0

0

Products Description

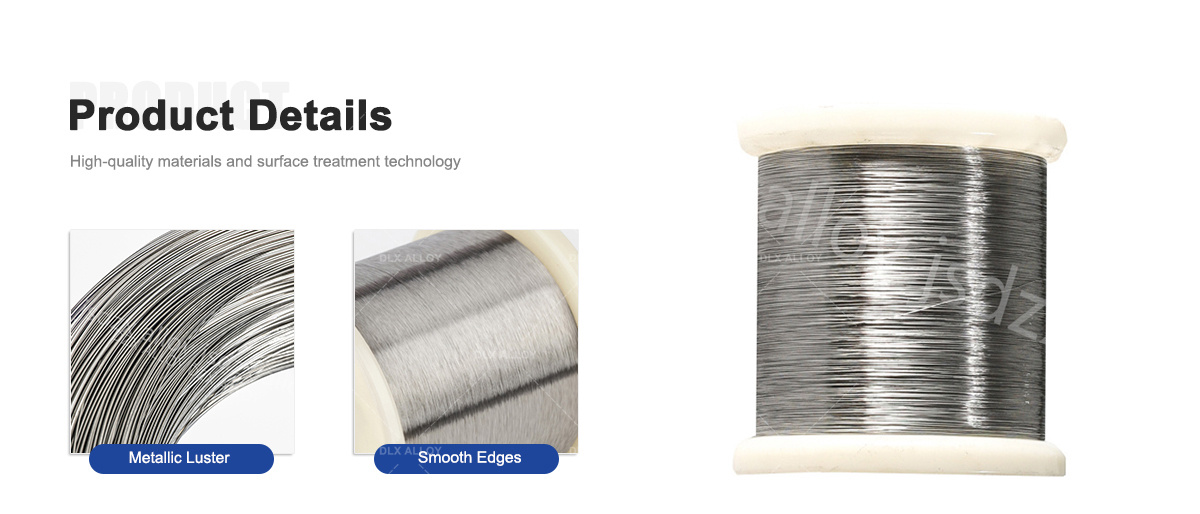

Incoloy wire is a high-temperature alloy wire material mainly composed of elements such as nickel, iron and chromium. It has excellent heat resistance, corrosion resistance and oxidation resistance, and is suitable for industrial applications in various high temperature environments. Incoloy wire is known for its excellent mechanical properties and high temperature resistance and is widely used in high temperature heaters, burners, chemical equipment and nuclear energy industries. This wire is resistant to corrosion, oxidation, high temperatures and stress corrosion cracking, along with excellent mechanical properties, making it an ideal material choice. Whether in extreme environments or where high temperatures and corrosive conditions are required, Incoloy wire provides reliable performance and long-term durability.

Incoloy series: 800/800H/800HT/825/925

Wire: 0.01-10mm

Strip: 0.05*5.0-5.0*250mm

Bar: φ4-50mm;Length 2000-5000mm

Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm

Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Forms and Standards

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

High temperature resistance

High Temperature Stability: Incoloy wire maintains its mechanical properties and chemical stability in high temperature environments. It can withstand prolonged exposure to high temperatures without significant deformation, loosening or damage.

High melting point: The alloy composition of Incoloy wire contains high melting point metal elements, such as nickel and chromium, giving it a higher melting point. This makes Incoloy wire less likely to melt or soften at high temperatures.

Oxidation resistance: Incoloy wire can form a stable oxide surface layer to prevent high-temperature oxidation reactions. This helps protect the wire from oxidation, corrosion and degradation.

Hot corrosion resistance: Incoloy wire has good hot corrosion resistance and can resist the erosion of corrosive media at high temperatures, such as high-temperature acidic and alkaline environments.

High strength maintenance: Incoloy wire maintains high strength at high temperatures and is not prone to plastic deformation or fracture. This makes it a reliable material choice in high temperature stress environments.

Wide Range of High Temperature Applications: Due to its high temperature resistance, Incoloy wire is widely used in many high temperature applications including furnace heating elements, resistive heating wires for high temperature installations, heaters and heat exchangers in the petroleum and chemical industries, etc.

