0

0

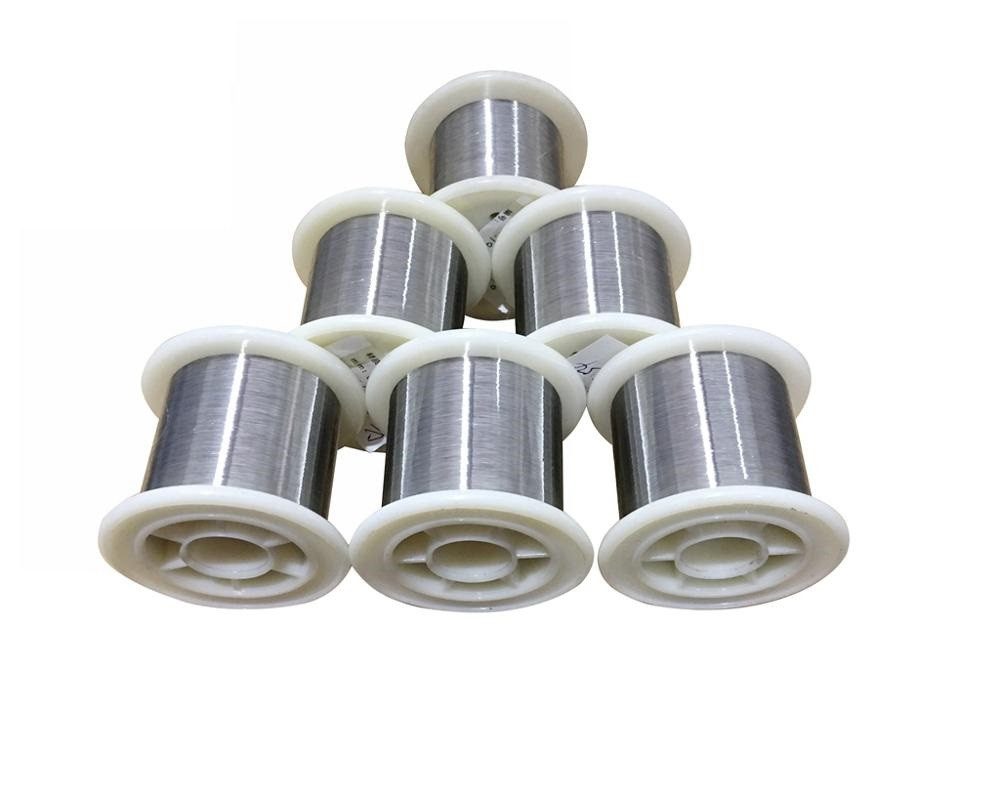

Products Description

Incoloy wire is a high-performance alloy wire material composed of nickel, iron, chromium and other elements. It is widely used in industrial fields under high temperature, corrosive and oxidizing environments. Incoloy wire has ex cellent heat resistance and can maintain stable mechanical properties and structural integrity at extremely high temperatures. In addition, it also exhibits excellent corrosion resistance and has good resistance to corrosive media such as acids, alkalis, and salts. Incoloy wire also has excellent resistance to stress corrosion cracking and can be used for a long time in high stress environments without breaking. This makes it the material of choice for many key applications, including chemicals, petroleum, energy, aerospace and more. In short, Incoloy wire provides reliable solutions to industrial needs under various extreme working conditions with its excellent high temperature performance, corrosion resistance and stress corrosion cracking resistance.

cellent heat resistance and can maintain stable mechanical properties and structural integrity at extremely high temperatures. In addition, it also exhibits excellent corrosion resistance and has good resistance to corrosive media such as acids, alkalis, and salts. Incoloy wire also has excellent resistance to stress corrosion cracking and can be used for a long time in high stress environments without breaking. This makes it the material of choice for many key applications, including chemicals, petroleum, energy, aerospace and more. In short, Incoloy wire provides reliable solutions to industrial needs under various extreme working conditions with its excellent high temperature performance, corrosion resistance and stress corrosion cracking resistance.

Incoloy series: 800/800H/800HT/825/925

Wire: 0.01-10mm

Strip: 0.05*5.0-5.0*250mm

Bar: φ4-50mm;Length 2000-5000mm

Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm

Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Forms and Standards

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Corrosion resistance

Acid resistance: Incoloy wire can show good corrosion resistance in acidic media. Its high content of nickel and chromium elements can interact with acidic substances to form a dense oxide surface layer, which can effectively resist the corrosion of acidic media.

