0

0

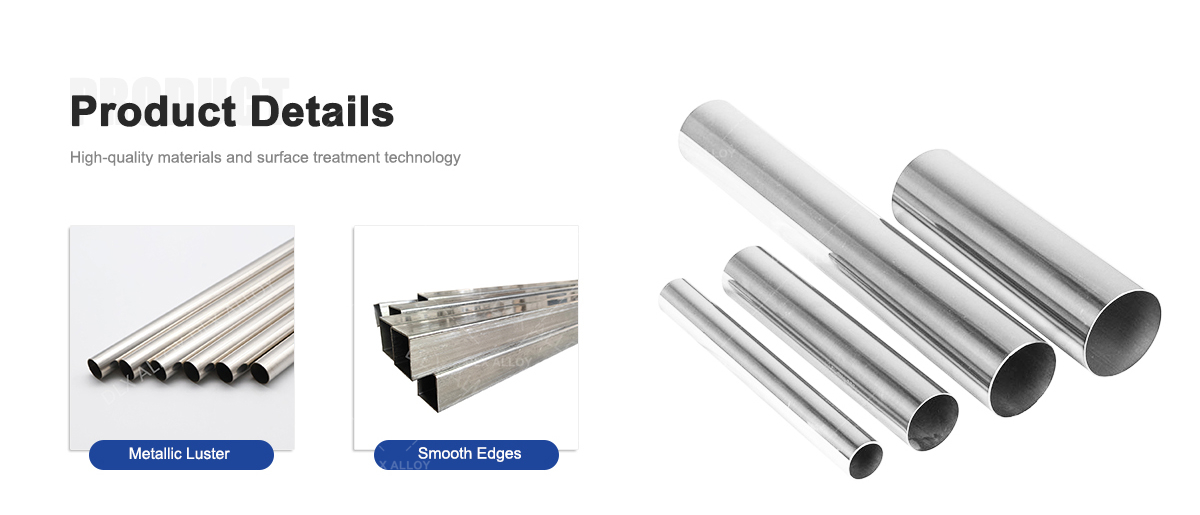

Products Description

Pure nickel pipe is a well-made pipe made of high-purity nickel metal. It has excellent corrosion resistance, high temperature strength and thermal conductivity, so it is widely used in many fields. Pure nickel pipes are used in pipeline systems in the chemical, petroleum, natural gas and other industries, as well as in the manufacturing of key equipment in thermal power generation, aerospace and electronics. Whether in corrosive environments or high temperatures, pure nickel pipes reliably provide long-lasting performance and have become one of the indispensable materials in many engineering projects.

Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

N4 | 99.9 | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

N6 | 99.5 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

Ni201 | ≥99.9 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

Ni200 | ≥99.6 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

CHEMICAL COMPOSITION | |||||||

Alloy | Ni+Co % | Mn % | Fe % | Si % | Cu % | C % | S % |

Nickel 201 | Min 99.2 | Max 0.35 | Max 0.4 | Max 0.35 | Max 0.25 | Max 0.02 | Max 0.01 |

Nickel 200 | Min 99 | Max 0.35 | Max 0.4 | Max 0.35 | Max 0.25 | Max 0.15 | Max 0.01 |

Physical Data | |||||

Density | Specific Heat | Electrical Resistivity | Melting Point | Thermal Conductivity | Mean Coeff Thermal Expansion |

8.89g/cm3 | 0.109(456 J/kg.℃) | 0.096×10-6ohm.m | 1435-1446℃ | 70.2 W/m-K | 13.3×10-6m/m.℃ |

Advantage:

Corrosion resistance: Pure nickel pipe has excellent corrosion resistance and can resist erosion by corrosive media such as acids, alkalis, and salt water. This makes it widely used in pipeline systems transporting corrosive media in the chemical, petroleum, natural gas and other industries.

High temperature strength: Pure nickel pipe has excellent high temperature strength and heat resistance, and can maintain structural stability and strength in high temperature environments. It is widely used in the manufacturing of burners, gas turbine components, heat exchangers, etc. in thermal power generation, aerospace, nuclear industry and other fields.

Thermal conductivity: Pure nickel tube has good thermal conductivity and can effectively conduct heat. This makes it widely used in the field of thermal management, such as making efficient heat exchangers and heating elements.

Mechanical properties: Pure nickel tubes have been carefully processed in the manufacturing process, have high density and excellent mechanical properties, and can withstand complex engineering environments and stress requirements.

Processability: Pure nickel pipes can be connected and processed by welding, brazing and other methods to meet different engineering needs.

For more details, pls directly contact us.

Influencing factors:

High purity: Pure nickel tubes are made of high-purity nickel metal, with very low levels of impurities and other metallic elements. High-purity nickel metal has fewer dislocations, grain boundaries and defects, thereby reducing erosion by corrosive media.

Oxide layer protection: When pure nickel tubes come into contact with oxygen, they will form a dense oxide layer, which can prevent further oxidation reactions. This oxide layer is particularly effective in high-temperature environments and can protect nickel metal from oxidation by oxygen, thereby improving corrosion resistance.

Chemical stability of nickel: Nickel has good chemical stability and is highly inert to many acids, bases, salts and other chemical substances. It resists corrosion and reaction from chemicals, thereby extending the service life of pure nickel pipes.

Alloying improvement: Pure nickel tubes can be improved through alloying to form alloy materials with other elements. Alloying can further improve the corrosion resistance of pure nickel pipes, allowing them to exhibit higher corrosion resistance in specific corrosive environments.

Related information:

Alloying improvement: Pure nickel tubes can be alloyed with other metal elements to form various alloy materials, such as nickel-chromium alloy, nickel-copper alloy, etc. These alloys can further improve the properties of pure nickel pipes, such as corrosion resistance, high temperature strength and oxidation resistance. These alloys are widely used in the manufacture of piping systems and equipment in special environments.

Manufacturing process: The manufacturing process of pure nickel pipe involves multiple process steps, such as forging, rolling, drawing and welding. These processes enable pure nickel tubes to achieve the desired size, shape and properties. Optimization of the manufacturing process can improve the quality and performance of pure nickel tubes.

Q&A:

What is pure nickel tube?

Pure nickel pipe is a tubular product made of high-purity nickel material with good corrosion resistance and high temperature performance.

What is the main use of pure nickel pipe?

Pure nickel pipes are widely used in chemical industry, petroleum, electric power, aerospace and other fields to transport corrosive media, high-temperature gases and liquids.

What is the difference between pure nickel tube and nickel alloy tube?

Pure nickel tubes are made of higher purity nickel, while nickel alloy tubes are composed of nickel and other alloying elements.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China