0

0

Products Description

Incoloy wire is a high-performance alloy wire composed of nickel, iron, chromium and other elements. It has excellent corrosion resistance and can maintain excellent performance in high temperatures, high pressures and corrosive environments. Incoloy wire is widely used in chemical industry, petroleum, energy, aerospace and other fields to manufacture high-temperature equipment and corrosion-resistant components, such as furnace tubes, heat exchangers, storage tanks, etc. Its material is strong and durable, has good mechanical properties and thermal stability, and can withstand extreme working conditions. Incoloy wire is widely recognized and used in the industrial field, providing reliable material solutions for various projects.

Incoloy series: 800/800H/800HT/825/925

Wire: 0.01-10mm

Strip: 0.05*5.0-5.0*250mm

Bar: φ4-50mm;Length 2000-5000mm

Pipe: φ6-273mm;δ1-30mm;Length 1000-8000mm

Sheet: δ 0.8-36mm;Width 650-2000mm;Length 800-4500mm

Chemical Composition Requirement

Item | 800 | 800H | 800HT | 825 | 925 |

C | ≤0.1 | 0.05-0.1 | 0.06-0.1 | ≤0.05 | ≤0.03 |

Mn | ≤1.5 | ≤1.5 | ≤1.5 | ≤1 | ≤1 |

Fe | rest | rest | rest | rest | rest |

P | -- | -- | -- | ≤0.02 | ≤0.03 |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.03 | ≤0.03 |

Si | ≤1 | ≤1 | ≤1 | ≤0.5 | ≤0.5 |

Cu | ≤0.75 | ≤0.75 | ≤0.75 | 1.5-3 | 1.5-3 |

Ni | 30-35 | 30-35 | 30-35 | 38-46 | 42-46 |

Al | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.2-1 | 0.15-0.5 |

Ti | 0.15-0.6 | 0.15-0.6 | 0.15-0.6 | 0.6-1.2 | 1.9-2.4 |

Cr | 19-23 | 19-23 | 19-23 | 19.5-23.5 | 19.5-23.5 |

Mo | -- | -- | -- | 2.5-3.5 | 2.5-3.5 |

Shape | Size (mm) |

Wire | 0.5-7.5 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Custom made |

Sheet/Plate | Custom made |

Product Forms and Standards

Product Form | Standard |

Rod, bar & Wire | ASTM B805 |

Plate, sheet & strip | ASTM B872 |

Seamless pipe and tube | ASTM B983 |

Forging | ASTM B637 |

For more details, pls directly contact us.

