0

0

Products Description

thermocouple cable wire high quality KTJERSNB-type extension wires

Description

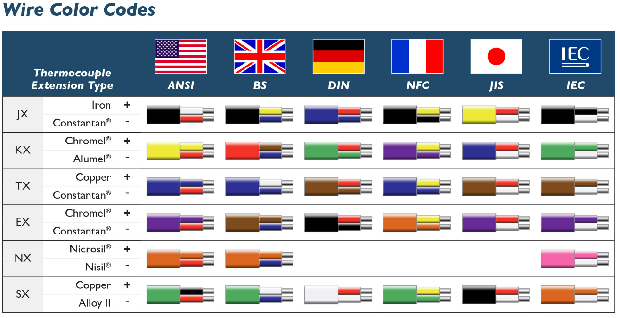

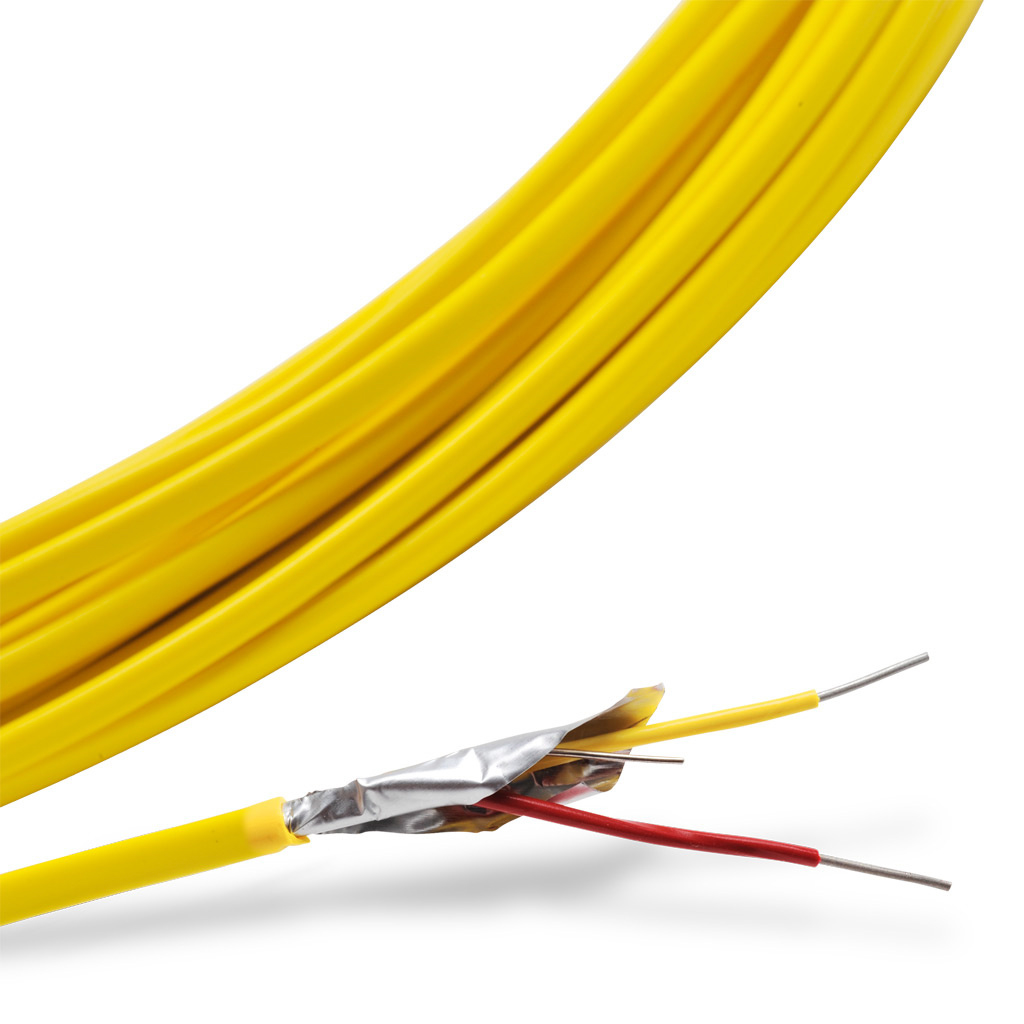

Thermocouple compensation wires play a crucial role in industrial process control. They are suitable for various types of thermocouples, such as K, N, E, J, T, B, R, and S types, each with specific temperature ranges and characteristics to meet the needs of different applications.

In industrial process control, temperature is a key parameter that affects the stability of the production process and product quality. The thermocouple compensation wire ensures the accuracy and reliability of temperature measurement by connecting the thermocouple to the temperature display instrument. Whether in high-temperature ironmaking or precision electronic equipment manufacturing, thermocouple compensation wires can provide accurate temperature measurement data, helping operators take timely measures to ensure the smooth progress of the production process.

