0

0

Products Description

ERNiCrMo-3 is a welding material that is a nickel-based alloy commonly used in welding applications in high temperature and corrosive environments. The chemical composition of the material includes elements such as nickel (Ni), chromium (Cr), and molybdenum (Mo).

ERNiCrMo-3 material has excellent corrosion resistance and high temperature performance, so it is widely used in welding processes in petrochemical, aerospace, nuclear industry and other fields. It can be used to weld high-alloy steel, nickel-based alloys, stainless steel and other materials, as well as various corrosion-resistant materials.

ERNiCrMo-3 welding wire is commonly used in gas shielded welding (TIG welding) and arc welding (MIG/MAG welding), providing stable welding performance and good deposited metal quality. The material has good oxidation resistance and high strength in high temperature environments, and can withstand mechanical and chemical stress at high temperatures.

Overall, ERNiCrMo-3 is a high-performance welding material suitable for engineering applications requiring corrosion resistance and high-temperature performance.

Welding series:

ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1, ER70S-6.

Standard: Conforms to Certification AWS A5.14 ASME SFA A5.14

Size: 0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM / 5.0MM

Form: MIG(15kgs/spool), TIG(5kgs/box),Strip

ERNiCrMo-3

C | Cr | Cu | Fe | Mn | Mo | Ni | P | Si | S | Ti | Nb+Ta | Co | Al | V | W | Rest |

0.1 | 20-23 | 0.5 | 5 | 0.05 | 8.0-10 | ≥58 | 0.02 | 0.05 | 0.015 | 0.4 | 3.5-4.15 | N/A | 0.4 | N/A | N/A | ≤0.50 |

Nickel and Nickel Alloy Welding Wire | |

Product Model (AWS) | Application |

ERNiCr-3 | For welding 600, 601 and 800 alloys themselves, and welding dissimilar steels between stainless steel and carbon steel ERNiCrFe-7; For welding Inconel alloys within ASTM B163, 166, 167 and 168 |

ERNiCrFe-6 | For welding of steel and Inconel, welding of steel and stainless steel and nickel-based alloys |

ERNiCrCoMo-1 | Dissimilar welding for welding nickel-chromium-cobalt-molybdenum alloys and various superalloys |

ERNiCrMo-3 | It is used for welding of nickel alloy, carbon steel, stainless steel and low alloy steel, mainly used for welding of 625, 601, 802 alloy and welding of 9% nickel alloy |

ERNi-CI | Industrial pure nickel for welding malleable and grey cast iron |

ERCuNi | For welding of 70/30, 80/20, 90/10 copper-nickel alloys |

ERNiCu-7 | For welding nickel copper alloys B127, 163, 164 and 165 etc. |

ERNi-1 | For welding of pure nickel castings and forgings such as alloys within ASTM B160, 161, 162, 163 |

ERNiFeMn-CI | For welding of nodular cast iron, ductile iron, malleable cast iron and grey cast iron to itself or to stainless steel, carbon steel, low alloy steel and various nickel alloys |

ERNiCrMo-4 | For welding nickel-chromium-molybdenum alloy itself, or welding nickel-chromium-molybdenum alloy and steel and most other nickel-based alloys |

ERNiCrMo-11 | It is used for welding of nickel-chromium-molybdenum alloy itself, or welding of nickel-chromium-molybdenum alloy and steel and most other nickel-based alloys, and can also be used for surfacing welding of nickel-chromium-molybdenum alloy and steel welding seam |

ERNiCrMo-13 | For welding low carbon nickel chromium molybdenum alloys |

Compared

ErNiCrMo-3 welding wire has some obvious advantages and characteristics compared with other materials in oil pipeline welding:

1. Corrosion resistance: Compared with ordinary carbon steel welding wire, ErNiCrMo-3 welding wire has higher corrosion resistance and can resist the erosion of corrosive gases and liquids such as hydrogen sulfide, extending the service life of the pipeline.

2. High-temperature strength: ErNiCrMo-3 welding wire has high high-temperature strength and can maintain stable welding performance under high-temperature conditions. It is suitable for pipeline systems that transport high-temperature crude oil or operate in high-temperature environments.

3. Resistance to stress corrosion cracking: ErNiCrMo-3 welding wire has good resistance to stress corrosion cracking, which is particularly important in the welding of oil pipelines because pipeline systems are often affected by complex stresses from geological stresses and operating conditions.

4. Welding quality: ErNiCrMo-3 welding wire has good fluidity and stability, and can form strong and sealed welds, ensuring welding quality and safe operation of pipelines.

