0

0

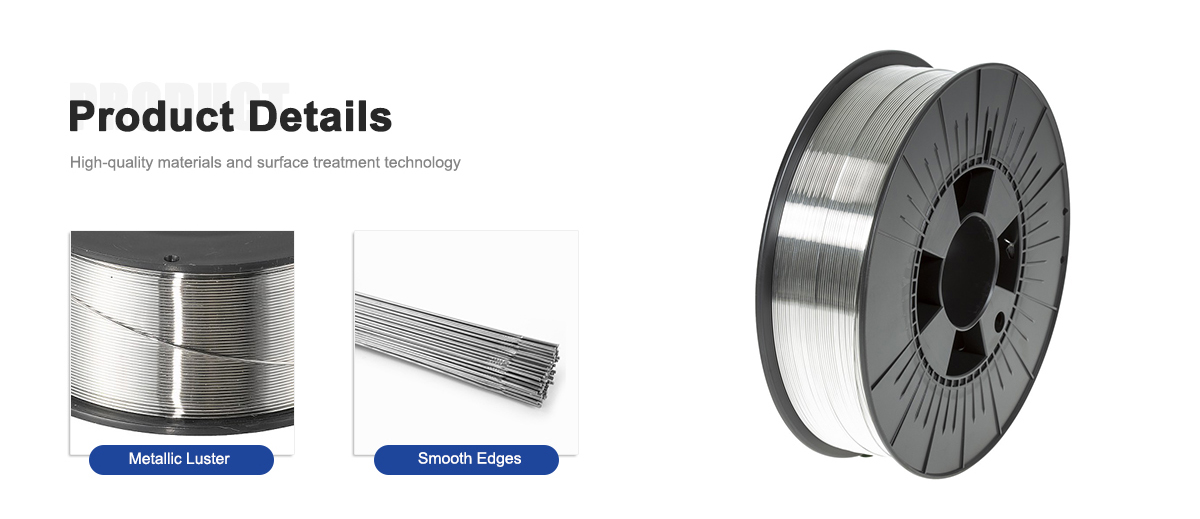

Products Description

Nickel-based welding wire plays an important role in steel manufacturing. As a commonly used welding material, nickel-based welding wire is widely used in the steel manufacturing process to weld, repair and connect key components.

Nickel-based welding wire offers several advantages in steel manufacturing. First, it has excellent high temperature resistance. During steel smelting and processing, high temperature environments are the norm. Nickel-based welding wire can maintain high strength and stability at high temperatures and is not prone to deformation and cracks, thereby ensuring the reliability and durability of welded joints.

Secondly, nickel-based welding wire has good corrosion resistance. In steel manufacturing, there are various corrosive media, such as acidic solutions, salt water and chemical gases, which can easily cause corrosion and erosion to welded joints and material surfaces. Nickel-based welding wire has high corrosion resistance and can effectively resist the erosion of these corrosive media and extend the service life of welded joints.

In addition, nickel-based welding wire also has good toughness and plasticity, making it easy to cope with complex processes and structural requirements in steel manufacturing. It can adapt to changes and stress concentrations in steel products, reduce stress concentrations caused by thermal expansion and contraction, and reduce the risk of thermal fatigue and fracture.

When selecting nickel-based welding wire for welding in steel manufacturing, factors such as the type of steel material, the requirements for the welded joint, and the expected conditions of use need to be considered. Reasonable selection of welding materials and corresponding welding processes can ensure welding quality, improve production efficiency, and meet the quality standards and requirements of steel manufacturing.

Welding series:

ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1, ER70S-6.

Standard: Conforms to Certification AWS A5.14 ASME SFA A5.14

Size: 0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM / 5.0MM

Form: MIG(15kgs/spool), TIG(5kgs/box),Strip

Product parameters:

Main component: nickel alloy (nickel is the main component, including other alloy elements)

Diameter range: usually between 0.8mm and 2.4mm

Strength: High strength and excellent mechanical properties

Corrosion resistance: able to resist corrosion from corrosive media and chemicals in the steel manufacturing process

Item | ERNiCrMo-3 | ERNiCrMo-4 | ERNiCrMo-13 | ERNiCrFe-7 | ERNiCr-3 | ERNiCu-7 | ERCuNi | ERNi-1 |

