0

0

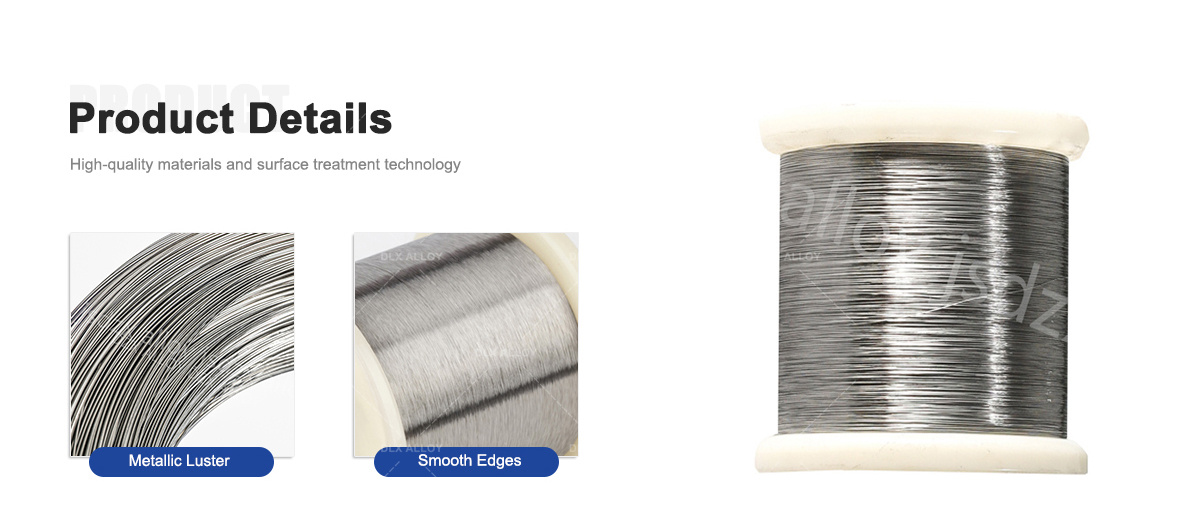

Products Description

Inconel alloy wire is a special alloy material with excellent high temperature properties. It is composed of elements such as nickel, chromium and iron, as well as other added elements such as molybdenum, titanium and aluminum. This alloy wire exhibits excellent corrosion resistance, oxidation resistance and high strength properties in high temperature environments.

Due to its excellent high temperature properties, Inconel alloy wire is widely used in aerospace, chemical, energy and petroleum industries. It is used to manufacture high-temperature components such as combustion chambers, gas turbines, boiler piping and chemical plants to meet the requirements of extreme working conditions. At the same time, Inconel alloy wire is also widely used in the heat treatment industry and high-temperature experimental equipment to provide reliable material solutions.

Physical property

Density: ρ=8.28g/cm3

Melting temperature range: 1393-1427℃

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

High temperature performance

Inconel alloy wire has attracted much attention for its excellent high temperature performance. As a high-temperature alloy material, it performs well in extreme temperature environments and has the following characteristics:

High temperature strength: Inconel alloy wire maintains excellent strength and stability under high temperature conditions. It can withstand mechanical loads such as tension, compression and bending at high temperatures, and is not prone to deformation or breakage, ensuring the reliability and durability of the equipment.

Oxidation resistance: Inconel alloy wire has excellent oxidation resistance. In a high-temperature environment, it can form a dense oxide layer, called a "passivation layer", which effectively prevents direct contact between oxygen and the alloy and reduces the occurrence of oxidation reactions. This gives Inconel alloy wire excellent durability in high temperature oxidizing environments.

Hot corrosion resistance: Inconel alloy wire exhibits excellent hot corrosion resistance. It can resist the erosion of acids, alkalis, salts and other corrosive media at high temperatures. This makes Inconel alloy wire an ideal material choice for widespread use in high-temperature corrosive environments in the chemical, petroleum, electric power and other industries.

Thermal stability: Inconel alloy wire has good thermal stability and can maintain stable performance under long-term high temperature exposure. It is not prone to problems such as grain boundary creep, thermal fatigue and fracture, and is suitable for applications that require long-term operation under high temperature conditions.

Thermal expansion matching: The thermal expansion coefficient of Inconel alloy wire matches that of many metallic and ceramic materials, making it suitable for high temperature packaging, soldering and joining applications. It reduces the risk of thermal stress and thermal cracking caused by thermal expansion mismatch.

Methods

In high temperature environments, the oxidation resistance of Inconel alloy wire is mainly maintained through the following methods:

Passivation layer formation: Inconel alloy wire reacts with oxygen at high temperatures to form a dense oxide layer, called a "passivation layer". This oxide layer can block further penetration of oxygen and slow down the oxidation rate of the alloy. The passivation layer is usually composed of nickel oxide and chromium oxide and has good oxidation resistance.

High Chromium Content: The chromium content in Inconel alloy wire is relatively high, usually between 15% and 25%. Chromium is an element that reacts with oxygen to form stable oxides. High chromium content helps form a denser and more stable oxide layer, improving the alloy's oxidation resistance.

Alloy element ratio: Other alloy elements in Inconel alloy wire, such as nickel, aluminum, titanium, etc., will also affect the oxidation resistance. The reasonable ratio of these elements can enhance the stability and oxidation resistance of the alloy. For example, aluminum and titanium are oxygen-philic and can react with oxygen to form oxides, further improving the alloy's oxidation resistance.

Structural stability at high temperatures: Inconel alloy wire can maintain good structural stability at high temperatures and is not prone to problems such as grain boundary creep, grain growth and phase transformation. This helps maintain the uniformity and density of the alloy and reduces pathways for oxygen penetration.

Control oxygen content: When manufacturing and using Inconel alloy wire, the oxygen content in the environment needs to be strictly controlled. By using an inert gas environment (such as nitrogen) during high-temperature processing, the contact of oxygen with the alloy can be reduced and the occurrence of oxidation reactions can be reduced.

Best operating temperature

The optimal operating temperature of Inconel alloy wire depends on the specific grade and alloy composition. Different Inconel alloys have different high temperature properties and usage limitations. The following are some common Inconel alloys and their recommended maximum service temperature ranges:

Inconel 600: Recommended operating temperature range is approximately -109°C to 1093°C (-165°F to 2000°F).

Inconel 625: Recommended operating temperature range is approximately -196°C to 1093°C (-320°F to 2000°F). Excellent corrosion resistance at high temperatures.

Inconel 718: Recommended operating temperature range is approximately -253°C to 704°C (-423°F to 1300°F). It has good strength and creep resistance in high temperature and high stress environments.

Inconel X-750: Recommended operating temperature range is approximately -253°C to 704°C (-423°F to 1300°F). It has good strength and creep resistance under high temperature stress environment.

It should be noted that these recommended maximum service temperatures are for reference only, and actual service temperatures will need to be evaluated based on specific application conditions, stress levels, and alloy integrity. In addition, for long-term use and special applications, the effects of factors such as oxidation, creep, fatigue and corrosion of the alloy need to be considered.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China