0

0

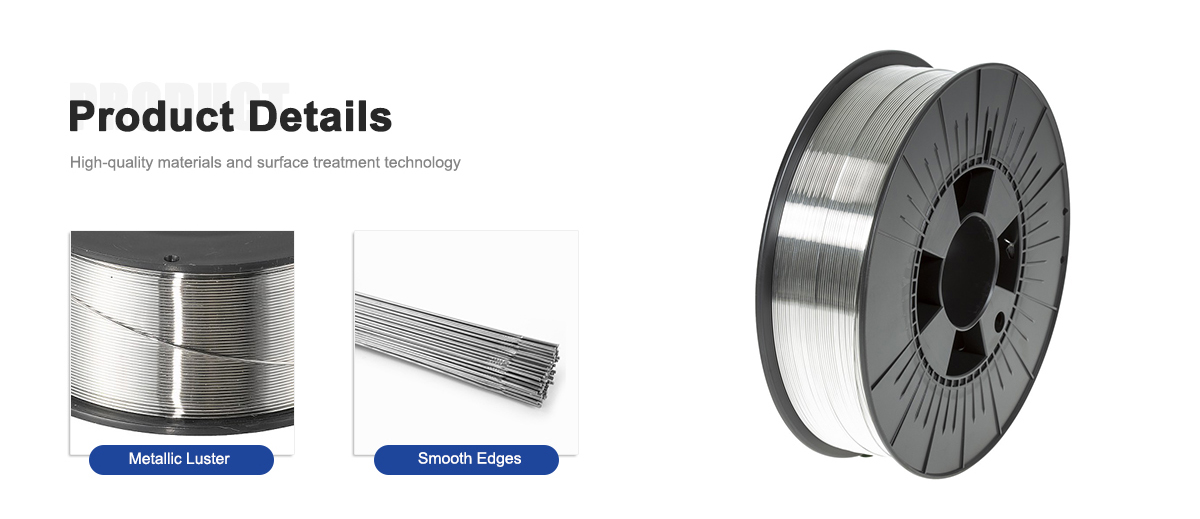

Products Description

Nickel-based welding wire has a wide range of applications in the medical device field. As an important material in the medical device manufacturing process, nickel-based welding wire plays an important role in welding and connecting key components.

The use of nickel-based welding wire in medical devices has several advantages. First, it has excellent corrosion resistance. Medical devices are often exposed to corrosive body fluids, drugs or chemical disinfectants, and nickel-based welding wire can resist the erosion of these corrosive media, extending the service life of the device and improving its durability.

Secondly, nickel-based welding wire has good strength and reliability. Medical devices often need to withstand a certain amount of force and pressure, so welded joints must have sufficient strength and reliability to ensure the stability and safety of the device. Nickel-based welding wire provides a high-strength welding joint that resists external forces, ensuring that the device will not break or loosen during use.

In addition, nickel-based welding wire also has good processability and plasticity, making it easy to manufacture medical devices with complex shapes and fine structures. It can meet the requirements of medical device design and provide customized solutions.

In the manufacturing process of medical devices, it is crucial to select suitable nickel-based wire materials and welding processes. Factors such as the environment in which the device is used, the compatibility of the device materials, and the requirements for the welded joints need to be considered to ensure the quality of the welding and the performance and reliability of the device. In addition, quality control and welding monitoring are also critical steps to ensure the quality of welded joints and compliance with relevant standards and regulatory requirements for medical devices.

Welding series:

ERNiCrMo-3,ERNiCrMo-4,ERNiCrMo-13,ERNiCrFe-3,ERNiCrFe-7,ERNiCr-3,ERNiCr-7,ERNiCu-7,ERNi-1, ER70S-6.

