0

0

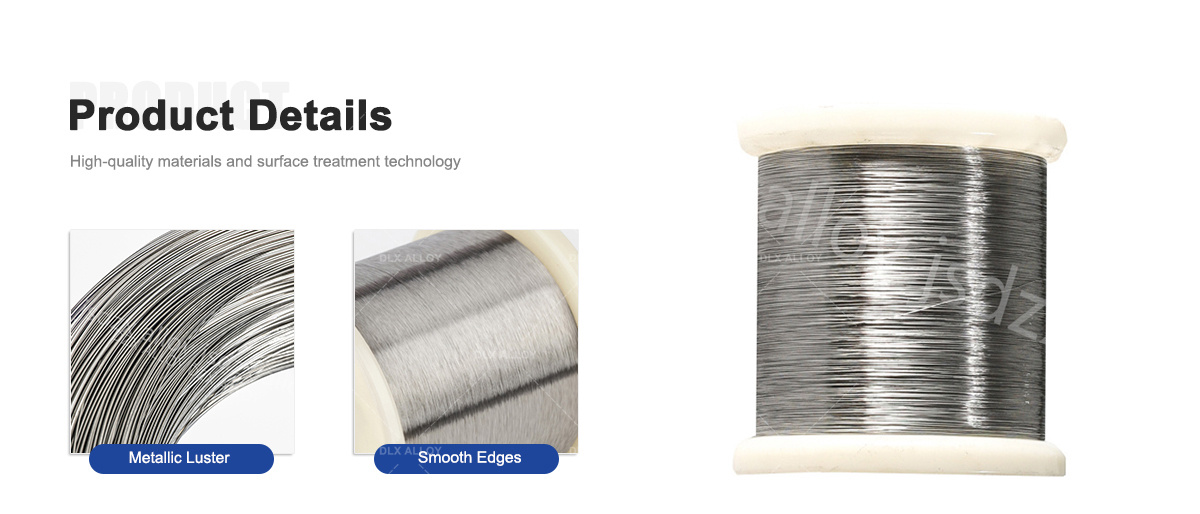

Products Description

Incoloy wire is an advanced alloy wire material that provides the industry with superior performance and reliability. Its main components include alloying elements such as nickel, iron and chromium, which give it unique properties.

First, Incoloy wire exhibits outstanding performance under high temperature conditions. It maintains stable strength and structure and is not susceptible to deformation or relaxation. This makes it the material of choice for thermal processing equipment such as high-temperature heaters, stoves and burners. Incoloy wire maintains its performance in extreme temperature environments, ensuring reliable operation of equipment.

Incoloy series: 800/800H/800HT/825/925

Wire: 0.01-10mm

Strip: 0.05*5.0-5.0*250mm

Bar: φ4-50mm;Length 2000-5000mm

Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm

Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Forms and Standards

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

Ease of processing:

Plasticity: Incoloy wire has high plasticity and can be plastically deformed through hot or cold working. This makes it suitable for various processing techniques, such as drawing, extrusion, rolling, etc.

Weldability: Incoloy wire has good weldability and can be connected through common welding methods, such as arc welding, TIG welding, MIG welding, etc. This makes it easier to process and assemble during manufacturing.

Machinability: Incoloy wire exhibits good machinability in terms of cutting. It can be processed through conventional cutting processes such as turning, drilling, milling, etc. to meet specific shape and size requirements.

Deformation ability: Incoloy wire can be deformed by cold working, such as cold drawing or cold rolling. This deformation ability allows it to create a variety of filaments, wires and complex shapes.

Processability Adjustment: Through appropriate heat treatment and thermal processing operations, the processability properties of Incoloy wire can be further adjusted to meet specific application needs.

It should be noted that due to the high temperature characteristics of Incoloy alloys, appropriate processing measures and process parameters may be required to ensure that the properties and oxidation resistance of the alloy are maintained during processing.

Influencing factors:

Alloy composition: The alloy composition of Incoloy wire plays an important role in its ease of processing. Different alloy compositions will affect the hardness, plasticity and deformation ability of the material. Generally, higher nickel content and the addition of other alloying elements can improve the material's plasticity and ease of processing.

