0

0

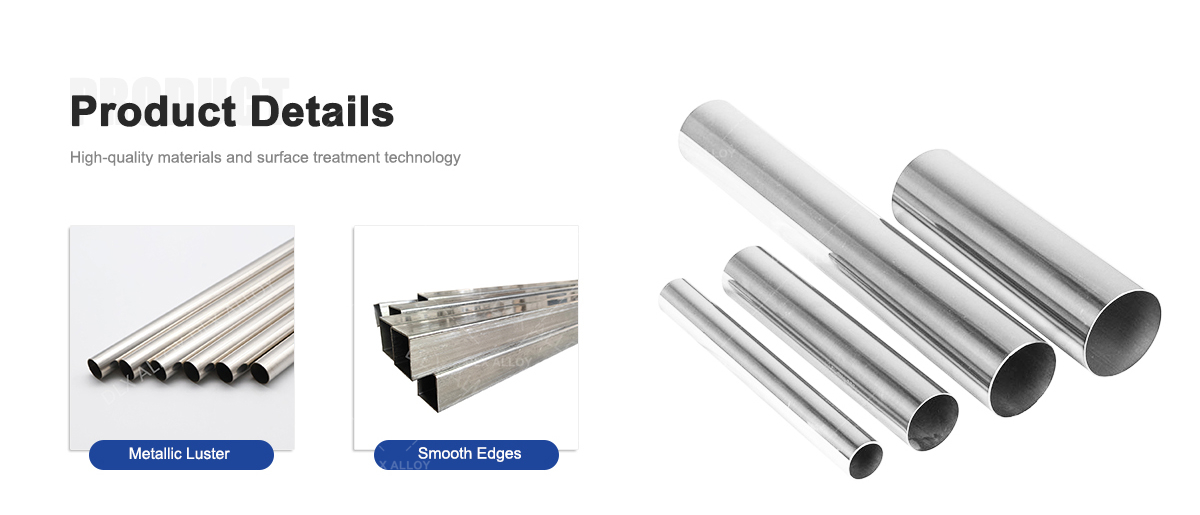

Products Description

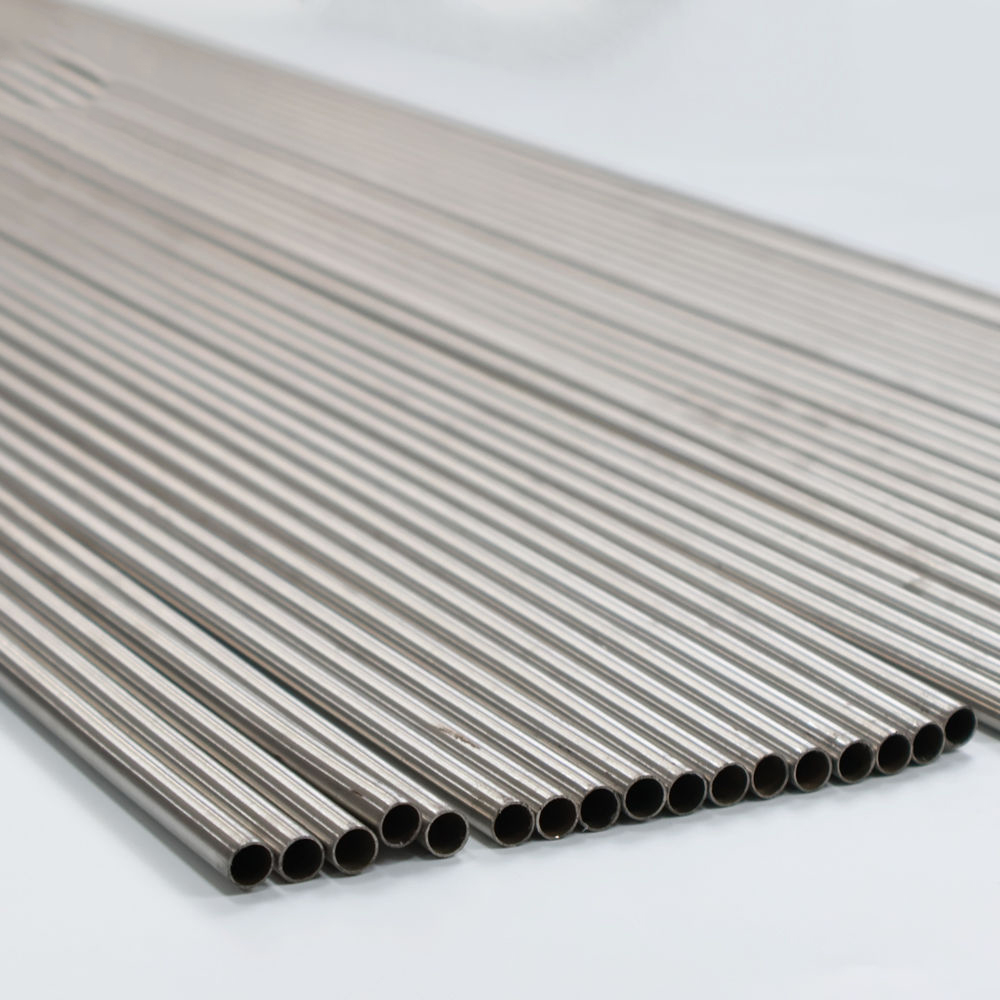

Customized pure nickel 200 seamless pipe ni 200 nickel tube

Nickel 200 (UNS N02200) Nickel 201 (UNS N02201)

Ni200 and Ni201 pure nickel pipes are pipe products made of Ni200 and Ni201 pure nickel materials. They have excellent corrosion resistance and high temperature performance and are widely used in various industries.

These pure nickel pipes can withstand the erosion of a variety of corrosive media, including acids, alkalis, salts, etc., and can still maintain stable performance in harsh environments. They exhibit good oxidation resistance and thermal stability under high temperature conditions and can withstand high temperature corrosion and thermal stress.

The process of manufacturing Ni200 and Ni201 pure nickel pipes includes hot rolling, cold rolling, cold drawing and other methods to ensure the uniformity and dimensional accuracy of the pipes. These pipes can be customized as per the customer's requirements and are available in different sizes and specifications.

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

CHEMICAL COMPOSITION | |||||||

Alloy | Ni+Co % | Mn % | Fe % | Si % | Cu % | C % | S % |

Nickel 201 | Min 99.2 | Max 0.35 | Max 0.4 | Max 0.35 | Max 0.25 | Max 0.02 | Max 0.01 |

Nickel 200 | Min 99 | Max 0.35 | Max 0.4 | Max 0.35 | Max 0.25 | Max 0.15 | Max 0.01 |

Physical Data | |||||

Density | Specific Heat | Electrical Resistivity | Melting Point | Thermal Conductivity | Mean Coeff Thermal Expansion |