Standard: Conforms to Certification AWS A5.14 ASME SFA A5.14

Size: 0.8MM / 1.0MM / 1.2MM / 1.6MM / 2.4MM / 3.2MM / 3.8MM / 4.0MM / 5.0MM

Form: MIG(15kgs/spool), TIG(5kgs/box),Strip

Parameter:

Main component: nickel alloy (nickel is the main component, including other alloy elements)

Diameter range: usually between 0.8mm and 2.4mm

Strength: High strength and excellent mechanical properties

Corrosion resistance: able to resist corrosion from corrosive media and chemicals in medical devices

Item | ERNiCrMo-3 | ERNiCrMo-4 | ERNiCrMo-13 | ERNiCrFe-7 | ERNiCr-3 | ERNiCu-7 | ERCuNi | ERNi-1 |

C | 0.1 | 0.02 | 0.01 | 0.04 | 0.1 | 0.15 | 0.03 | 0.15 |

Mn | 0.05 | 1 | 0.5 | 1 | 2.5-3.5 | 4 | 0.5-1.0 | 1 |

Fe | 5 | 4-7 | 1.5 | 7-11 | 3 | 2.5 | 0.65 | 1 |

P | 0.02 | 0.04 | 0.015 | 0.02 | 0.03 | 0.02 | 0.01 | 0.03 |

S | 0.015 | 0.03 | 0.005 | 0.015 | 0.015 | 0.015 | 0.01 | 0.015 |

Si | 0.05 | 0.08 | 0.1 | 0.5 | 0.5 | 1.25 | 0.15 | 0.75 |

Cu | 0.5 | 0.5 | N/A | 0.3 | 0.5 | rest | rest | 0.25 |

Ni | ≥58 | rest | rest | rest | ≥67 | 62-69 | 30-32 | ≥93 |

Co | N/A | 2.5 | 0.3 | N/A | N/A | N/A | N/A | N/A |

Al | 0.4 | N/A | 0.1-0.4 | 1.1 | N/A | 1.25 | 0.15 | 1.5 |

Ti | 0.4 | N/A | N/A | 1 | 0.75 | 1.5-3 | 0.5 | 2-3.5 |

Cr | 20-23 | 14.5-16.5 | 22-24 | 28.5-31 | 18.0-22.0 | N/A | N/A | N/A |

Nb+Ta | 3.5-4.15 | N/A | 1.8-2.5 | 0.01 | 2.0-3.0 | N/A | N/A | N/A |

Mo | 8.0-10 | 15-17 | 15-16 | 0.5 | N/A | N/A | N/A | N/A |

V | N/A | 0.35 | N/A | N/A | N/A | N/A | N/A | N/A |

W | N/A | 3.0-4.5 | N/A | N/A | N/A | N/A | N/A | N/A |

Rest | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 | ≤0.50 |

Nickel and Nickel Alloy Welding Wire | |

Product Model (AWS) | Application |

ERNiCr-3 | For welding 600, 601 and 800 alloys themselves, and welding dissimilar steels between stainless steel and carbon steel ERNiCrFe-7; For welding Inconel alloys within ASTM B163, 166, 167 and 168 |

ERNiCrFe-6 | For welding of steel and Inconel, welding of steel and stainless steel and nickel-based alloys |

ERNiCrCoMo-1 | Dissimilar welding for welding nickel-chromium-cobalt-molybdenum alloys and various superalloys |

ERNiCrMo-3 | It is used for welding of nickel alloy, carbon steel, stainless steel and low alloy steel, mainly used for welding of 625, 601, 802 alloy and welding of 9% nickel alloy |

ERNi-CI | Industrial pure nickel for welding malleable and grey cast iron |

ERCuNi | For welding of 70/30, 80/20, 90/10 copper-nickel alloys |

ERNiCu-7 | For welding nickel copper alloys B127, 163, 164 and 165 etc. |

ERNi-1 | For welding of pure nickel castings and forgings such as alloys within ASTM B160, 161, 162, 163 |

ERNiFeMn-CI | For welding of nodular cast iron, ductile iron, malleable cast iron and grey cast iron to itself or to stainless steel, carbon steel, low alloy steel and various nickel alloys |

ERNiCrMo-4 | For welding nickel-chromium-molybdenum alloy itself, or welding nickel-chromium-molybdenum alloy and steel and most other nickel-based alloys |

ERNiCrMo-11 | It is used for welding of nickel-chromium-molybdenum alloy itself, or welding of nickel-chromium-molybdenum alloy and steel and most other nickel-based alloys, and can also be used for surfacing welding of nickel-chromium-molybdenum alloy and steel welding seam |

ERNiCrMo-13 | For welding low carbon nickel chromium molybdenum alloys |

Product Features:

Corrosion resistance: Nickel-based welding wire has excellent corrosion resistance and can withstand the corrosion of chemicals and body fluids in medical devices, ensuring the long-term durability of welded joints.