C | 0.1 | 0.02 | 0.01 | 0.04 | 0.1 | 0.15 | 0.03 | 0.15 |

Mn | 0.05 | 1 | 0.5 | 1 | 2.5-3.5 | 4 | 0.5-1.0 | 1 |

Fe | 5 | 4-7 | 1.5 | 7-11 | 3 | 2.5 | 0.65 | 1 |

P | 0.02 | 0.04 | 0.015 | 0.02 | 0.03 | 0.02 | 0.01 | 0.03 |

S | 0.015 | 0.03 | 0.005 | 0.015 | 0.015 | 0.015 | 0.01 | 0.015 |

Si | 0.05 | 0.08 | 0.1 | 0.5 | 0.5 | 1.25 | 0.15 | 0.75 |

Cu | 0.5 | 0.5 | N/A | 0.3 | 0.5 | rest | rest | 0.25 |

Ni | ≥58 | rest | rest | rest | ≥67 | 62-69 | 30-32 | ≥93 |

Co | N/A | 2.5 | 0.3 | N/A | N/A | N/A | N/A | N/A |

Al | 0.4 | N/A | 0.1-0.4 | 1.1 | N/A | 1.25 | 0.15 | 1.5 |

Ti | 0.4 | N/A | N/A | 1 | 0.75 | 1.5-3 | 0.5 | 2-3.5 |

Cr | 20-23 | 14.5-16.5 | 22-24 | 28.5-31 | 18.0-22.0 | N/A | N/A | N/A |

Nb+Ta | 3.5-4.15 | N/A | 1.8-2.5 | 0.01 | 2.0-3.0 | N/A | N/A | N/A |

Mo | 8.0-10 | 15-17 | 15-16 | 0.5 | N/A | N/A | N/A | N/A |

V | N/A | 0.35 | N/A | N/A | N/A | N/A | N/A | N/A |

W | N/A | 3.0-4.5 | N/A | N/A | N/A | N/A | N/A | N/A |

Rest | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 |

Nickel and Nickel Alloy Welding Wire | |

Product Model (AWS) | Application |

ERNiCr-3 | For welding 600, 601 and 800 alloys themselves, and welding dissimilar steels between stainless steel and carbon steel ERNiCrFe-7; For welding Inconel alloys within ASTM B163, 166, 167 and 168 |

ERNiCrFe-6 | For welding of steel and Inconel, welding of steel and stainless steel and nickel-based alloys |

ERNiCrCoMo-1 | Dissimilar welding for welding nickel-chromium-cobalt-molybdenum alloys and various superalloys |

ERNiCrMo-3 | It is used for welding of nickel alloy, carbon steel, stainless steel and low alloy steel, mainly used for welding of 625, 601, 802 alloy and welding of 9% nickel alloy |

ERNi-CI | Industrial pure nickel for welding malleable and grey cast iron |

ERCuNi | For welding of 70/30, 80/20, 90/10 copper-nickel alloys |

ERNiCu-7 | For welding nickel copper alloys B127, 163, 164 and 165 etc. |

ERNi-1 | For welding of pure nickel castings and forgings such as alloys within ASTM B160, 161, 162, 163 |

ERNiFeMn-CI | For welding of nodular cast iron, ductile iron, malleable cast iron and grey cast iron to itself or to stainless steel, carbon steel, low alloy steel and various nickel alloys |

ERNiCrMo-4 | For welding nickel-chromium-molybdenum alloy itself, or welding nickel-chromium-molybdenum alloy and steel and most other nickel-based alloys |

ERNiCrMo-11 | It is used for welding of nickel-chromium-molybdenum alloy itself, or welding of nickel-chromium-molybdenum alloy and steel and most other nickel-based alloys, and can also be used for surfacing welding of nickel-chromium-molybdenum alloy and steel welding seam |

ERNiCrMo-13 | For welding low carbon nickel chromium molybdenum alloys |

Product Features:

Corrosion resistance: Nickel-based welding wire has excellent corrosion resistance and can resist the erosion of chemicals and corrosive media in the steel manufacturing process, ensuring the long-term durability of welded joints.

High strength: Nickel-based welding wire has high strength and excellent mechanical properties, and can withstand pressure and load during the steel manufacturing process, improving the structural strength and reliability of welded joints.

Weldability: Nickel-based welding wire has good welding performance and can perform good welding with common metal materials such as steel, ensuring the quality and reliability of welded joints.

Good thermal stability: Nickel-based welding wire has good thermal stability in high temperature environments and can maintain the stability and performance of welded joints.

Specific applications:

Nickel-based welding wire has a wide range of applications in the field of steel manufacturing, including but not limited to the following:

Fabrication and welding of steel structures such as bridges, building structures, etc.

Manufacturing and welding of steel pipes, such as oil pipelines, natural gas pipelines, etc.

Fabrication and repair of steel vessels and tanks, such as chemical vessels, storage tanks, etc.

Other relevant knowledge points:

The quality of nickel-based welding wire is crucial to the quality and reliability of steel manufacturing and requires strict compliance with relevant quality standards and welding specifications.

Welding processes and parameters in steel manufacturing have an important impact on the quality and performance of welded joints and need to be reasonably selected and controlled according to specific requirements.

The application of nickel-based welding wire in the steel manufacturing process needs to match other processes and materials to ensure the coordination and consistency of the overall process.

FAQ

What are the applications of nickel-based welding wire in the aviation field?

Nickel-based welding wire is commonly used in the aviation field to repair aero engines, aircraft structural parts, etc.

What is the strength of the welded joint of nickel-based welding wire?

The welded joint of nickel-based welding wire has high strength and good sealing.

How is the processability of nickel-based welding wire?

Nickel-based welding wire has good processability and can adapt to welding needs of complex shapes and sizes.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China