Influencing factors

The high temperature stability of Incoloy wire can be affected by stress conditions. Stress conditions include factors such as mechanical stress, thermal stress, and strain rate.

Mechanical stress: At high temperatures, mechanical stress can lead to plastic deformation and stress relaxation of materials. If Incoloy wire is subjected to excessive mechanical stress at high temperatures, its mechanical properties may be reduced or plastic deformation may occur. This may cause shape distortion, breakage or fatigue damage to the wire.

Thermal Stress: Thermal stress is stress due to temperature gradients. In high temperature environments, Incoloy wire may be affected by thermal expansion and contraction, resulting in internal stresses in different temperature zones. If thermal stress exceeds the material's ability to withstand stress cracking or deformation, it may occur.

Strain rate: At high temperatures, strain rate can also have an impact on the high temperature stability of Incoloy wire. Rapid loading or high strain rates may cause creep, plastic deformation or stress concentration in the material, thereby affecting its high temperature stability and mechanical properties.

Therefore, when designing and using Incoloy wire for high-temperature applications, the impact of stress conditions on its high-temperature stability needs to be comprehensively considered. Reasonable design and application conditions, as well as appropriate stress control and strain rate control, can improve the high temperature stability and service life of Incoloy wire.

Related parameters

High melting point: The alloy composition of Incoloy wire contains high melting point metal elements, such as nickel, chromium and iron. These elements give Incoloy wire a high melting point and can maintain a stable solid state in high temperature environments.

High strength retention: Incoloy wire can maintain high strength at high temperatures. It has good high-temperature tensile strength and ductility, and can withstand high-temperature stress and load without being prone to plastic deformation or fracture.

Thermal expansion coefficient: Incoloy wire has a moderate thermal expansion coefficient, which makes it better matched with the thermal expansion of other materials at high temperatures. This is important for process operations such as joining, welding or assembly in high temperature environments.

Thermal conductivity: Incoloy wire has high thermal conductivity and can conduct heat efficiently. This allows it to evenly distribute and transfer heat in high temperature applications to provide a more stable heating effect.

Thermal cycle performance: Incoloy wire has good thermal cycle performance and can withstand multiple cycles of thermal expansion and contraction in high-temperature changing environments. This makes it suitable for hydronic heating or thermal shock environments in high temperature applications.

High temperature application range: Due to its excellent high temperature resistance, Incoloy wire is widely used in many high temperature applications, such as furnace heating elements, resistance heating wires, heaters and heat exchangers in the petroleum and chemical industries, etc.

FAQ

Q: In what fields is Incoloy wire widely used?

Answer: Incoloy wire is widely used in many fields, including petroleum and chemical industries, energy fields, aerospace, marine engineering, electronic equipment, heat treatment and laboratory equipment, etc. It is often used in the manufacture of heating elements, resistance wires, sensors, anti-corrosion equipment, etc.

Q: What are the main advantages of Incoloy wire?

Answer: Incoloy wire has several major advantages. It has excellent resistance to hot corrosion and remains stable in high temperatures and corrosive environments. In addition, it has good high-temperature strength and ductility and can withstand high-temperature stress and load. Its high melting point and thermal cycling properties are also among its advantages.

Q: What is the maximum usable temperature of Incoloy wire in high temperature environment?

Answer: The maximum usable temperature of Incoloy wire varies depending on the specific alloy type and application conditions. Typically, Incoloy 800 series alloys can be used at temperatures up to 1100°C (2012°F), while Incoloy 825 series alloys can be used at temperatures up to 870°C (1598°F). Specific maximum temperature limits should be referred to the relevant material specifications and technical data provided by the manufacturer.

Q: What is the high temperature processability of Incoloy wire?

Answer: Incoloy wire has good high temperature processing performance. It can be shaped, welded and connected through heat treatment, cold working and hot working. During high-temperature processing, attention needs to be paid to appropriate processing temperature, speed and strain rate to avoid overheating, over-deformation or stress concentration of the material.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China