High strength: Nickel-based welding wire has high strength and excellent mechanical properties. It can withstand pressure and load during the use of medical devices, improving the structural strength and reliability of welded joints.

Weldability: Nickel-based welding wire has good welding performance and can be welded well with common medical device materials such as stainless steel, titanium alloys, etc., ensuring the quality and reliability of welded joints.

Biocompatibility: Nickel-based welding wire has excellent biocompatibility, meets the biosafety requirements of medical device materials, and will not have a negative impact on human tissues and organisms.

Specific applications:

Nickel-based welding wire has a wide range of applications in the field of medical devices, including but not limited to the following:

Manufacturing and repair of surgical instruments, such as surgical forceps, scissors, etc.

Connection and assembly of medical equipment, such as medical stainless steel equipment, implantable medical equipment, etc.

Manufacturing and repair of artificial joints, such as artificial hip joints, artificial knee joints, etc.

Other relevant knowledge points:

Medical device manufacturing has very strict requirements on welding materials, and nickel-based welding wire can meet these requirements and provide reliable welding solutions.

Welding medical devices requires strict compliance with relevant quality standards and safety regulations to ensure the quality and reliability of welded joints.

The quality inspection of nickel-based welding wire is particularly important in medical device welding, including composition analysis, metallographic structure analysis, mechanical property testing, biocompatibility testing, etc.

Advantage:

Nickel-based welding wire has the following advantages compared to other materials:

Corrosion resistance: Nickel-based welding wire has excellent corrosion resistance and can withstand corrosion in acidic, alkaline and high-temperature environments. In contrast, some common structural materials such as carbon steel and stainless steel are susceptible to erosion and damage in corrosive environments.

High temperature performance: Nickel-based welding wire can maintain good performance in high temperature environments and has a high melting point and thermal stability. This makes nickel-based welding wire advantageous in high-temperature processes and applications such as aerospace, energy industries and petrochemicals.

High strength: Nickel-based welding wire has high strength and excellent mechanical properties, and can withstand large loads and pressures. Compared with some traditional welding materials, nickel-based welding wire performs better in terms of structural strength and reliability.

Good weldability: Nickel-based welding wire has good weldability and can perform good welding with a variety of common metal materials such as stainless steel, titanium alloys, etc. This makes nickel-based welding wire widely used in fields such as medical devices, aerospace, energy and automobile manufacturing.

Biocompatibility: Nickel-based welding wire has excellent biocompatibility and meets the biosafety requirements of medical device materials. In medical device manufacturing, nickel-based welding wire can be used to manufacture implantable medical devices and artificial joints without having a negative impact on human tissues and organisms.

It should be noted that different materials may have different advantages in different application areas and specific requirements. Selecting the appropriate material should take into account specific application needs, environmental conditions and performance requirements. In actual applications, it is recommended to make material selection based on specific conditions and refer to relevant material performance tables and technical guidelines.

FAQ:

How to evaluate the welding quality of nickel-based welding wire?

Welding quality can be evaluated by the strength, appearance quality, metal structure, etc. of the weld.

Are there any common application considerations for nickel-based welding wire?

When using nickel-based welding wire, attention needs to be paid to preventing oxidation, maintaining appropriate welding temperature, and avoiding stress concentration to ensure welding quality and performance.

What are the storage and maintenance requirements for nickel-based welding wire?

Nickel-based welding wire should be stored in a dry, ventilated, non-corrosive gas environment to avoid moisture and contamination by other impurities.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China