In addition, thermocouple compensation wires also have characteristics such as high temperature resistance, anti-interference, and corrosion resistance, making them suitable for various harsh industrial environments. They can be used to monitor various scenarios such as furnace temperature, pipeline temperature, and equipment temperature, providing important data support and guarantee for industrial production.

Products parameter

K-type compensating wire

Material: Nickel chromium nickel silicon alloy

Temperature range: -200 ℃ to 1300 ℃

Application: Widely used for temperature monitoring in industrial furnaces, pipelines, and reactors in oxidizing and inert atmospheres.

N-type compensating wire

Material: nickel chromium silicon nickel silicon alloy

Temperature range: -200 ℃ to 1300 ℃

Application: Suitable for chemical, petroleum, and food processing industries that require high precision and stability.

E-type compensating wire

Material: nickel chromium copper nickel alloy

Temperature range: -200 ℃ to 900 ℃

Application: Suitable for high-precision temperature measurement, such as laboratory equipment and medical equipment.

J-shaped compensating wire

Material: Iron copper nickel alloy

Temperature range: -200 ℃ to 1200 ℃

Application: Suitable for temperature monitoring of general industrial furnaces and boilers.

T-shaped compensating wire

Material: Copper Copper Nickel Alloy

Temperature range: -200 ℃ to 350 ℃

Application: Especially suitable for temperature control in low-temperature environments, such as refrigeration and freezing equipment.

B-type, R-type, S-type compensating wires

Material: Platinum rhodium alloy

Temperature range: up to 1600 ℃ to 1800 ℃

Application: Mainly used for scientific research and high-end industrial process control, as well as temperature measurement in special occasions.

Code | Wire Component of the thermocouple | ||

+Positive leg | - Negative Leg | ||

N | Ni-Cr-Si(NP) | Ni-Si-magnesium (NN) | |

K | Ni-Cr(KP) | Ni-Al(Si) (KN) | |

E | Ni-Cr(EP) | Cu-Ni (EN) | |

J | Iron (JP) | Cu-Ni (JN) | |

T | Copper (TP) | Cu-Ni (TN) | |

B | Platinum Rhodium-30% | Platinum Rhodium -6% | |

R | Platinum Rhodium-13% | Platinum | |

S | Platinum Rhodium -10% | Platinum | |

Calibration of thermocouple | Model number of Compensation cable | Alloy wire name of Compensation cable |

S or R | SC or RC | Cu-CuNi |

K | KC | Cu-CuNi |

KX | NiCr-NiSi | |

N | NC | Fe-CuNi |

NX | NiCrSi-NiSiMg | |

E | EX | NiCr-CuNi |

J | JX | Fe-CuNi |

T | TX | Cu-CuNi |

Isulation | PTFE | PFA | TEF | FEP | PVC | FG | Silicone | Quartz Fiber |

Max temp (℃) | 260 | 260 | 200 | 200 | 108 | 400 | 200 | 800 |

characteristic

Accurate matching: Each type of compensating wire is precisely matched with a specific type of thermocouple, ensuring consistent thermoelectric potential throughout the entire temperature range.

Wide temperature range: Different types of compensation wires are suitable for different temperature ranges, ranging from -200 ℃ to 1800 ℃, meeting diverse industrial needs.

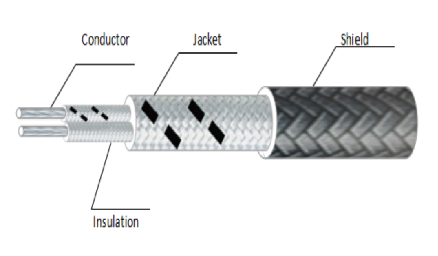

Anti interference capability: Shielded compensation wires can effectively resist electromagnetic interference, ensuring signal stability and accuracy.

Corrosion resistance and wear resistance: High quality materials such as fluoroplastics are used to ensure the durability of the wires in harsh environments.

Easy to install and maintain: The design is simple, making it easy for on-site installation and later maintenance.

International standards: Adhere to international standards such as IEC584-3 to ensure product quality and reliability.

Specific applications in industrial process control

Chemical industry: Compensation wires are used to precisely control the temperature of chemical reactions, ensuring product quality and production efficiency.

Chemical industry: Compensation wires are used to precisely control the temperature of chemical reactions, ensuring product quality and production efficiency.

Power industry: Monitor the temperature of boilers and steam pipelines in power plants to prevent equipment overheating and malfunctions.

Oil and natural gas: Monitor high-temperature equipment during drilling and refining processes to ensure process safety and efficiency.

Metallurgical industry: Monitor the temperature of blast furnaces and rolling mills in steel production to optimize the production process.

Food processing: Control temperature during cooking, baking, and refrigeration to ensure food safety and quality.

Pharmaceutical industry: Monitoring temperature during drug production and storage to ensure the stability and effectiveness of drugs.

Environmental monitoring: monitoring indoor and outdoor temperatures in climate and environmental research, providing accurate data support.

Research experiment: Accurate temperature control and measurement in the laboratory to support scientific research.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China