0

0

Products Description

Description

Thermocouple compensation wires play an important role in food processing and production. Temperature control during food processing is crucial for ensuring product quality, safety, and hygiene standards. Various types of thermocouple compensation wires (including K, N, E, J, T, B, R, and S types) are widely used in food processing production lines to ensure accurate temperature control and monitoring of food during processing.

In food processing, temperature control directly affects the taste, texture, color, as well as the growth and reproduction of microorganisms of the product. The thermocouple compensation wire connects the thermocouple to the temperature monitoring equipment, which can timely and accurately reflect the temperature changes during the processing, thereby helping producers ensure that the product meets safety standards and quality requirements.

Whether in cooking, baking, sterilization, freezing, or insulation, thermocouple compensation wires can provide reliable temperature measurement data. They have characteristics such as high temperature resistance, corrosion resistance, and anti-interference, and are suitable for various food processing environments and conditions.

In addition, thermocouple compensation wires can also be integrated with automated control systems to achieve automated monitoring and adjustment of the processing process, improving production efficiency and product consistency.

Products parameter

Code | Wire Component of the thermocouple | ||

+Positive leg | - Negative Leg | ||

N | Ni-Cr-Si(NP) | Ni-Si-magnesium (NN) | |

K | Ni-Cr(KP) | Ni-Al(Si) (KN) | |

E | Ni-Cr(EP) | Cu-Ni (EN) | |

J | Iron (JP) | Cu-Ni (JN) | |

T | Copper (TP) | Cu-Ni (TN) | |

B | Platinum Rhodium-30% | Platinum Rhodium -6% | |

R | Platinum Rhodium-13% | Platinum | |

S | Platinum Rhodium -10% | Platinum | |

Calibration of thermocouple | Model number of Compensation cable | Alloy wire name of Compensation cable |

S or R | SC or RC | Cu-CuNi |

K | KC | Cu-CuNi |

KX | NiCr-NiSi | |

N | NC | Fe-CuNi |

NX | NiCrSi-NiSiMg | |

E | EX | NiCr-CuNi |

J | JX | Fe-CuNi |

T | TX | Cu-CuNi |

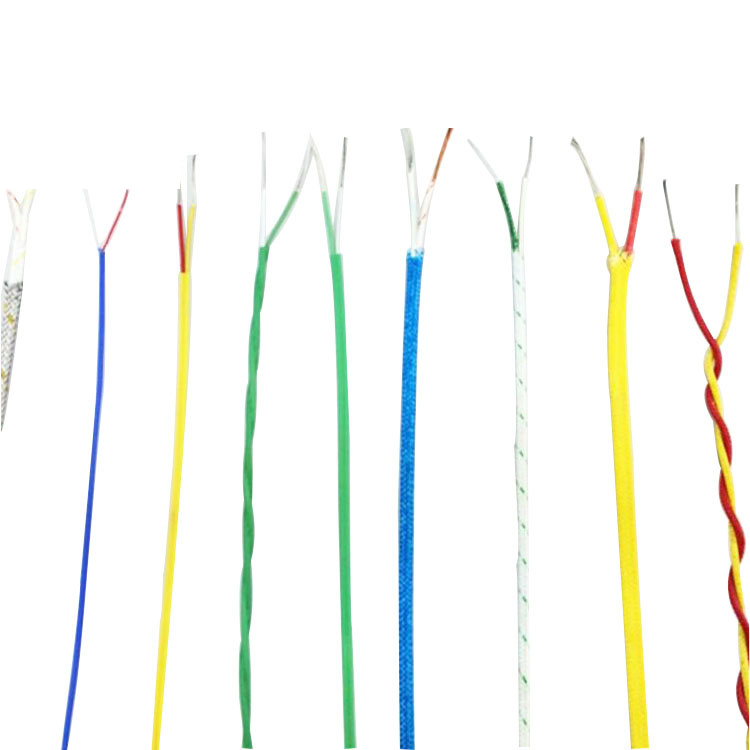

Isulation | PTFE | PFA | TEF | FEP | PVC | FG | Silicone | Quartz Fiber |

Max temp (℃) | 260 | 260 | 200 | 200 | 108 | 400 | 200 | 800 |

characteristic

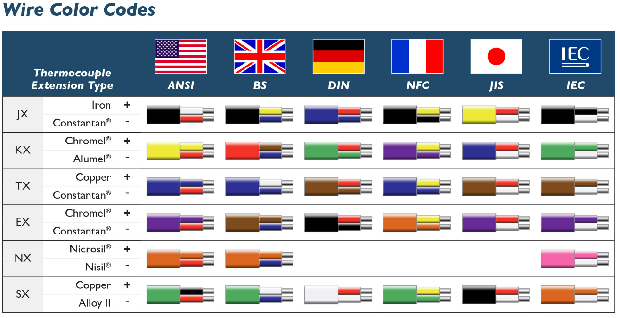

Accurate matching: Different types of compensation wires are precisely matched with corresponding types of thermocouples to ensure the accuracy of temperature measurement.

