0

0

Products Description

J E N k type thermocouple extension wire Thermocouple K thermocouple J cable

Description

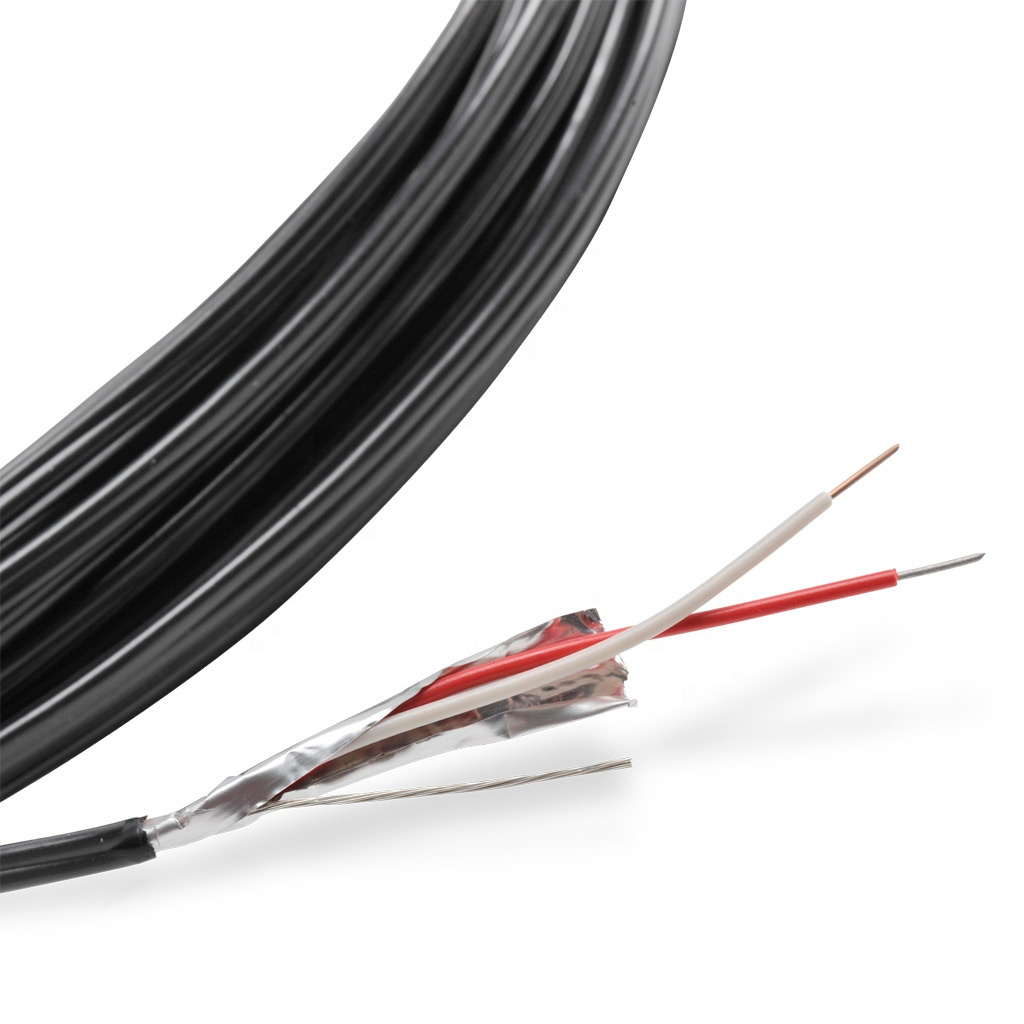

Thermocouple compensation wire is a type of wire specially designed to be used in conjunction with thermocouples. It can extend the cold end of thermocouples to measurement or control equipment while maintaining the same thermoelectric potential as thermocouples to compensate for errors caused by temperature changes. Thermocouple compensation wires have critical applications in the heat treatment process. Accurate temperature control is crucial for the quality and performance of products in heat treatment processes such as metal processing, quenching, annealing, and welding. Various types of thermocouple compensation wires (including K, N, E, J, T, B, R, and S types) are widely used in these processes to ensure the accuracy and reliability of temperature measurement.

Accurate temperature control during heat treatment can affect key properties such as crystal structure, hardness, and strength of materials. The thermocouple compensation wire connects the thermocouple to the temperature display instrument, eliminating errors caused by the connection circuit and ensuring the accuracy of temperature measurement. This allows operators to adjust based on real-time temperature data, ensuring that the temperature during the heat treatment process meets the design requirements, thereby achieving ideal material properties.

In addition, thermocouple compensation wires also have characteristics such as high temperature resistance and corrosion resistance, making them suitable for various heat treatment environments. Whether in metal production workshops or laboratories, these wires can reliably provide temperature monitoring and control functions, providing important support for the smooth progress of heat treatment processes.

