0

0

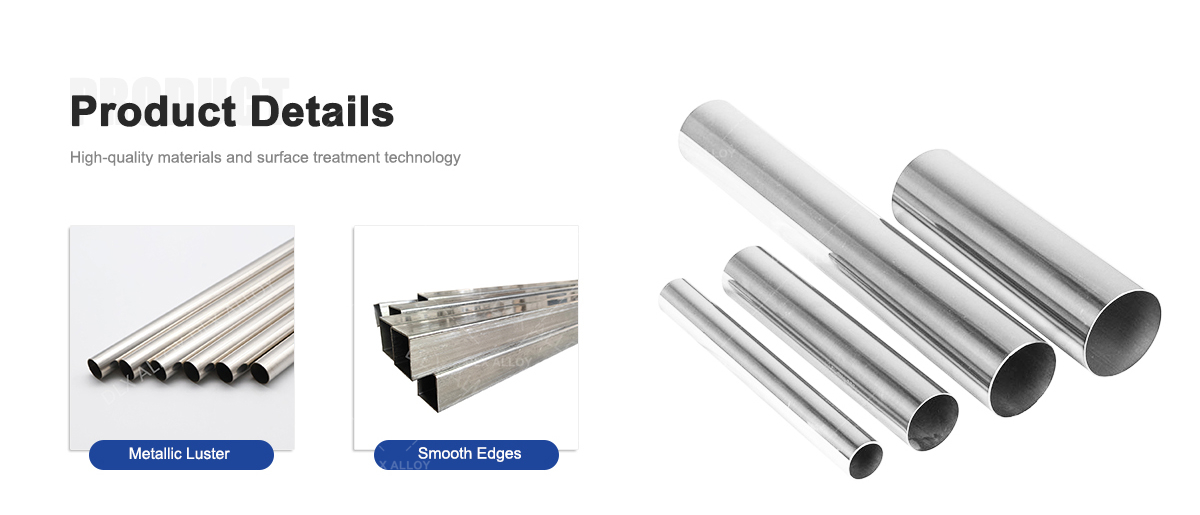

Products Description

Customized pure nickel 200 seamless pipe ni 200 nickel tube

Nickel 200 (UNS N02200) Nickel 201 (UNS N02201)

Pure nickel tubes are made of high-purity nickel material and have excellent corrosion resistance and high temperature performance. It is widely used in chemical industry, petroleum, electric power, aerospace and other fields. It can safely transport various corrosive media and maintain long-term stable operation in high temperature environments. Manufacturing processes include hot rolling, cold rolling, cold drawing, etc., with a wide range of sizes and can be customized according to customer needs. Pure nickel pipes can be surface treated by pickling, sandblasting, polishing, etc., and have various connection methods, including welding, threaded connections, and flange connections. Commonly used standards include ASTM B161, ASTM B163, ASTM B829, etc. Pure nickel pipe has excellent corrosion resistance, high temperature performance and weldability, and is widely used in aerospace, nuclear industry, petroleum industry and other fields.

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

CHEMICAL COMPOSITION | |||||||

Alloy | Ni+Co % | Mn % | Fe % | Si % | Cu % | C % | S % |

Nickel 201 | Min 99.2 | Max 0.35 | Max 0.4 | Max 0.35 | Max 0.25 | Max 0.02 | Max 0.01 |

Nickel 200 | Min 99 | Max 0.35 | Max 0.4 | Max 0.35 | Max 0.25 | Max 0.15 | Max 0.01 |

Physical Data | |||||

Density | Specific Heat | Electrical Resistivity | Melting Point | Thermal Conductivity | Mean Coeff Thermal Expansion |

8.89g/cm3 | 0.109(456 J/kg.℃) | 0.096×10-6ohm.m | 1435-1446℃ | 70.2 W/m-K | 13.3×10-6m/m.℃ |

Processability:

Pure nickel pipe is a tubular product made of pure nickel material. Pure nickel has good processability and thermal stability, so pure nickel pipes are widely used in many industrial fields. They can be manufactured in different shapes and sizes through various processing methods, such as cold working, hot working, forging and welding. This processability makes pure nickel tubes have broad application prospects in the manufacturing field. Whether you are manufacturing complex parts or simple piping systems, pure nickel tubing can meet a variety of processing needs.

Plasticity: Pure nickel pipe has high plasticity and can be plastically deformed through cold processing (such as cold drawing, cold rolling) and hot processing (such as hot extrusion, hot rolling). This allows pure nickel pipe to adapt to various shapes and sizes, including straight pipes, bent pipes, coiled pipes, etc.

Weldability: Pure nickel pipe has good weldability and can be connected to other metal materials through various welding methods (such as TIG welding, MIG welding, resistance welding, etc.). This gives pure nickel pipe a wide range of applications in the manufacture and repair of pipes, vessels and equipment.

Machinability: Pure nickel pipe has good machinability and can be processed by mechanical cutting, milling, drilling and other methods. This allows the pure nickel pipe to be sized, holes and threaded as required.

Stampability: Pure nickel tubes have good stampability and can be mass produced and manufactured through stamping, mold forming and other methods. This enables pure nickel tubes to be widely used in automobiles, electronics, home appliances and other fields.

Forgeability: Pure nickel pipe has good forgeability and can be plastically deformed and formed through hot forging, cold forging and other methods. This allows pure nickel tubes to be useful in applications where large components and complex shapes are made.

For more details, pls directly contact us.

Influencing factors:

Material composition: The material composition of pure nickel tubes has an important impact on its processability. Impurity content, addition of alloying elements, and purity all have an impact on the material's processing properties. Higher purity pure nickel materials generally have better processability.

Crystallization state: The grain structure and grain boundaries of pure nickel tubes have an impact on their processability. Fine, uniform grains generally improve the plasticity and processability of the material.

Temperature: Processing temperature has a significant impact on the processability of pure nickel tubes. Processing within a suitable temperature range can reduce the hardness of the material and improve its plasticity, which is beneficial to deformation and deformation processing.

Machining speed: Machining speed refers to the rate of deformation imposed during machining. Higher processing speeds often lead to difficult material deformation and reduced process performance.

Processing methods and parameters: Different processing methods (such as cold working, hot working, forging, stamping, etc.) and different processing parameters (such as deformation amount, deformation rate, temperature, etc.) will have an impact on the processability of pure nickel pipes.

Surface treatment: Surface treatment of pure nickel tubes (such as pickling, polishing, plating, etc.) also plays an important role in improving the machinability and processing performance of the material.

Process control: The control and optimization of the processing process are crucial to ensure the processability of pure nickel tubes. Proper process control can reduce deformation stress and stress concentration and avoid excessive deformation and damage.

Q&A:

How to clean and maintain pure nickel pipes?

Pure nickel pipes can be cleaned using methods such as pickling or alkali cleaning, and should be maintained regularly to maintain their performance.

Can pure nickel tubes be used in low temperature environments?

Pure nickel tubes have poor low-temperature performance and are generally not suitable for low-temperature environments.

What is the price of pure nickel pipe?

The price of pure nickel tubes is affected by factors such as nickel price fluctuations and manufacturing costs, and the price is relatively high.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China