Wide temperature range: suitable for various food processing environments from low-temperature refrigeration to high-temperature cooking.

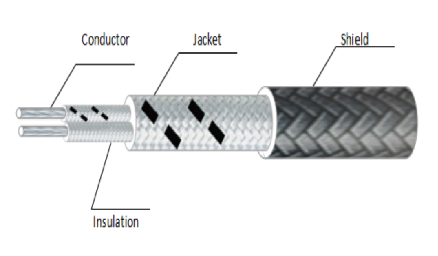

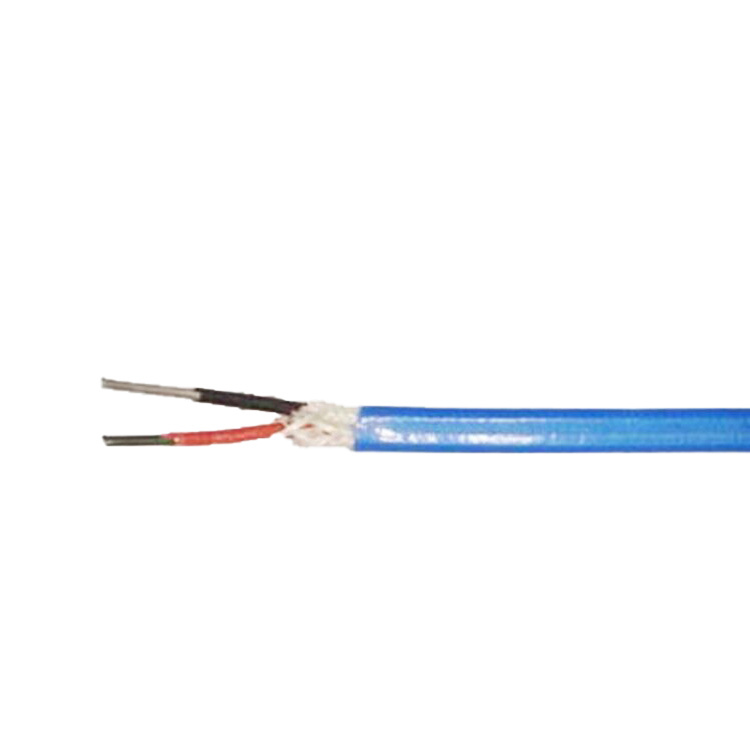

Anti interference capability: Shielded compensation wires can effectively resist electromagnetic interference and ensure signal stability.

Corrosion resistance and wear resistance: Made of corrosion-resistant materials, suitable for use in humid and chemical environments.

Easy to install and maintain: The design is simple and easy to install and maintain in food processing environments.

Specific application aspects in food processing and production

Baking process: Monitor and control the temperature inside the oven to ensure even baking.

Cooking process: Real time monitoring of cooking equipment temperature to ensure food cooking quality.

Refrigeration and freezing: Monitor the temperature of the refrigeration and freezing warehouses to ensure safe food storage.

Sterilization process: In the high-temperature sterilization process of food, control and monitor the temperature to ensure the sterilization effect.

Quality control: Monitor the temperature of key points on the production line to ensure that the product meets quality standards.

Related Q&A

Q: Why is thermocouple compensation wire important in food processing?

Answer: Thermocouple compensation wires ensure accurate temperature measurement during food processing, which is crucial for ensuring food safety and quality.

Q: How to choose the appropriate thermocouple compensation wire?

Answer: Select the corresponding type of compensation wire based on the temperature range, environmental conditions, and measurement accuracy required in the food processing process.

Q: How can thermocouple compensation wires help improve the efficiency of food processing?

Answer: By providing accurate temperature control, thermocouple compensation wires can help optimize the machining process, reduce energy waste, and improve production efficiency.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China