0

0

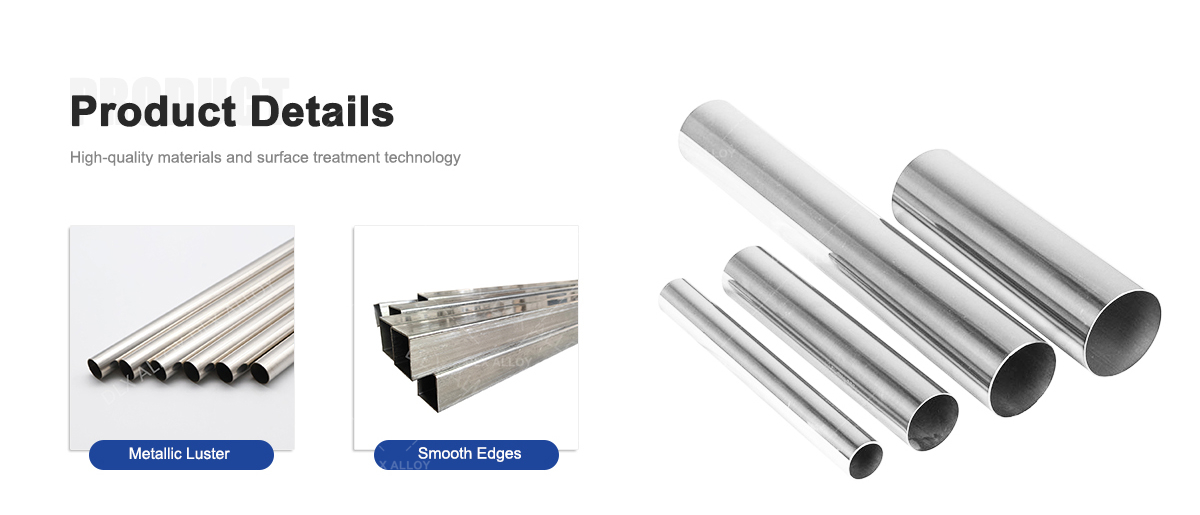

Products Description

Customized pure nickel 200 seamless pipe ni 200 nickel tube

Nickel 200 (UNS N02200) Nickel 201 (UNS N02201)

Pure nickel pipe is a high-quality pipe made of extremely pure nickel metal. It has excellent corrosion resistance, high temperature strength and thermal conductivity, making it widely used in many fields. Pure nickel pipes are widely used in pipeline systems in chemical, petroleum, natural gas and other industries, as well as in the manufacturing of key equipment in thermal power generation, aerospace, nuclear industry and other fields. Whether facing corrosive media or high-temperature environments, pure nickel pipes can provide reliable performance and long-term durability, becoming an indispensable material choice in many engineering projects.

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

CHEMICAL COMPOSITION | |||||||

Alloy | Ni+Co % | Mn % | Fe % | Si % | Cu % | C % | S % |

Nickel 201 | Min 99.2 | Max 0.35 | Max 0.4 | Max 0.35 | Max 0.25 | Max 0.02 | Max 0.01 |

Nickel 200 | Min 99 | Max 0.35 | Max 0.4 | Max 0.35 | Max 0.25 | Max 0.15 | Max 0.01 |

Physical Data | |||||

Density | Specific Heat | Electrical Resistivity | Melting Point | Thermal Conductivity | Mean Coeff Thermal Expansion |

8.89g/cm3 | 0.109(456 J/kg.℃) | 0.096×10-6ohm.m | 1435-1446℃ | 70.2 W/m-K | 13.3×10-6m/m.℃ |

High temperature resistance:

High melting point: Pure nickel has a high melting point, approximately 1455 degrees Celsius (2651 degrees Fahrenheit). This allows pure nickel tubes to maintain structural integrity in high-temperature environments without rapidly softening or melting.

Moderate coefficient of thermal expansion: Pure nickel has a moderate coefficient of thermal expansion, close to that of many structural materials in high-temperature applications, such as steel. This means that the thermal expansion of pure nickel tubes matches well with other materials at high temperatures, reducing the generation of thermal stress and thermal strain.

Oxidation resistance: Pure nickel tube has good oxidation resistance at high temperatures. It forms a dense oxide layer that prevents further oxidation reactions, thus protecting the base metal from oxygen attack. This gives pure nickel tubes a long service life in high-temperature oxidizing environments.

Metal crystal structure stability: The metal crystal structure of pure nickel is relatively stable at high temperatures and is not prone to grain boundary slippage, grain growth or structural damage. This helps maintain the strength and durability of pure nickel tubes, giving them better mechanical properties in high-temperature environments.

High-temperature strength alloys: Pure nickel can be alloyed with other metallic elements to form high-temperature strength alloys, such as nickel-based alloys. These alloys have higher strength and high temperature resistance and are widely used in pipes and equipment in high-temperature working environments, such as aerospace engines, steam turbines and petrochemical equipment.

For more details, pls directly contact us.

Influencing factors:

Temperature: Temperature is one of the most important factors. As the temperature increases, the physical and mechanical properties of pure nickel tubes will change. High temperatures can cause softening, creep and thermal expansion of the material, potentially affecting its strength and shape stability.

Oxidizing environment: Oxygen reacts with pure nickel at high temperatures to form an oxide layer. The formation rate and stability of the oxide layer will affect the oxidation resistance of pure nickel tubes. At the same time, in an oxidizing environment, other oxidation reactions may occur, such as sulfidation, carbonization, etc., which will affect the performance of pure nickel tubes.

Time: In high-temperature environments, pure nickel pipes may undergo deformation, creep, fatigue and other phenomena over time. These time-dependent effects can lead to a decrease in the strength and properties of pure nickel tubes.

Purity: The purity of pure nickel tube has an important impact on its high temperature performance. Higher purity generally means lower impurity content and better crystal structure stability, thereby improving the high-temperature strength and durability of pure nickel tubes.

Alloying elements: Pure nickel can be alloyed with other metallic elements to form high-temperature strength alloys. Adding different alloying elements can adjust the high-temperature properties of pure nickel pipes, such as improving strength, corrosion resistance, and oxidation resistance.

Processing and heat treatment: The processing and heat treatment conditions of pure nickel pipe will affect its high temperature performance. Different processing methods and heat treatment processes can change the crystal structure and phase change behavior of the material, thereby affecting its high-temperature strength and shape stability.

Q&A:

Which corrosive media are suitable for pure nickel pipes?

Pure nickel pipe has good corrosion resistance to many corrosive media, including acids, alkalis, salts, etc.

What is the high temperature resistance of pure nickel pipe?

Pure nickel tubes have good high temperature resistance and can operate stably for a long time in high temperature environments.

What is the manufacturing process of pure nickel tube?

The manufacturing process of pure nickel pipes includes hot rolling, cold rolling, cold drawing, etc.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China