8.89g/cm3 | 0.109(456 J/kg.℃) | 0.096×10-6ohm.m | 1435-1446℃ | 70.2 W/m-K | 13.3×10-6m/m.℃ |

Advantage:

First, pure nickel pipe has excellent corrosion resistance. Nickel metal itself has strong resistance to oxidation and corrosion, and can resist erosion by various corrosive media such as acids, alkalis, and salts. This makes pure nickel pipe an important pipeline material in industries such as chemical, petroleum, natural gas and offshore engineering. It is widely used in pipeline systems transporting corrosive media and various chemical equipment.

Secondly, pure nickel pipe has excellent high temperature strength and heat resistance. Nickel metal has good thermal stability and thermal conductivity, and can maintain the stability and strength of its structure in high temperature environments. Therefore, pure nickel tubes are widely used in high-temperature processes and applications, such as thermal power generation, aerospace, nuclear industry and other fields. It is used in the manufacture of burners, gas turbine components, heating elements and high-temperature heat exchangers.

In addition, pure nickel tubes also have good electrical conductivity and thermal expansion properties. This makes it widely used in electronics, electrical and thermal management fields. Pure nickel tubes can be used to manufacture battery conductive materials, electronic components, thermal components, heat pipes, etc.

For more details, pls directly contact us.