Alkali resistance: Incoloy wire has good corrosion resistance in alkaline environments. Chromium can react with alkaline substances to form a dense oxide layer to prevent erosion by alkaline media.

Oxidation resistance: The alloy composition of Incoloy wire contains a high proportion of elements such as nickel and chromium, which gives it good oxidation resistance. In high-temperature environments, nickel and chromium elements can react with oxygen to form a stable oxide layer to prevent further oxidation reactions, thereby providing good anti-oxidation protection.

Resistant to corrosive media: Incoloy wire can exhibit excellent corrosion resistance in various corrosive media. Whether it is acidic, alkaline, salt solution, seawater and other corrosive media, Incoloy wire can provide reliable corrosion resistance and reduce material corrosion losses.

Influencing factors

Alloy composition: The alloy composition of Incoloy wire is one of the key factors affecting its corrosion resistance. The content and proportion of elements in the alloy can adjust the chemical properties of the alloy, thereby affecting its resistance to different corrosive media. For example, high levels of nickel and chromium can improve acid and alkali resistance.

Oxide layer: The oxide layer formed on the surface of Incoloy wire plays an important role in its corrosion resistance. This oxide layer forms a barrier that prevents corrosive media from directly contacting the alloy surface. A suitable oxide layer can provide additional protection and reduce the occurrence of corrosion.

Temperature and Environment: Temperature and environmental conditions have a significant impact on the corrosion resistance of Incoloy wire. Different corrosive media may produce different corrosion behaviors on alloys at different temperatures. Some environmental conditions, such as acidic, alkaline, salt solutions, etc., may aggravate the degree of corrosion.

Machining and Heat Treatment: The machining and heat treatment of Incoloy wire may also affect its corrosion resistance. Proper processing and heat treatment can improve the stability of grain boundaries and crystal structure, thereby improving the corrosion resistance of the alloy.

Conditions of use: Conditions of use, such as stress, strain, atmosphere, etc., will also affect the corrosion resistance of Incoloy wire. For example, alloys may be more susceptible to corrosion damage under high stress or high strain conditions. In addition, different corrosive substances may exist in different atmospheres, which may affect the corrosion performance of the alloy.

To sum up, the corrosion resistance of Incoloy wire is comprehensively affected by multiple factors such as alloy composition, oxide layer, temperature and environment, processing technology and heat treatment, and usage conditions.

Specific influencing elements

Among the alloy components of Incoloy wire, the contents of nickel (Ni) and chromium (Cr) have the greatest impact on corrosion resistance. The following are their main effects on corrosion resistance:

Nickel (Ni): Nickel is the main alloying element in Incoloy wire and has good corrosion resistance. Nickel can react with oxygen in the corrosive medium to form a dense oxide layer that prevents further oxidation reactions, thus providing anti-oxidation protection. Nickel can also improve the toughness and stress corrosion resistance of the alloy, giving it better corrosion resistance in harsh environments.

Chromium (Cr): Chromium is another key alloying element that also plays an important role in the corrosion resistance of Incoloy wire. Chromium can react with oxygen to form a dense chromium oxide layer. This oxide layer can prevent corrosion media from eroding the alloy. High chromium content can improve the acid and alkali resistance of the alloy, giving it better stability in acidic and alkaline environments.

In addition to nickel and chromium, other alloying elements such as molybdenum (Mo), copper (Cu), titanium (Ti), etc. can also have a certain impact on the corrosion resistance of Incoloy wire. For example, the addition of molybdenum can improve the sulfuric acid corrosion resistance of the alloy, and the addition of copper can improve the acid resistance.

FAQ

Q:What material is Incoloy wire made of?

A:Incoloy wire is composed of nickel, iron, chromium and other elements.

Q:What are the main characteristics of Incoloy wire?

A:Incoloy wire has the main characteristics of good corrosion resistance, excellent high temperature performance, and stable mechanical properties.

Q:What fields are Incoloy wire suitable for?

A:Incoloy wire is widely used in chemical industry, petroleum, energy, aerospace and other fields.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China