0

0

Products Description

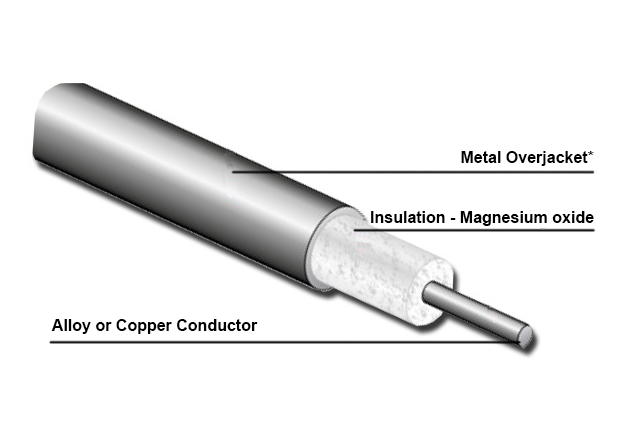

Mineral insulated cables play a crucial role in the chemical industry. It is widely used in temperature monitoring and control of high-temperature reaction vessels, pipeline systems, and chemical equipment. This type of cable can withstand extreme working conditions, including high temperature, high pressure, and corrosive media, ensuring the safety and stability of the production process. By real-time monitoring of temperature changes in reaction containers and pipelines, engineers can adjust production parameters in a timely manner, optimize reaction conditions, and ensure efficient operation of the production process. Due to its reliability and durability, mineral insulated cables are considered one of the indispensable temperature measurement solutions in the chemical industry, providing important support for the normal operation of factories and the guarantee of product quality.

Specification

Insulator: 99.6% high purity MgO

Core number: 2, 4, 6

Sheath material: SS321(SS304), SS316, SS310, INCL600, Nicrobell

Dia (mm): from 0.25mm to 12.7mm

Application: connecting with thermocouple and instrument machine

Place of Origin: Jiangsu, China (Mainland)

MOQ: 100m

Certificate: ISO, CQC

Code | Wire Component of the thermocouple | ||

+Positive leg | - Negative Leg | ||

N | Ni-Cr-Si(NP) | Ni-Si-magnesium (NN) | |

K | Ni-Cr(KP) | Ni-Al(Si) (KN) | |

E | Ni-Cr(EP) | Cu-Ni (EN) | |

J | Iron (JP) | Cu-Ni (JN) | |

T | Copper (TP) | Cu-Ni (TN) | |

B | Platinum Rhodium-30% | Platinum Rhodium -6% | |

R | Platinum Rhodium-13% | Platinum | |

S | Platinum Rhodium -10% | Platinum | |

Material | Type | Grade | Working temperature (deg) | Tolerance | Standard | |

Long Term | Short Term | |||||

NiCr-NiSi | K | 1 | -40~1100 | -40~1300 | ±1.5 deg | GB/T 2614-1998 |

2 | ±2.5 deg | |||||

NiCr-CuNi | E | 1 | -40~800 | -40~900 | ±1.5 deg | GB/T 4993-1998 |

2 | ±2.5 deg | |||||

Fe-Constantan | J | 1 | -40~600 | -40~800 | ±1.5 deg | GB/T 4994-1998 |

2 | ±2.5 deg | |||||

Cu-CuNi | T | 1 | -200~300 | -200~400 | ±0.5 deg | GB/T 2903-1998 |

For more details, pls directly contact us.

In the chemical industry, precise temperature control is the key to ensuring production efficiency and safety. Mineral insulated cables have become an ideal choice for temperature monitoring and control systems in the chemical industry due to their excellent high-temperature resistance, long-term stability, and resistance to chemical corrosion. The MIC cable adopts seamless metal sheath and magnesium oxide insulation material, ensuring reliability and durability in extreme temperature and corrosive environments.

Core features

High temperature resistance: suitable for working environments up to 1000 ° C, meeting the high temperature requirements in chemical processes.

Fire resistance performance: Maintain circuit integrity in the event of a fire, ensuring safe power supply.

Chemical corrosion resistance: Resistance to the erosion of common acids, alkalis, and other chemical substances in the chemical industry.

Long term stability: Inorganic materials ensure stability and durability during long-term operation, reducing maintenance costs.

High current carrying capacity: Compared to other cables of the same cross-section, MIC cables have a higher current carrying capacity.

Non toxic: It does not produce harmful gases at high temperatures, ensuring the safety of the environment and personnel.

application area

Reactor temperature control: Ensure that chemical reactions are carried out at the optimal temperature.

Tank and pipeline monitoring: Monitor and control the temperature of materials inside the tank and pipeline to prevent overheating or freezing.

Heating and cooling system: used for heating or cooling key equipment in chemical production processes.

Environmental monitoring: Monitor the temperature of the surrounding environment of chemical factories to ensure compliance with safety standards.

User benefits

Improve production efficiency: Precise temperature control optimizes the production process, improves yield and quality.

Enhanced safety: fire resistance and chemical corrosion resistance, reducing safety risks.

Reduce maintenance costs: Long term stability reduces the frequency of maintenance and replacement.

Environmentally friendly: halogen-free and non-toxic materials that meet environmental requirements.

epilogue

Mineral insulated cables are an indispensable partner in the chemical industry, providing strong support for chemical production due to their high temperature resistance, stability, and safety. Choose MIC cables to provide a reliable, safe, and efficient warm protection for your chemical enterprise.

Related Q&A

Q: What are the main advantages of mineral insulated cables in the chemical industry?

Answer: The main advantages of mineral insulated cables include high temperature resistance, fire resistance, chemical corrosion resistance, long-term stability, and high current carrying capacity, which make them very suitable for the harsh environment of the chemical industry.

Q: How to ensure the long-term stability of mineral insulated cables in chemical environments?

Answer: By using high-quality seamless metal sheaths and magnesium oxide insulation materials, mineral insulated cables can maintain long-term stability in the chemical industry while reducing the need for maintenance and replacement.

Q: Are mineral insulated cables suitable for all types of chemical environments?

Answer: Yes, mineral insulated cables are suitable for various chemical environments, including corrosive gases, high temperatures, and special chemical reactions, due to their high temperature resistance, chemical corrosion resistance, and halogen-free and non-toxic properties.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China