Products parameter

Code | Wire Component of the thermocouple | ||

+Positive leg | - Negative Leg | ||

N | Ni-Cr-Si(NP) | Ni-Si-magnesium (NN) | |

K | Ni-Cr(KP) | Ni-Al(Si) (KN) | |

E | Ni-Cr(EP) | Cu-Ni (EN) | |

J | Iron (JP) | Cu-Ni (JN) | |

T | Copper (TP) | Cu-Ni (TN) | |

B | Platinum Rhodium-30% | Platinum Rhodium -6% | |

R | Platinum Rhodium-13% | Platinum | |

S | Platinum Rhodium -10% | Platinum | |

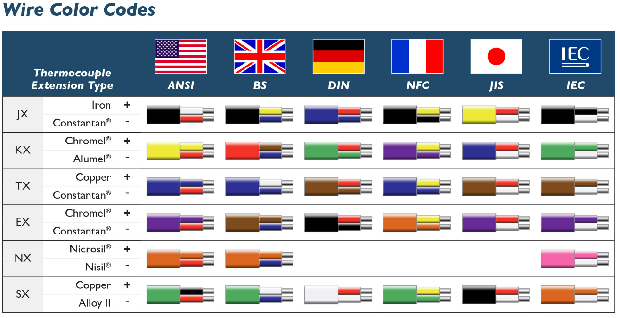

Calibration of thermocouple | Model number of Compensation cable | Alloy wire name of Compensation cable |

S or R | SC or RC | Cu-CuNi |

K | KC | Cu-CuNi |

KX | NiCr-NiSi | |

N | NC | Fe-CuNi |

NX | NiCrSi-NiSiMg | |

E | EX | NiCr-CuNi |

J | JX | Fe-CuNi |

T | TX | Cu-CuNi |

Isulation | PTFE | PFA | TEF | FEP | PVC | FG | Silicone | Quartz Fiber |

Max temp (℃) | 260 | 260 | 200 | 200 | 108 | 400 | 200 | 800 |

characteristic

Wide temperature range: Different types of compensation wires are suitable for different temperature ranges, meeting the needs of high-temperature measurement during heat treatment.

Accurate matching: Each type of compensation wire is precisely matched with the corresponding type of thermocouple, ensuring consistent thermoelectric potential throughout the entire measurement temperature range.

Corrosion resistance and wear resistance: High quality materials such as fluoroplastics are used to ensure the durability of wires in high temperature and corrosive environments.

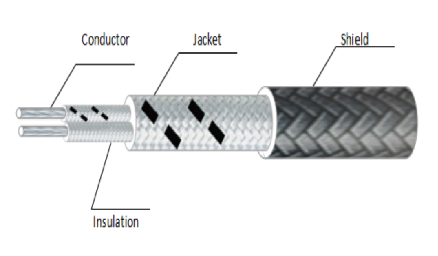

Anti interference capability: Shielded compensation wires can effectively resist electromagnetic interference, ensuring signal stability and accuracy.

Easy to install and maintain: The design is simple, making it easy for on-site installation and later maintenance.

Specific applications in heat treatment processes

Accurate control: During the heat treatment process, compensating wires ensure the accuracy of temperature data measured by thermocouples, thereby achieving precise temperature control.

Improving product quality: By precise temperature control and compensating wires, the performance and quality of metal products after heat treatment can be improved.

Energy saving and consumption reduction: Accurate temperature measurement and control help optimize the heat treatment process, reduce energy consumption and production costs.

Equipment protection: During high-temperature heat treatment, compensating wires help to monitor and prevent equipment overheating, extending the service life of the equipment.

Data recording: The compensating wire can be used in conjunction with a data recorder to record temperature changes during the heat treatment process, facilitating quality tracking and process optimization.

Safety guarantee: In high-temperature and potentially hazardous heat treatment environments, compensating wires provide a safe temperature measurement method.

Q&A

Q: What is the main function of thermocouple compensation wires?

Answer: The main function of thermocouple compensation wire is to extend the cold end of the thermocouple to the control equipment, maintain the same thermoelectric potential as the thermocouple, to compensate for errors caused by temperature changes, and ensure the accuracy of temperature measurement.

Q: How to choose the appropriate compensation wire for a specific heat treatment process?

Answer: Choosing the appropriate compensation wire should consider the required temperature range, environmental conditions (such as corrosive gases), and the required measurement accuracy. For example, the K-type is suitable for a wide range of applications from -200 ℃ to 1300 ℃, while the S-type is suitable for extreme high temperature environments up to 1600 ℃.

Q: What are the benefits of using compensating wires for the heat treatment process?

Answer: The use of compensating wires can improve the temperature control accuracy of the heat treatment process, reduce energy waste, improve product quality, extend equipment life, and enhance operational safety.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China