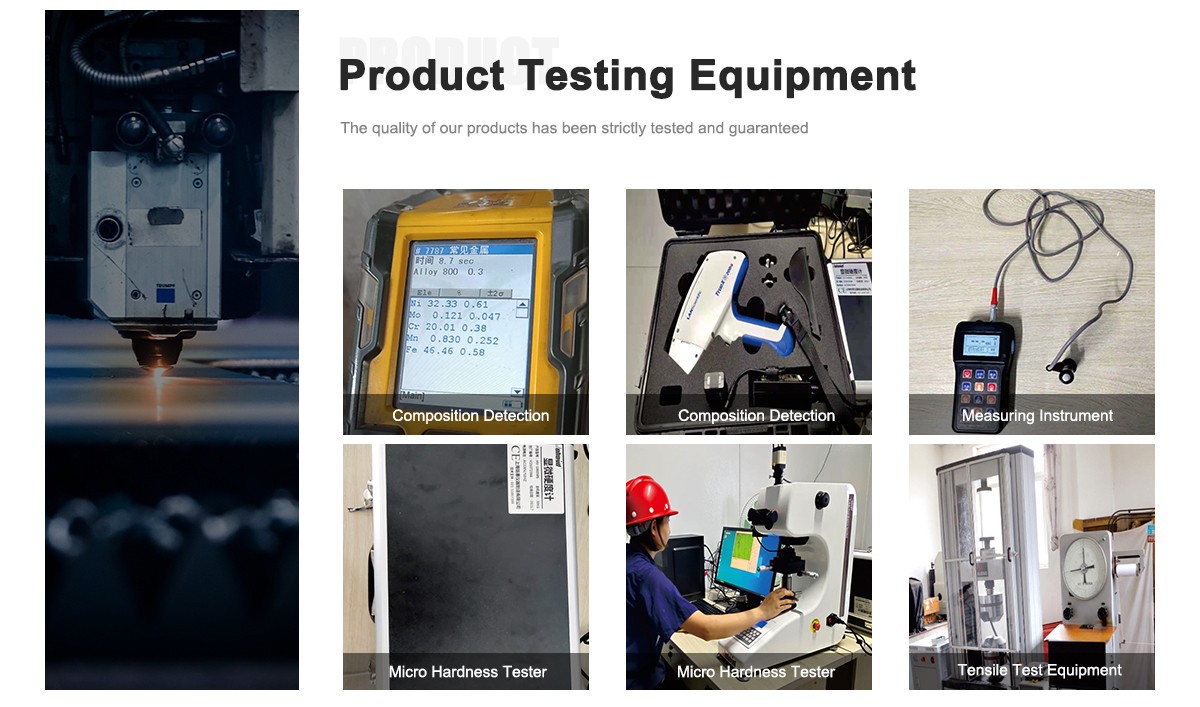

Quality Inspection

Quality testing of Incoloy alloy wire is an important step in ensuring that products meet specified requirements. The following are some common Incoloy alloy wire quality testing methods:

Chemical composition analysis: Chemical composition analysis is a key step in determining the alloy composition of Incoloy alloy wire. Analysis is usually performed using equipment such as spectrometers, mass spectrometers or chemical analyzers. Compare the analysis results with the specified chemical composition requirements to ensure that the composition of the alloy wire meets the requirements.

Mechanical property testing: Mechanical property testing is used to evaluate the mechanical properties of Incoloy alloy wire, such as tensile strength, yield strength, elongation, etc. Commonly used test methods include tensile testing, impact testing and hardness testing. These tests can evaluate the strength, toughness and reliability of the alloy wire by examining the mechanical property parameters of the sample.

Corrosion performance test: The corrosion performance test is used to evaluate the corrosion resistance of Incoloy alloy wire in different corrosive media. Commonly used corrosion performance testing methods include immersion testing, corrosion rate determination and electrochemical testing. These tests determine the corrosion resistance of alloy wires in specific corrosive environments and evaluate their durability in practical applications.

Metallographic analysis: Metallographic analysis is used to evaluate the structure and grain size of Incoloy alloy wire. Commonly used metallographic analysis methods include metallographic microscope observation, microhardness testing and grain size determination. These analyzes can provide information about the grain structure, grain size, and phase content of the alloy wire to evaluate its structural properties and heat treatment effects.

Dimensional inspection: Dimensional inspection is used to ensure that Incoloy alloy wire meets the specified diameter, length and geometric requirements. Commonly used dimensional inspection methods include optical measurement, microscope observation and digital image processing. These inspection methods can accurately measure the dimensions of alloy wires and check for deviations or failures.

Influencing factors

The quality of ncoloy alloy wire may be affected by the following factors:

Raw material quality: The quality of alloy wire depends on the raw materials used. Ensure that raw materials meet relevant standards or specifications and have the correct chemical composition and purity. Substandard raw materials may lead to reduced performance or quality problems of the alloy wire.

Production process: The production process is crucial to the quality of alloy wire. Process parameters, such as melting temperature, extrusion/drawing temperature, cooling rate, etc., will affect the grain structure, mechanical properties and surface quality of the alloy wire. Ensure process control and optimization during production to ensure stable performance and consistent quality of alloy wire.

Heat treatment effect: Heat treatment is an important factor affecting the performance of alloy wire. Appropriate heat treatment process can improve the grain structure, strength and corrosion resistance of alloy wire. Ensure the control and correct execution of the heat treatment process to obtain the required heat treatment effect.

Testing and inspection: Quality testing and inspection are important means to ensure the quality of alloy wire. The quality characteristics of alloy wires can be detected and evaluated by using appropriate testing methods and instruments, such as chemical analysis, metallographic analysis, mechanical property testing and surface inspection. Strict testing and inspection procedures can detect and correct quality problems in a timely manner.

Quality management system: Establishing and implementing an effective quality management system is the key to ensuring the quality of alloy wire. This includes aspects such as quality control, process monitoring, records and document management, quality training, and more. Through strict quality management, the quality consistency and traceability of alloy wire can be improved.

FAQ

What is the difference between Incoloy wire and Inconel wire?

Incoloy wire and Inconel wire are both high-performance alloy wires, but their compositions are slightly different. Incoloy mainly contains nickel, iron and chromium, while Inconel contains nickel, chromium and iron with some other elements added. In addition, they differ in some performance aspects, such as corrosion resistance and high temperature performance.

How to protect Incoloy wire from corrosion?

In order to enhance the corrosion protection ability of Incoloy wire, some methods can be used, such as surface coating, electroplating, heat treatment and appropriate environmental control. In addition, proper design and use can reduce the possibility of corrosion.

Is Incoloy filament recyclable?

Yes, Incoloy filament can be recycled. Discarded Incoloy filament can be recycled and reprocessed to reduce resource waste and reduce environmental impact. Recycling also helps reduce production costs and promotes sustainability.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China