0

0

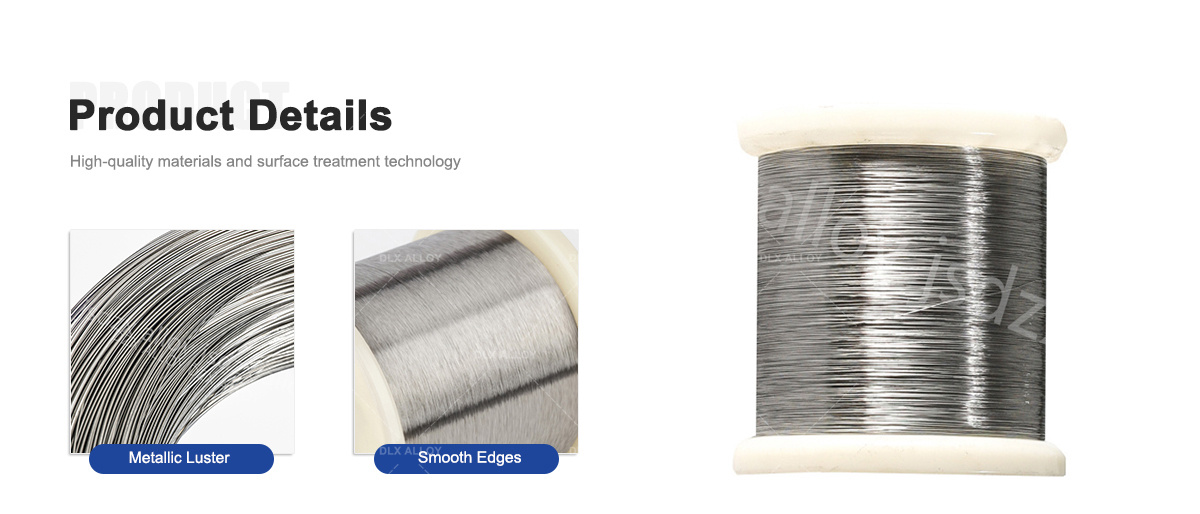

Products Description

Incoloy wire is an advanced alloy wire material mainly composed of elements such as nickel, iron and chromium. It has excellent high temperature resistance and corrosion resistance and is widely used in various harsh industrial environments. Incoloy wire can maintain its strength and stability under high temperature conditions and is not easy to deform or relax, so it is widely used in heat treatment equipment such as high-temperature heaters, stoves and burners. In addition, it also has good corrosion resistance and can resist the erosion of corrosive media such as acids, alkalis, and salts. Therefore, it is widely used in the fields of chemical industry, petroleum, and ocean engineering. Incoloy wire also exhibits excellent mechanical properties, can withstand loads in high stress environments, and is resistant to stress corrosion cracking. In summary, Incoloy wire provides reliable solutions for various industrial applications with its outstanding high temperature performance, corrosion resistance and mechanical properties.

Incoloy series: 800/800H/800HT/825/925

Wire: 0.01-10mm

Strip: 0.05*5.0-5.0*250mm

Bar: φ4-50mm;Length 2000-5000mm

Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm

Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Forms and Standards

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Mechanical behavior:

High strength: Incoloy wire has excellent strength properties and can withstand large forces and loads. It is precision alloyed and heat treated to provide superior mechanical strength. High strength gives Incoloy wire excellent durability and reliability in high stress and load environments.

Good ductility: Incoloy wire has good ductility and plasticity, and can plastically deform under stress without breaking. This makes it easier to bend, coil and weld during forming and processing. At the same time, good ductility also enables Incoloy wire to adapt to various complex shapes and curves.

Excellent toughness: Incoloy wire exhibits good toughness, which means it can maintain stable performance when subjected to impact or vibration loads. This makes it resistant to fracture and fatigue damage in high-stress environments and dynamic loads, ensuring long-term reliable use.

Good thermal creep resistance: Incoloy wire has good thermal creep resistance in high temperature environments. Thermal creep is the continuous deformation of materials due to stress at high temperatures. Incoloy wire can resist creep deformation at high temperatures and maintain the stability of its shape and performance.

Influencing factors:

Alloy composition: The mechanical properties of Incoloy wire are affected by its alloy composition. Different alloying element contents and proportions can adjust the hardness, strength, ductility and other properties of the material. For example, higher nickel and chromium content typically increase a material's strength and corrosion resistance.

Heat treatment: Heat treatment is the process of changing the microstructure and properties of a material by controlling its heating and cooling processes. Proper heat treatment can improve the strength, toughness and heat resistance of Incoloy wire while reducing internal stress and defects.

Cold working: Cold working refers to the process of plastic deformation of metal materials without heating, such as cold drawing, cold rolling, etc. Cold working can increase the strength and hardness of Incoloy wire while improving its surface quality and dimensional accuracy.

Environmental conditions: The use environment also affects the mechanical properties of Incoloy wire. For example, in high-temperature environments, the strength and toughness of materials may change, while in corrosive environments, the corrosion resistance of materials may be affected.

Processing technology: Different processing technologies, such as drawing, welding, annealing, etc., also have an impact on the mechanical properties of Incoloy wire. Reasonable selection and control of processing technology can ensure that the performance of the material meets the requirements.

Material status: Incoloy wire can have different material status, such as cold drawing, heat treatment, annealing, etc. Different material states affect properties such as crystal structure, hardness, strength and toughness.

To sum up, the mechanical properties of Incoloy wire are affected by many factors, including alloy composition, heat treatment, cold working, environmental conditions, processing technology and material status, etc. By properly designing and controlling these factors, the mechanical properties of Incoloy wire can be tuned and optimized to meet the needs of specific applications.

Other factors

The mechanical properties of Incoloy wire may change over time during use. This change may develop gradually and may be influenced by:

Fatigue: If Incoloy wire is operated under cyclic loading, such as being affected by vibration or cyclic stress, fatigue damage will gradually develop. This can cause the material's strength and toughness to decrease, eventually leading to fracture.

Creep: In high temperature environments, Incoloy wire may be affected by creep. Creep is the continued deformation of materials under the action of high temperatures and stress. Over time, creep can cause shape changes, dimensional changes and a reduction in mechanical properties of the material.

Corrosion: If Incoloy wire is exposed to corrosive media, such as acidic or alkaline environments, corrosion will gradually erode the material surface and change its properties. Corrosion can lead to reduced material strength, stress corrosion cracking and other problems.

Oxidation: Incoloy wire may undergo oxidation reactions at high temperatures or in oxidizing environments. Oxidation forms an oxide layer and may have an impact on the material's mechanical properties. For example, a thickening of the oxide layer may lead to an increase in material hardness.

Material aging: Over time, the material structure of Incoloy wire may change, such as grain size growth, phase changes, etc. These changes may have an impact on the mechanical properties of the material.

FAQ

In what equipment and components is Incoloy wire commonly used?

Incoloy wire is often used to manufacture high-temperature equipment and corrosion-resistant components, such as furnace tubes, heat exchangers, storage tanks, etc.

In what environment can Incoloy wire maintain good performance?

Incoloy wire maintains excellent performance in high temperatures, pressures and corrosive environments.

What are the corrosion resistance properties of Incoloy wire?

Incoloy wire has corrosion resistance properties such as acid resistance, alkali resistance, oxidation resistance, and corrosion resistance.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China