5. Multi-material compatibility: ErNiCrMo-3 welding wire is compatible with various materials and is suitable for welding between different materials, improving flexibility and applicability.

In comparison, ordinary carbon steel welding wire may not perform well in terms of corrosion resistance and high temperature strength, and is prone to problems such as corrosion, deformation or cracking, but ErNiCrMo-3 welding wire is more widely used in oil pipeline welding to Ensure the safe, reliable and long-lasting operation of the pipeline system.

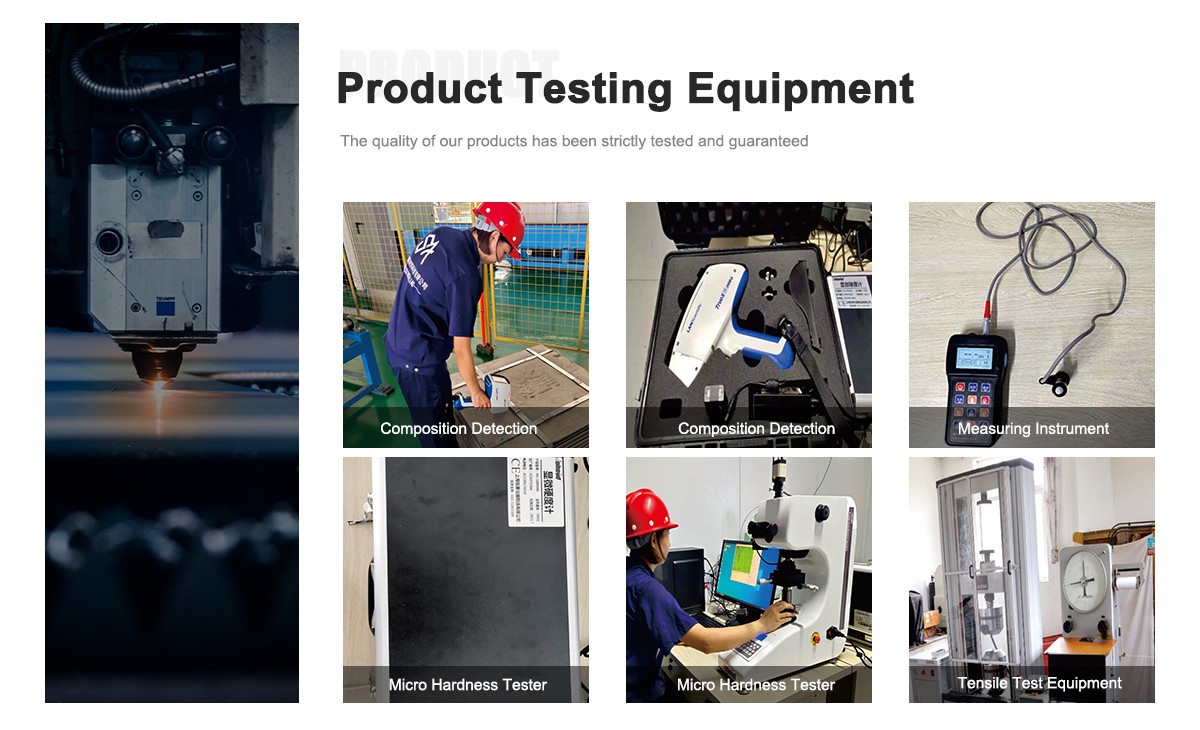

Detection

The quality inspection of ERNiCrMo-3 welding wire usually includes the following aspects:

Chemical composition analysis: Conduct chemical composition analysis on welding wire samples to ensure that the welding wire meets the specified composition requirements. This can be done by spectroscopic or chemical analysis methods.

Diameter and visual inspection: Measure the diameter of the welding wire to ensure it meets specified dimensional requirements. At the same time, check whether the appearance of the welding wire is flat and smooth, with no obvious defects or damage.

Mechanical property testing: Evaluate the mechanical properties of the welding wire, such as tensile strength, yield strength and impact toughness, etc. through tensile testing, impact testing and other methods. These tests determine whether the strength and toughness of the welding wire meet standard requirements.

Welding performance evaluation: Welding performance evaluation is carried out through welding samples, including weld quality, crack sensitivity and hot crack resistance. This can be done by conducting welding tests and evaluating them.

Corrosion performance test: Corrosion performance test is performed on welded joints to evaluate the corrosion resistance of the welding wire. Common test methods include salt spray test, corrosion-resistant medium immersion test, etc.

Non-destructive testing: Use non-destructive testing methods, such as ultrasonic testing, radiographic testing, etc., to detect defects in the welding wire to ensure that the welding wire has no internal defects and cracks.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China