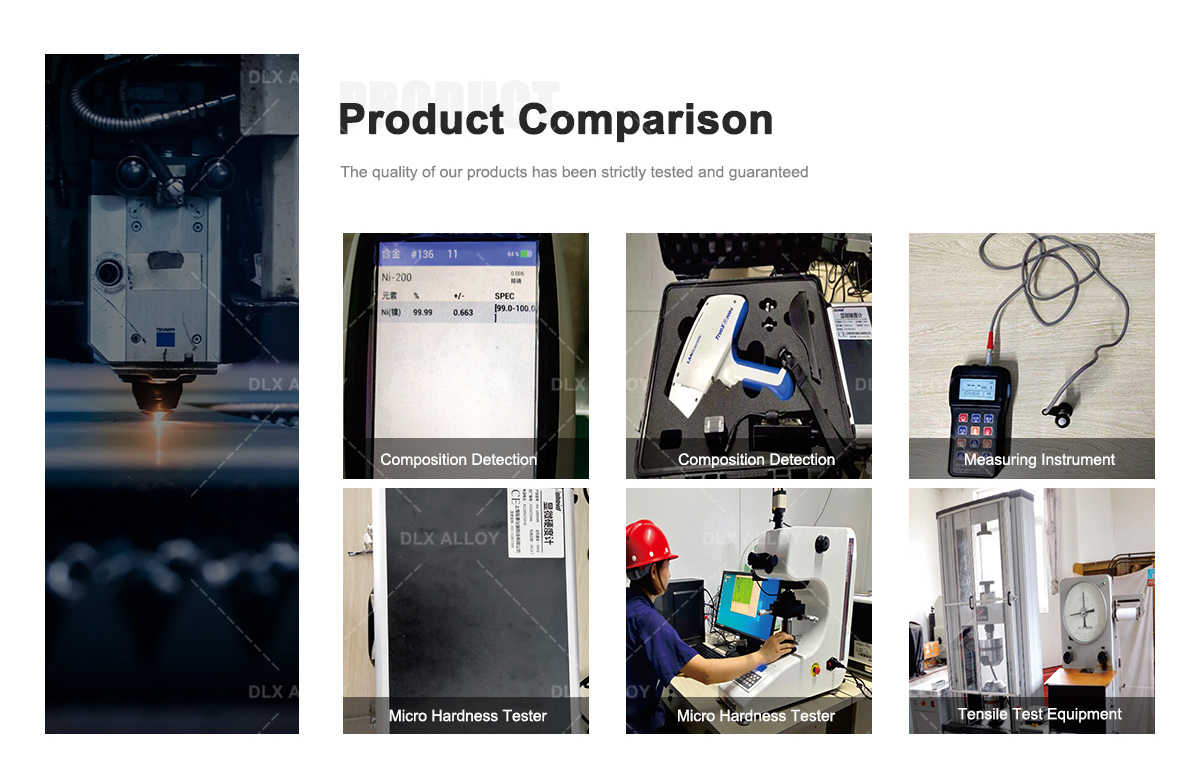

Quality Inspection:

Quality testing of pure nickel pipes is an important step in ensuring that they meet specified standards and customer requirements. The following are some common quality testing methods for pure nickel pipes:

Chemical composition analysis: The chemical composition of pure nickel tubes is detected and analyzed through chemical analysis instruments, such as spectrometers, mass spectrometers, etc. This can determine whether the content of each element in the nickel tube meets the requirements.

Physical performance testing: including testing of physical properties such as strength, hardness, extensibility, etc. Commonly used testing methods include tensile testing, impact testing, hardness testing, etc. These tests evaluate the mechanical properties and deformability of pure nickel tubes.

Metallographic microscopic analysis: Observe and analyze the microstructure of pure nickel tubes through a metallographic microscope. This can reveal the grain size, phase composition, defect status, etc. of pure nickel tubes to evaluate its material quality and processing technology.

Corrosion performance test: Corrosion performance test is performed to evaluate the corrosion resistance of pure nickel pipe under different environmental conditions. Common test methods include salt spray test, acid-base corrosion test, etc.

Dimensional and surface quality inspection: Measure the outer diameter, wall thickness, length and other dimensions of pure nickel pipes to ensure that they meet the specified requirements. At the same time, the surface quality of pure nickel pipes is inspected, including appearance, flatness, surface defects, etc.

Non-destructive testing: Use non-destructive testing methods, such as ultrasonic testing, magnetic particle testing, eddy current testing, etc., to detect internal and surface defects of pure nickel pipes to evaluate their quality status.

Pressure test: Perform a pressure test on pure nickel pipe to evaluate its pressure resistance and sealing performance. This includes pressure burst testing, air tightness testing, etc.

Q&A:

How is the weldability of pure nickel pipe?

Pure nickel pipes have good weldability and can be connected using conventional welding methods.

Are pure nickel pipes used in the petroleum industry?

Yes, pure nickel pipes are commonly used in the petroleum industry to manufacture oil drilling equipment, refining equipment, etc.

What are the surface finish requirements for pure nickel pipes?

Surface finish requirements for pure nickel tubes are usually specified based on specific application needs and can have different requirements levels.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China