Heat Treatment: The processability of Incoloy wire can be improved through a proper heat treatment process. Heat treatment can change the grain size, structure and hardness of the material, thereby affecting its plasticity and deformation ability. Reasonable heat treatment process can improve the plasticity and processability of the material.

Temperature: Processing temperature has a significant impact on the ease of processing of Incoloy wire. Higher temperatures can reduce the material's hardness and strength and increase its plasticity and deformability, thereby improving processability. However, too high a temperature may cause excessive softening and thermal deformation of the material.

Processing technology and process parameters: Selection of appropriate processing technology and process parameters is very important to achieve ideal processability. Different processing methods, such as drawing, extrusion, rolling, cutting, etc., and corresponding process parameters, such as deformation rate, cooling rate, cutting speed, etc., will affect the processability of the material.

Material condition: The initial condition of Incoloy wire also affects its ease of processing. For example, cold-rolled materials typically have higher strength and hardness, so more processing force and appropriate machining processes may be required to achieve the desired shape and size.

Specific influencing factors of alloy composition

The alloy composition of Incoloy wire has the following specific manifestations of its ease of processing:

Plasticity and deformation ability: Elements such as nickel, chromium and iron in the alloy composition play an important role in improving the plasticity and deformation ability of Incoloy wire. Higher nickel content can increase the plasticity of the material, making it easier to undergo plastic deformation such as drawing, extrusion, and cold rolling. At the same time, the addition of appropriate amounts of chromium and iron elements can improve the strength and hardness of the material and maintain its stable shape and size.

Heat treatment response: The alloy composition also has an important influence on the heat treatment response of Incoloy wire. Different alloy compositions play a key role in controlling phase transformation, precipitation and grain size during heat treatment. Proper heat treatment can improve the material's structure and adjust the balance between hardness and plasticity, thereby improving its processability.

Anti-oxidation performance: The selection of alloy components has an important impact on the anti-oxidation performance of Incoloy wire. The addition of high nickel content and other alloying elements can improve the oxidation resistance of the material and reduce the formation and growth rate of the oxide layer. This is particularly important for Incoloy wire that is processed and used in high-temperature environments, because a lower oxidation rate can reduce oxidation and corrosion on the material surface, maintaining its easy processability and performance stability.

Heat treatment method:

Solution Annealing: Solution Annealing is a common heat treatment method that heats Incoloy wire to a high enough temperature to evenly distribute the alloy elements in its solid solution phase. Subsequently, rapid cooling (such as water quenching or air cooling) is used to fix the uniform distribution of alloying elements. This heat treatment method can eliminate or reduce the inhomogeneity of grains and phases in the material, improving its plasticity and ease of processing.

Cold Working and Annealing: The strength and hardness of Incoloy wire can be increased through cold deformation (such as cold drawing or cold rolling), but its plasticity may be reduced. To improve processability, annealing can be performed. Annealing is to heat the cold deformed material to an appropriate temperature and then cool it appropriately to reduce the impact of cold deformation on the plasticity of the material. This restores the plasticity and deformability of the material and improves processability.

Precipitation Hardening: Precipitation hardening is a method to increase the hardness and strength of materials by controlling the precipitation of alloy phases. For some Incoloy alloys, through appropriate heat treatment, the solute elements in the alloy can be prompted to form fine precipitation phases, thereby improving the strength of the material. However, precipitation hardening treatments may reduce the material's plasticity and ease of processing. Therefore, when performing precipitation hardening treatment, a balance between material hardness and ease of processing needs to be considered based on specific application requirements.

FAQ

What is the difference between Incoloy wire and stainless steel?

Incoloy wire has higher corrosion resistance and high temperature performance than stainless steel, and is suitable for more harsh working environments.

Is Incoloy wire suitable for use in chemical plants?

Yes, Incoloy wire is often used in chemical plants to make corrosion-resistant equipment and pipes.

Is Incoloy wire suitable for use in seawater environments?

Yes, Incoloy wire has good corrosion resistance to seawater and is often used in marine engineering and offshore equipment.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China