0

0

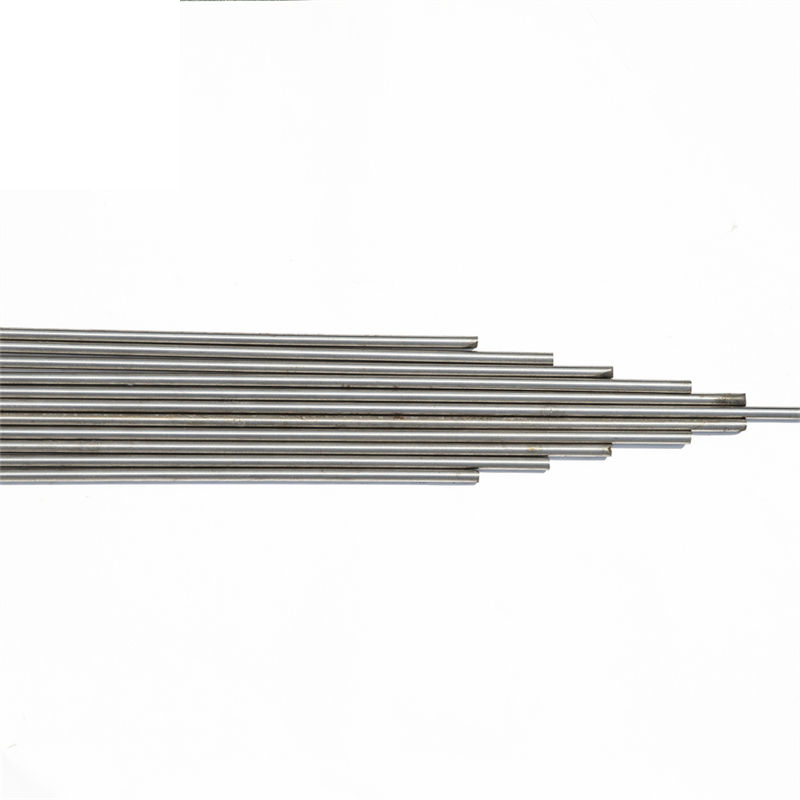

Products Description

Inconel alloy bars play an important role in the automotive industry. This alloy is composed of nickel, chromium and other alloying elements and provides excellent high temperature performance, corrosion resistance and mechanical properties.

The automotive industry has very stringent requirements on materials, as vehicles are exposed to extreme conditions such as high temperatures, corrosion and high stress while driving. Inconel alloy rods can maintain stable performance in high temperature environments and have excellent resistance to oxidation and hot corrosion. This makes it widely used in key components such as automotive engines, turbochargers and exhaust gas treatment systems.

In addition, Inconel alloy rods also have excellent corrosion resistance and can withstand common corrosive media in the automotive industry, such as acid rain, salt water and chemicals. It extends the life of automotive components and improves overall durability.

At the same time, Inconel alloy rods also exhibit excellent mechanical properties and high strength. It can withstand high stress and vibration in the automotive industry and has good resistance to fatigue and deformation. This makes it play an important role in critical components such as braking systems, suspension systems and exhaust systems.

Parameter:

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Characteristic:

High temperature resistance: Inconel alloy rods can maintain good mechanical properties and corrosion resistance in high temperature environments, and are suitable for high temperature components such as automobile engines and exhaust systems.

Corrosion resistance: Inconel alloy rods have excellent resistance to common corrosive media in the automotive industry (such as acidic solutions and salt water, etc.), which can extend the service life of parts.

High strength: Inconel alloy rods have high strength and toughness and can withstand high stress and vibration under automotive working conditions.

Advantage:

Lightweight: Compared with traditional steel, Inconel alloy rods have higher strength and hardness, which can reduce the weight of parts while maintaining structural strength, which is helpful for lightweight design of automobiles.

High-temperature performance: Inconel alloy rods can maintain stable performance in high-temperature environments and can withstand high-temperature corrosion and thermal stress in automobile engines and exhaust systems, improving engine efficiency and reliability.

Fatigue resistance: Inconel alloy rods have excellent fatigue resistance and can maintain stable performance under long-term high stress and vibration environments, extending the service life of parts.

Specific applications:

Specific applications of Inconel alloy rods in the automotive industry include:

Engine parts: Inconel alloy bars are often used to manufacture key parts of automobile engines, such as turbine blades, exhaust valves and cylinder heads. They are able to withstand high temperature and high pressure operating conditions, improving engine performance and reliability.

Exhaust system: Inconel alloy rods are widely used in automobile exhaust systems, such as exhaust pipes and exhaust throats. They resist high-temperature corrosion and thermal stress, extending the life of your exhaust system.

Braking system: Inconel alloy rods can also be used to manufacture components of high-performance braking systems, such as brake discs and brake calipers. They provide stable braking performance under high temperature and high stress conditions, improving the effectiveness and durability of the braking system.

Q&A:

Q: How does Inconel alloy rod compare with aluminum alloy in automotive applications?

Answer: Compared with aluminum alloy, Inconel alloy rods have higher high temperature resistance and corrosion resistance. Therefore, Inconel alloy rods are more suitable for use in automotive parts that need to withstand high temperatures and corrosive environments, such as engines and exhaust systems.

Q: What is the cost of Inconel alloy rods in the automotive industry?

Answer: Inconel alloy rods have a higher cost than traditional steel and aluminum alloys. This is mainly due to the complexity of its alloy composition and manufacturing process. Therefore, when selecting materials, cost and performance requirements need to be considered comprehensively, and the selection should be based on specific application requirements.

Q: Are Inconel alloy rods weldable?

Answer: Yes, Inconel alloy rods are weldable. However, due to its alloy composition and special properties, welding Inconel alloy rods requires specialized welding processes and materials to ensure the quality and performance of the welded joints. When welding Inconel alloy rods, it is recommended to seek professional guidance and support.

Q: What other specific applications do Inconel alloy bars have in the automotive industry?

A: In addition to applications such as engine parts, exhaust systems, and brake systems, Inconel alloy rods can also be used to manufacture other automotive parts, such as turbochargers, fuel nozzles, and sensors. These applications are designed to meet the special requirements of high temperature, high pressure and corrosion resistance in the automotive working environment.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China