0

0

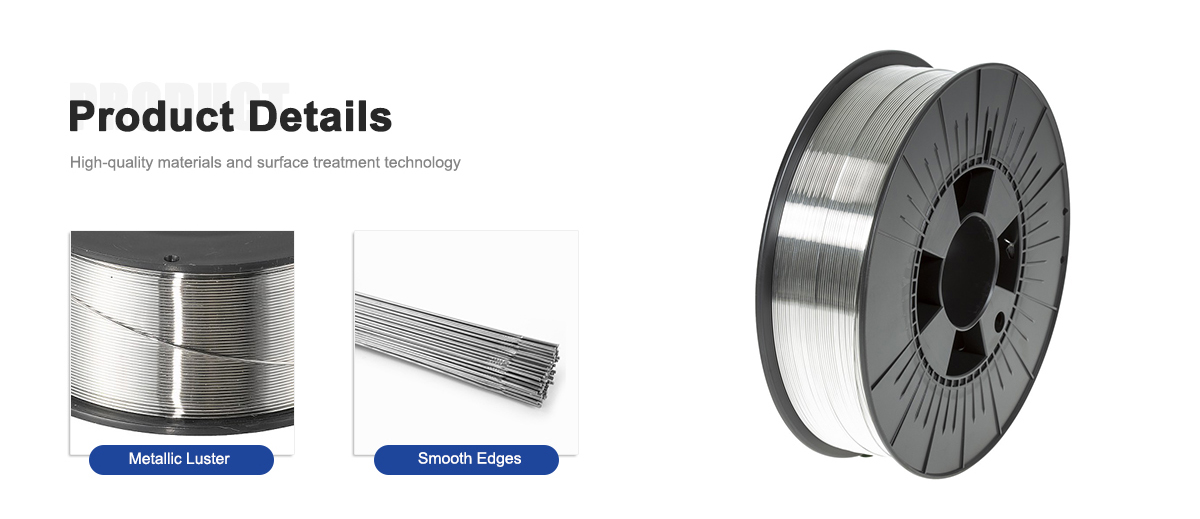

Products Description

Nickel based Inconel 625 welding wire ENiCrMo-3 has good resistance to corrosion and high temperature,and has high strength and good fabricability.it is widely used in petrochemical, metallurgy, atomic energy, ocean development, aviation, aerospace and other industries.

Welding series:

ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1, ER70S-6.

Standard: Conforms to Certification AWS A5.14 ASME SFA A5.14

Size: 0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM / 5.0MM

Form: MIG(15kgs/spool), TIG(5kgs/box),Strip

Advantages

Welding rod / Welding Electrode Advantages:

1. Stable arc, less splash

2. Shaped good appearance

3. Easy for removal of slag layer

4. Easy for striking arc and restriking arc

5. Operable with low amperages on sheet metal

6. Slag control accommodates vertical down welding

Item | ERNiCrMo-3 | ERNiCrMo-4 | ERNiCrMo-13 | ERNiCrFe-7 | ERNiCr-3 | ERNiCu-7 | ERCuNi | ERNi-1 |

C | 0.1 | 0.02 | 0.01 | 0.04 | 0.1 | 0.15 | 0.03 | 0.15 |

Mn | 0.05 | 1 | 0.5 | 1 | 2.5-3.5 | 4 | 0.5-1.0 | 1 |

Fe | 5 | 4-7 | 1.5 | 7-11 | 3 | 2.5 | 0.65 | 1 |

P | 0.02 | 0.04 | 0.015 | 0.02 | 0.03 | 0.02 | 0.01 | 0.03 |

S | 0.015 | 0.03 | 0.005 | 0.015 | 0.015 | 0.015 | 0.01 | 0.015 |

Si | 0.05 | 0.08 | 0.1 | 0.5 | 0.5 | 1.25 | 0.15 | 0.75 |

Cu | 0.5 | 0.5 | N/A | 0.3 | 0.5 | rest | rest | 0.25 |

Ni | ≥58 | rest | rest | rest | ≥67 | 62-69 | 30-32 | ≥93 |

Co | N/A | 2.5 | 0.3 | N/A | N/A | N/A | N/A | N/A |

Al | 0.4 | N/A | 0.1-0.4 | 1.1 | N/A | 1.25 | 0.15 | 1.5 |

Ti | 0.4 | N/A | N/A | 1 | 0.75 | 1.5-3 | 0.5 | 2-3.5 |

Cr | 20-23 | 14.5-16.5 | 22-24 | 28.5-31 | 18.0-22.0 | N/A | N/A | N/A |

Nb+Ta | 3.5-4.15 | N/A | 1.8-2.5 | 0.01 | 2.0-3.0 | N/A | N/A | N/A |

Mo | 8.0-10 | 15-17 | 15-16 | 0.5 | N/A | N/A | N/A | N/A |

V | N/A | 0.35 | N/A | N/A | N/A | N/A | N/A | N/A |

W | N/A | 3.0-4.5 | N/A | N/A | N/A | N/A | N/A | N/A |

Rest | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 |

Nickel and Nickel Alloy Welding Wire | |

Product Model (AWS) | Application |

ERNiCr-3 | For welding 600, 601 and 800 alloys themselves, and welding dissimilar steels between stainless steel and carbon steel ERNiCrFe-7; For welding Inconel alloys within ASTM B163, 166, 167 and 168 |

ERNiCrFe-6 | For welding of steel and Inconel, welding of steel and stainless steel and nickel-based alloys |

ERNiCrCoMo-1 | Dissimilar welding for welding nickel-chromium-cobalt-molybdenum alloys and various superalloys |

ERNiCrMo-3 | It is used for welding of nickel alloy, carbon steel, stainless steel and low alloy steel, mainly used for welding of 625, 601, 802 alloy and welding of 9% nickel alloy |

ERNi-CI | Industrial pure nickel for welding malleable and grey cast iron |

ERCuNi | For welding of 70/30, 80/20, 90/10 copper-nickel alloys |

ERNiCu-7 | For welding nickel copper alloys B127, 163, 164 and 165 etc. |

ERNi-1 | For welding of pure nickel castings and forgings such as alloys within ASTM B160, 161, 162, 163 |

ERNiFeMn-CI | For welding of nodular cast iron, ductile iron, malleable cast iron and grey cast iron to itself or to stainless steel, carbon steel, low alloy steel and various nickel alloys |

ERNiCrMo-4 | For welding nickel-chromium-molybdenum alloy itself, or welding nickel-chromium-molybdenum alloy and steel and most other nickel-based alloys |

ERNiCrMo-11 | It is used for welding of nickel-chromium-molybdenum alloy itself, or welding of nickel-chromium-molybdenum alloy and steel and most other nickel-based alloys, and can also be used for surfacing welding of nickel-chromium-molybdenum alloy and steel welding seam |

ERNiCrMo-13 | For welding low carbon nickel chromium molybdenum alloys |

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China