0

0

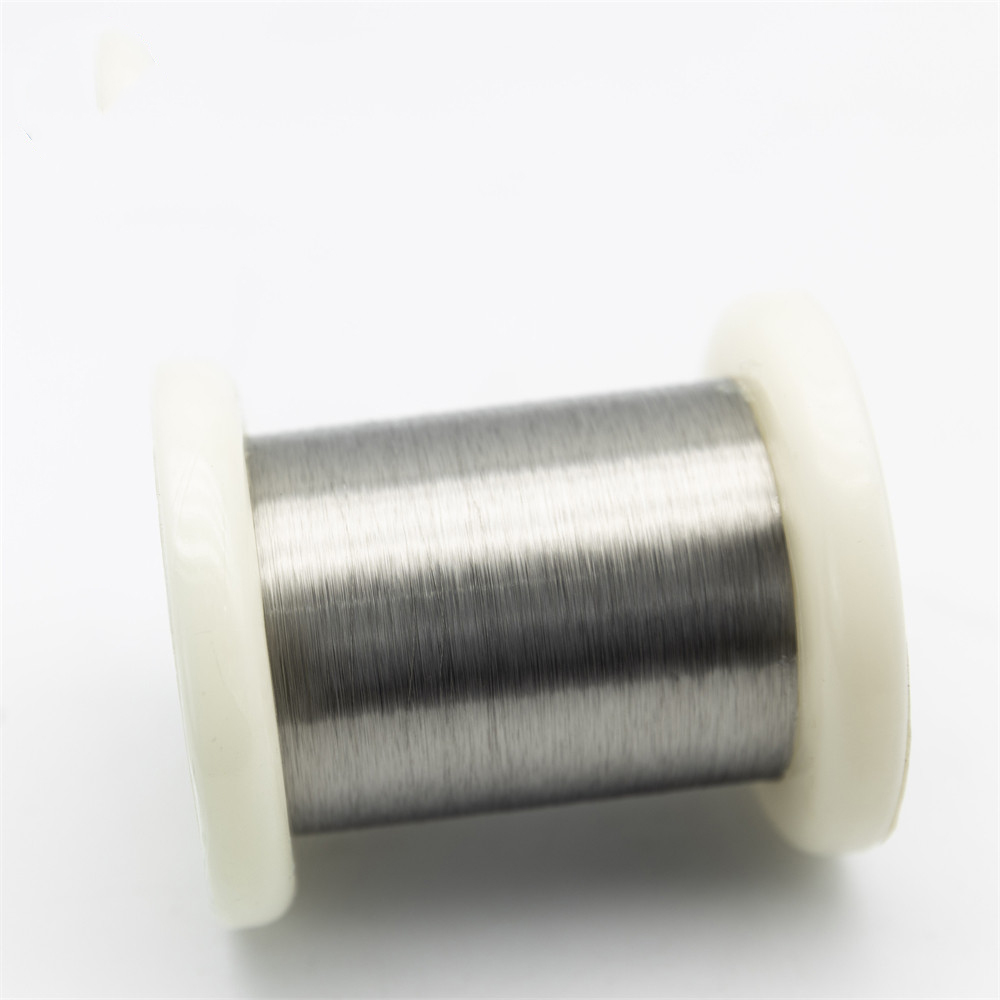

Products Description

Incoloy wire is an advanced alloy wire material that is widely recognized as the golden choice in the industry. It is carefully composed of nickel, iron, chromium and other alloy elements, and has excellent performance and many advantages.

First, Incoloy wire performs well in high temperature environments. It maintains strength and structural integrity stably and is not easily deformed or loosened. This makes it an ideal material for heat treatment equipment such as high-temperature heating equipment, stoves and burners. Incoloy wire still maintains excellent performance under extreme temperature conditions, ensuring reliable operation of equipment.

Secondly, Incoloy wire has excellent corrosion resistance. It can resist the erosion of corrosive media such as acids, alkalis, and salts, making it widely used in fields such as chemical industry, petroleum, and ocean engineering. Whether in corrosive liquids, gas environments or high humidity environments, Incoloy wire can stably maintain its performance and extend the service life of equipment.

In addition, Incoloy wire also exhibits excellent mechanical properties. It can withstand loads in high stress environments and is resistant to stress corrosion cracking. This makes it widely used in various industrial applications where it undertakes important structures and functions.

Overall, Incoloy wire provides a reliable solution for industrial applications with its excellent high temperature performance, corrosion resistance and mechanical properties. Its stability and reliability in the face of extreme working conditions have made it the material of choice across a wide range of industries.

Incoloy series: 800/800H/800HT/825/925

Wire: 0.01-10mm

Strip: 0.05*5.0-5.0*250mm

Bar: φ4-50mm;Length 2000-5000mm

Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm

Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Forms and Standards

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

production process

The production process and production process of Incoloy wire usually include the following steps:

Raw material preparation: Select appropriate Incoloy alloy material as raw material. These raw materials are usually provided in the form of billets or rods, and their chemical composition and physical properties meet specific standard requirements.

Pretreatment: Before starting the production line, the raw materials may need to undergo some pretreatment steps, such as cleaning, pickling, or removing the surface oxide layer, to ensure the purity of the material and surface quality.

