0

0

Products Description

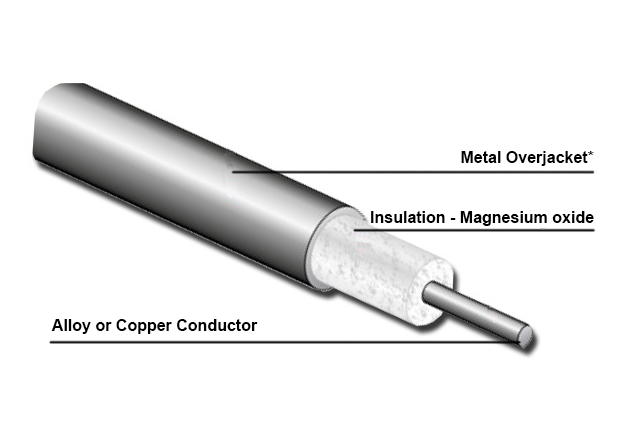

Mineral insulated cables play a crucial role in the oil and gas industry. They use seamless metal sheaths and magnesium oxide insulation materials, providing a cable solution that is resistant to high temperatures, fire and explosion, and corrosion. This type of cable can work stably under extreme industrial temperature and pressure conditions, suitable for temperature monitoring and power transmission of key facilities such as offshore platforms, drilling equipment, and transportation pipelines, ensuring the safety and efficiency of oil and gas extraction, processing, and transportation processes.

Specification

Insulator: 99.6% high purity MgO

Core number: 2, 4, 6

Sheath material: SS321(SS304), SS316, SS310, INCL600, Nicrobell

Dia (mm): from 0.25mm to 12.7mm

Application: connecting with thermocouple and instrument machine

Place of Origin: Jiangsu, China (Mainland)

MOQ: 100m

Certificate: ISO, CQC

Code | Wire Component of the thermocouple | ||

+Positive leg | - Negative Leg | ||

N | Ni-Cr-Si(NP) | Ni-Si-magnesium (NN) | |

K | Ni-Cr(KP) | Ni-Al(Si) (KN) | |

E | Ni-Cr(EP) | Cu-Ni (EN) | |

J | Iron (JP) | Cu-Ni (JN) | |

T | Copper (TP) | Cu-Ni (TN) | |

B | Platinum Rhodium-30% | Platinum Rhodium -6% | |

R | Platinum Rhodium-13% | Platinum | |

S | Platinum Rhodium -10% | Platinum | |

Material | Type | Grade | Working temperature (deg) | Tolerance | Standard | |

Long Term | Short Term | |||||

NiCr-NiSi | K | 1 | -40~1100 | -40~1300 | ±1.5 deg | GB/T 2614-1998 |

2 | ±2.5 deg | |||||

NiCr-CuNi | E | 1 | -40~800 | -40~900 | ±1.5 deg | GB/T 4993-1998 |

2 | ±2.5 deg | |||||

Fe-Constantan | J | 1 | -40~600 | -40~800 | ±1.5 deg | GB/T 4994-1998 |

2 | ±2.5 deg | |||||

Cu-CuNi | T | 1 | -200~300 | -200~400 | ±0.5 deg | GB/T 2903-1998 |

For more details, pls directly contact us.

Core features

Extreme environmental tolerance: MIC cables are designed to operate stably under extreme temperatures and pressures, without fear of harsh conditions in the oil and gas industry.

Excellent fire and explosion prevention characteristics: seamless metal sheathing and inorganic insulation materials ensure safety in fire or explosive environments.

Long term stability and durability: The use of inorganic materials ensures the stability of cables during long-term operation, reducing the need for maintenance and replacement.

High current carrying capacity and low resistance: MIC cables have high current carrying capacity and low resistance characteristics, making them suitable for long-distance power transmission.

Corrosion resistance: effectively resist corrosive substances in oil and natural gas, and extend the service life of cables.

application area

Offshore platforms and drilling equipment: used to monitor and control the temperature of critical equipment on the platform, ensuring operational safety.

Temperature monitoring of transportation pipelines: Real time monitoring of the temperature of the fluid inside the pipeline to prevent overheating or freezing.

Emergency power supply and lighting system: In emergency situations, ensure the power supply of lighting and critical systems.

Signal transmission of control systems: providing stable signal transmission for automation control systems in the oil and gas industry.

User benefits

Improving job safety: The fire and explosion prevention features reduce job risks and ensure the safety of personnel and equipment.

Enhanced system stability: Long term stability and durability reduce system failures and improve operational efficiency.

Reduce maintenance costs: Durability and stability reduce maintenance and replacement costs.

Improving environmental adaptability: Corrosion resistance makes cables suitable for various oil and gas extraction environments.

epilogue

Mineral insulated cables are ideal safety partners in the oil and gas industry, and their high temperature resistance, fire and explosion resistance, and corrosion resistance provide a solid guarantee for the industry. Choose MIC cables to provide a safe, reliable, and efficient power and temperature management solution for your oil and gas operations.

Related Q&A

Q: What are the main advantages of mineral insulated cables in the oil and gas industry?

Answer: The main advantages of MIC cables include their high temperature resistance, fire and explosion resistance, corrosion resistance, and long-term stability, which make them very suitable for harsh environments in the oil and gas industry.

Q: How can mineral insulated cables improve the safety of oil and gas operations?

Answer: MIC cables maintain the integrity of circuits in fire or potentially explosive environments through their fire and explosion prevention characteristics, thereby improving the safety of operations.

Q: What is the maintenance cost of mineral insulated cables in the oil and gas industry?

Answer: Due to the durability and stability of MIC cables, their maintenance costs are relatively low, reducing the costs incurred due to frequent cable replacement.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China