0

0

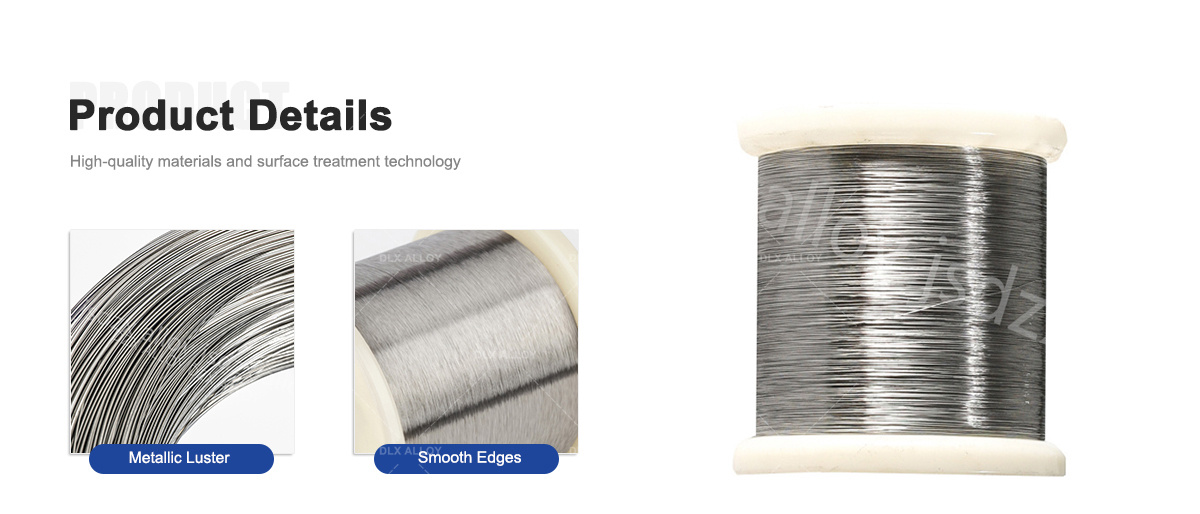

Products Description

Incoloy is a high-temperature alloy composed of elements such as nickel, iron and chromium. It has excellent heat resistance, corrosion resistance and oxidation resistance, and is widely used in industrial fields under high temperature environments. Incoloy wire is a metal wire material made from Incoloy alloy, which has excellent mechanical properties and high temperature resistance. It is widely used in high-temperature heaters, burners, chemical equipment and nuclear energy industries, and is suitable for applications that require working in extreme environments. Incoloy wire is characterized by corrosion resistance, oxidation resistance, high temperature resistance, stress corrosion cracking resistance and excellent mechanical properties, making it an ideal material choice.

Incoloy series: 800/800H/800HT/825/925

Wire: 0.01-10mm

Strip: 0.05*5.0-5.0*250mm

Bar: φ4-50mm;Length 2000-5000mm

Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm

Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Mechanical Properties of Incoloy 925

Tensile Strength, min. | Yield Strength, min. | Elongation, min. | Hardness, min. | ||

Mpa | ksi | Mpa | ksi | % | HRC |

1210 | 176 | 815 | 118 | 24 | 36.5 |

Physical Properties of Incoloy 925

Density | Melting Range | Specific Heat | Electrical Resistivity | ||

g/cm3 | °F | °C | J/kg.k | Btu/lb. °F | µΩ·m |

8.08 | 2392-2490 | 1311-1366 | 435 | 0.104 | 1166 |

Product Forms and Standards

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Parameters

Product brand: Incoloy wire has multiple brands, the common ones include Incoloy 800, Incoloy 800H Incoloy 825 and Incoloy 925, etc.

Parameters: The parameters of Incoloy wire vary according to the specific grade, including diameter, material, tensile strength, elongation and other indicators. Common diameters range from 0.05mm to 5mm.

Characteristics

High temperature resistance: Able to maintain stable performance in high temperature environments, with good oxidation resistance and hot corrosion resistance.

Corrosion resistance: It has excellent resistance to a variety of corrosive media such as acids, alkalis, and salts, and can be used in corrosive environments for a long time.

Mechanical properties: Has good strength and ductility, can withstand high stress loads and resist stress corrosion cracking.

Processing performance: Easy to process and form, and can be manufactured through cold drawing, cold rolling, heat treatment and other processes.

Advantages

High-temperature performance: Maintains stable performance in high-temperature environments, suitable for applications such as high-temperature heaters, stoves, and burners.

Corrosion resistance: Excellent resistance to a variety of corrosive media, suitable for chemical, petroleum, offshore engineering and other fields.

Mechanical properties: It has good strength and ductility and can withstand loads in high stress environments.

Processing performance: easy to process and shape, can meet the needs of different applications.

Application

Incoloy wire is widely used in the following fields:

Oil and Gas Industry: Used in corrosion-resistant components such as oil well equipment, pipes and valves.

Chemical industry: used in applications in high-temperature, corrosive environments such as chemical equipment, reactors and furnaces.

Energy industry: used in heat treatment equipment such as high-temperature heaters, boilers and burners.

Nuclear energy industry: used in nuclear fuel elements and other nuclear equipment in nuclear reactors.

FAQ

Q1: What high temperature environments is Incoloy wire suitable for?

A1: Incoloy wire is suitable for high-temperature environments such as high-temperature heaters, stoves, and burners.

Q2: What are the main characteristics of Incoloy wire?

A2: The main characteristics of Incoloy wire include high temperature resistance, corrosion resistance, good mechanical properties and processing properties.

Q3: In what fields is Incoloy wire widely used?

A3: Incoloy wire is widely used in petroleum, chemical, energy and nuclear energy industries.

Q4: What are the advantages of Incoloy silk?

A4: The advantages of Incoloy wire include high temperature performance and corrosion resistance. Incoloy wire is a high-temperature alloy wire material composed of elements such as nickel, iron and chromium. It has excellent heat resistance, corrosion resistance and oxidation resistance, and is widely used in industrial fields under high temperature environments.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China