Heating and homogenization treatment: Feed the raw materials into the heating furnace and heat them to the appropriate temperature. The heating process helps improve the material's plasticity and deformability, and homogenizes the material's organizational structure.

Thermoforming: At appropriate temperatures, heated and homogenized materials are transformed into the desired wire shape through thermoforming processes such as wire drawing, extrusion, or rolling. These processes process materials into wires of varying diameters, shapes and lengths.

Cold working: The size, shape and surface quality of the wire are further adjusted through cold working processes such as cold drawing or cold rolling. Cold working can increase the strength and hardness of the wire while improving its surface finish.

Cleaning and Surface Preparation: Wire is cleaned and surface treated to remove impurities, grease, or oxides that may be clinging to the surface. This helps improve the surface quality and solderability of the wire.

Inspection and Quality Control: Various inspections and tests are performed on the produced Incoloy wire to ensure that it meets specified chemical composition, physical properties and dimensional requirements. These inspections can include chemical analysis, tensile testing, hardness testing, visual inspection, etc.

Packaging and leaving the factory: Qualified Incoloy wire is properly packaged and labeled to ensure safety and traceability during transportation and storage. The wire is then shipped out of the factory, ready to be supplied to customers.

Most important steps

In the Incoloy wire production process, each step has a certain impact on the quality of the wire, but one of the steps that may have the greatest impact on the quality of the wire is the hot forming step.

Thermoforming is a process in which heated and homogenized materials are transformed into the desired wire shape through thermoforming processes such as wire drawing, extrusion or rolling. In this step, the material undergoes important plastic deformation, and the formation of shape and size mainly depends on the control of thermoforming process parameters.

Factors such as temperature, deformation rate, strain, and design of molds and equipment during the thermoforming process will have an important impact on the quality of the wire. The following are the effects of thermoforming on wire quality:

Crystal structure and grain size: The temperature and deformation conditions during the thermoforming process will affect the grain structure and grain size of Incoloy wire. Larger grain sizes can lead to a decrease in the material's mechanical properties, while fine grain sizes are generally associated with better strength and toughness.

Intrinsic defects: The deformation and stress during the thermoforming process may cause intrinsic defects in the material, such as grain boundary slip, holes, inclusions, etc. These defects may reduce the strength and reliability of the wire.

Dimensional accuracy and shape control: Mold and equipment design and control of operating parameters during the thermoforming process are crucial to the dimensional accuracy and shape control of the wire. Poor mold design or improper operating conditions can lead to dimensional deviations, uneven shapes, or surface defects in the wire.

Other production process steps (such as cold working, cleaning and surface treatment, etc.) also have an important impact on wire quality, but the thermoforming step usually involves the plastic deformation and shape formation of the material, so the impact on wire quality is more significant. However, each step of the entire production process needs to follow strict process control and quality monitoring to ensure that the quality and performance of the final product meet the requirements.

Common problem

During the production process of Incoloy wire, you may encounter some common problems. Here are some common problems and possible solutions:

Surface defects: Defects may appear on the surface of the wire, such as oxide layers, cracks, dents, etc. This may be caused by contamination on the raw material surface, poor production processes or equipment problems. Solutions include using detergents to clean raw materials, optimizing heat treatment parameters, and repairing or replacing equipment.

Dimensional deviation: The dimensions of the wire may deviate from the specified requirements. This may be due to inaccuracies in production equipment, improper operation, or process parameter control issues. Solutions include calibrating and maintaining equipment, optimizing operating parameters, and enhancing dimensional inspection and adjustment.

Grain coarsening: The grain size of the wire may be too large, which may affect the material's mechanical properties and corrosion resistance. This may be caused by the heat treatment temperature being too high or the time being too long. Solutions include optimizing heat treatment parameters and controlling heating and cooling rates to obtain appropriate grain size.

Intrinsic defects: Intrinsic defects such as inclusions, holes, or cracks may exist within the wire, which may reduce the strength and reliability of the wire. Solutions include optimizing the selection of raw materials, strengthening quality inspection control, and optimizing heat treatment parameters to reduce the formation of inherent defects.

Uneven Hardness: The hardness distribution of the wire may be uneven, which may cause processing difficulties or problems in application. Solutions include optimizing heat treatment parameters, cold working processes and annealing treatments to obtain a more uniform hardness distribution.

Poor processability: The processability of Incoloy wire may be affected, such as easy breakage and difficulty in forming complex shapes. Solutions include optimizing heat treatment parameters, cold working processes and annealing treatments, and rationally adjusting processing parameters to improve the plasticity and processability of the material.

FAQ

Is Incoloy wire suitable for manufacturing high-pressure vessels?

Yes, Incoloy wire is often used to manufacture high-pressure vessels due to its high strength and corrosion resistance.

Is Incoloy wire suitable for manufacturing aircraft engine parts?

Yes, Incoloy wire is often used to manufacture high-temperature resistant parts in aircraft engines, such as turbine blades.

What specifications are available for Incoloy wire?

The specifications of Incoloy wire can be customized according to specific needs. Common specifications include diameter, length and weight.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China