Inconel rod quality inspection methods:

Chemical composition analysis: Through chemical composition analysis, it can be determined whether the content of each element in Inconel rod meets the specification requirements. Commonly used chemical analysis methods include spectral analysis, atomic absorption spectroscopy and mass spectrometry.

Metallographic microscopic analysis: Metallographic microscopic analysis is to observe and analyze the metallographic structure of Inconel rods to evaluate its grain size, phase composition, grain orientation and other characteristics. This detects the crystal structure and uniformity of the material.

Mechanical Property Testing: Mechanical property testing is used to evaluate the mechanical properties of Inconel rods such as strength, toughness and hardness. Commonly used mechanical property testing methods include tensile testing, impact testing and hardness testing.

Corrosion performance test: The corrosion performance test is used to evaluate the corrosion resistance of Inconel rods in different corrosive media. Commonly used corrosion performance testing methods include salt spray test, corrosion tendency test and electrochemical test.

Dimensional Inspection: Dimensional inspection is used to verify the accuracy of diameter, length and shape of Inconel rods. Commonly used dimensional inspection methods include optical measurement, three-dimensional coordinate measurement, and scanners.

Non-destructive testing: Non-destructive testing methods are used to detect defects and unevenness within Inconel rods without destroying the material itself. Commonly used non-destructive testing methods include ultrasonic testing, eddy current testing and X-ray testing.

Q&A:

What is the manufacturing process of Inconel rods?

The manufacture of Inconel rods usually uses a melting and recrystallization process, including steps such as melting raw materials, forging or rolling forming, heat treatment and finishing.

What are the unique characteristics of Inconel rods compared to other materials?

Compared with other materials, Inconel rods have excellent high-temperature stability, corrosion resistance and oxidation resistance, and can maintain good mechanical properties and dimensional stability in extreme environments.

What are some specific examples of application areas for Inconel rods?

Inconel rods are often used to manufacture turbine engine components, combustion chambers, nozzles, high-temperature furnace tubes, nuclear reactor fuel rods and other key components in high-temperature and corrosive environments.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China