0

0

Products Description

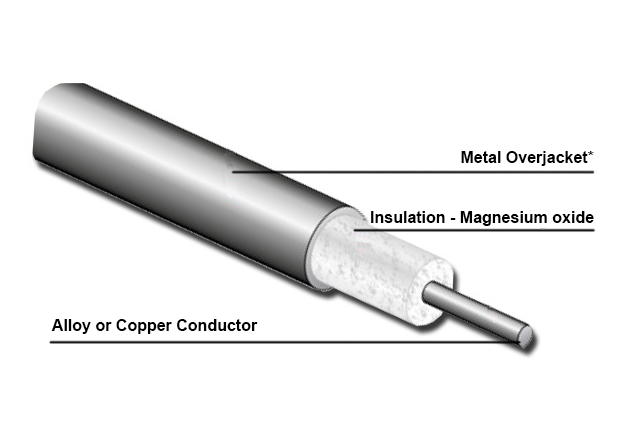

In the high-temperature and ever-changing environment of the metallurgical industry, mineral insulated cables have become indispensable components in monitoring and control systems due to their excellent temperature resistance, stability, and durability. MIC cables adopt advanced mineral insulation technology, both inside and outside are made of metal materials, allowing them to maintain performance unaffected even at extreme industrial temperatures, providing precise solutions for temperature control in metallurgical processes.

In the metallurgical industry, mineral insulated cables are a crucial equipment widely used for temperature monitoring and control in high-temperature smelting furnaces, steelmaking furnaces, and other smelting equipment. This type of cable, due to its high temperature resistance and corrosion resistance, can maintain stability and reliability in extreme working environments, ensuring the safety and efficiency of metallurgical production processes. By monitoring the temperature changes of the smelting equipment, engineers can adjust the smelting process parameters in a timely manner, optimize the temperature distribution inside the furnace, and improve production efficiency and product quality. Therefore, mineral insulated cables are regarded as an indispensable temperature measurement solution in the metallurgical industry, providing important support for the development and production of metallurgical enterprises.

Specification

Insulator: 99.6% high purity MgO

Core number: 2, 4, 6

Sheath material: SS321(SS304), SS316, SS310, INCL600, Nicrobell

Dia (mm): from 0.25mm to 12.7mm

Application: connecting with thermocouple and instrument machine

Place of Origin: Jiangsu, China (Mainland)

MOQ: 100m

Certificate: ISO, CQC

Code | Wire Component of the thermocouple | ||

+Positive leg | - Negative Leg | ||

N | Ni-Cr-Si(NP) | Ni-Si-magnesium (NN) | |

K | Ni-Cr(KP) | Ni-Al(Si) (KN) | |

E | Ni-Cr(EP) | Cu-Ni (EN) | |

J | Iron (JP) | Cu-Ni (JN) | |

T | Copper (TP) | Cu-Ni (TN) | |

B | Platinum Rhodium-30% | Platinum Rhodium -6% | |

R | Platinum Rhodium-13% | Platinum | |

S | Platinum Rhodium -10% | Platinum | |

Material | Type | Grade | Working temperature (deg) | Tolerance | Standard | |

Long Term | Short Term | |||||

NiCr-NiSi | K | 1 | -40~1100 | -40~1300 | ±1.5 deg | GB/T 2614-1998 |

2 | ±2.5 deg | |||||

NiCr-CuNi | E | 1 | -40~800 | -40~900 | ±1.5 deg | GB/T 4993-1998 |

2 | ±2.5 deg | |||||

Fe-Constantan | J | 1 | -40~600 | -40~800 | ±1.5 deg | GB/T 4994-1998 |

2 | ±2.5 deg | |||||

Cu-CuNi | T | 1 | -200~300 | -200~400 | ±0.5 deg | GB/T 2903-1998 |

For more details, pls directly contact us.

Core features

Extreme temperature adaptability: Designed specifically for metallurgical environments up to 1200 ° C, ensuring temperature monitoring in furnaces and steelmaking processes.

Excellent chemical resistance: effectively resist corrosive gases and liquids in metallurgical processes, extending service life.

Sturdy structure: The metal sheath provides additional mechanical protection, resisting impact and pressure, and is suitable for harsh industrial environments.

Thermal stability: Magnesium oxide insulation material ensures that its performance does not decrease under continuous high temperatures.

Easy installation: Simplified installation design makes it easy to quickly deploy in metallurgical equipment.

application area

Furnace temperature control: Real time monitoring of the temperature of the metallurgical furnace to ensure precise control of the smelting process.

Heat treatment equipment: Monitor temperature in the heat treatment furnace to ensure the quality of metal heat treatment.

Continuous casting machine: monitors the temperature during the continuous casting process to ensure casting quality.

Environmental monitoring: Monitor the temperature of the surrounding environment of the metallurgical industry to ensure work safety.

User benefits

Improve production efficiency: Optimize metallurgical production processes through precise temperature control.

Enhance equipment safety: fire resistance and chemical corrosion resistance, reducing the risk of equipment damage.

Reduce long-term operating costs: Durability and stability reduce the need for frequent replacements.

Improving work environment safety: The structure is sturdy, ensuring safe use in high-temperature operations.

epilogue

Mineral insulated cables are ideal temperature monitoring partners in the metallurgical industry, and their high temperature resistance, stability, and durability provide a solid guarantee for high-temperature operations. Choose MIC cables to bring efficient and safe temperature monitoring and management to your metallurgical industry.

Related Q&A

Q: How can mineral insulated cables improve production efficiency in the metallurgical industry?

Answer: Mineral insulated cables help metallurgical enterprises optimize furnace temperature control and heat treatment processes by providing accurate temperature monitoring, thereby improving production efficiency and product quality.

Q: What is the significance of the fire resistance performance of mineral insulated cables for the metallurgical industry?

Answer: The fire resistance performance of mineral insulated cables ensures continuous operation in fire or high-temperature environments, ensuring the safety of critical equipment and smelting processes, and reducing the risk of unexpected shutdowns.

Q: How is the durability of mineral insulated cables reflected in the metallurgical industry?

Answer: The durability of mineral insulated cables is reflected in their metal sheaths and magnesium oxide insulation materials, which can resist high temperatures, impacts, and chemical corrosion in the metallurgical industry, ensuring the long-term stable operation of the cables.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China