0

0

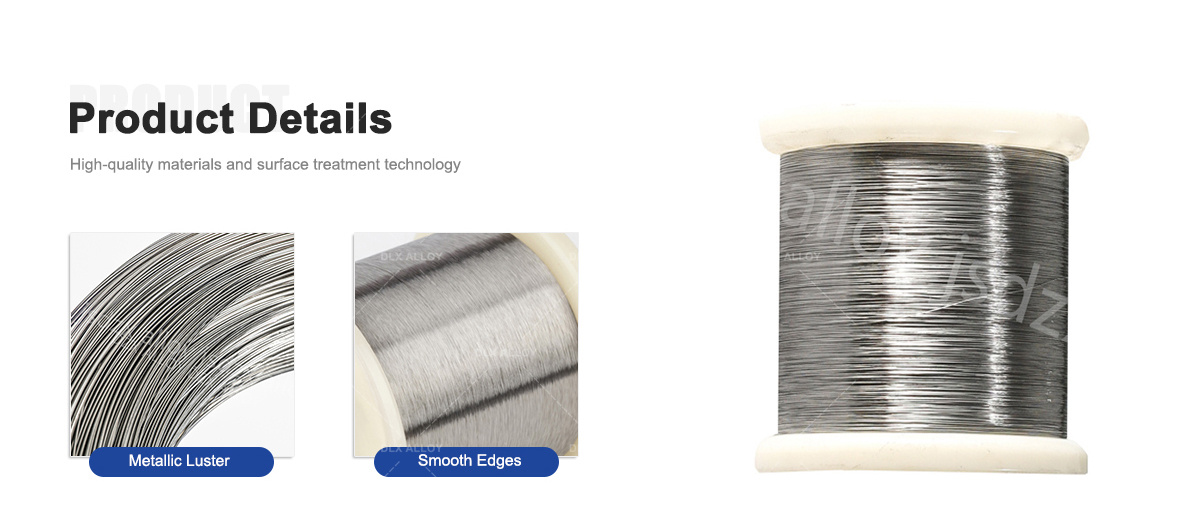

Products Description

Inconel alloy wire is a high-performance alloy material composed of elements such as nickel and chromium. It has excellent corrosion resistance, high temperature stability and mechanical properties.

Inconel alloy wire exhibits excellent corrosion resistance in harsh environments. It can resist the erosion of various corrosive media such as acid, alkaline, oxidizing and salt water, including sulfuric acid, hydrochloric acid, chloride and sea water. This makes it the material of choice for corrosion-resistant components and equipment in fields such as chemical, petrochemical and offshore engineering.

At the same time, Inconel alloy wire performs well in high temperature environments. It maintains good strength and hardness under extreme high temperatures and forms a dense oxide layer to resist further oxidation and corrosion. This makes it widely used in high temperature applications such as aerospace, aircraft engines and heat treatment equipment.

In addition, Inconel alloy wire has excellent mechanical properties. It has high strength, good fatigue resistance and stress corrosion cracking resistance, and can withstand complex mechanical loads and extreme working conditions. Therefore, it is widely used in high-strength structures and components in aerospace, automotive, chemical and energy fields.

Overall, Inconel alloy wire plays an important role in various industrial fields due to its excellent properties such as corrosion resistance, high temperature resistance and mechanical properties. It provides reliable and durable solutions for engineering design and meets the needs of various extreme working conditions.

Physical property

Density: ρ=8.28g/cm3

Melting temperature range: 1393-1427℃

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Application areas

Aerospace industry:

Application: Inconel alloy wire is widely used in the aerospace industry to manufacture parts in high-temperature and corrosive environments, such as jet engine components, turbine blades, combustion chamber parts, burner nozzles, etc.

Features: It has excellent high temperature strength and corrosion resistance, and can maintain stability and reliability under high temperature, high pressure and harsh environments.

Chemical industry:

Application: Inconel alloy wire is used to manufacture corrosion-resistant chemical equipment, such as pipes, valves, pumps and heat exchangers, etc. It is widely used in harsh environments such as acidic, alkaline, high temperature and high pressure.

Characteristics: Excellent corrosion resistance, showing low corrosion rate and long service life in corrosive media.

Oil and Gas Industry:

Application: Inconel alloy wire is used in oil well casing, oil well sucker rods, oil and gas pipelines and valves in the oil and gas industry. It has good durability under high temperature, high pressure and corrosive environment.

Characteristics: It is resistant to high temperature, corrosion and hydrogen sulfide corrosion, and can cope with the harsh conditions in oil field mining and oil and gas transportation.

Nuclear energy industry:

Application: Inconel alloy wire is used in key components such as nuclear reactor fuel elements, control rods, coolant pipelines and steam generators in nuclear power plants in the nuclear energy industry.

Characteristics: It has excellent high-temperature strength, radiation resistance and corrosion resistance, and can withstand extreme conditions such as high temperature, radiation and chemical corrosion in the nuclear energy industry.

medical instruments:

Application: Inconel alloy wire is used to manufacture components in high temperature and corrosive environments in medical devices, such as artificial joints, implantable devices and surgical instruments.

Features: Biocompatibility, high temperature strength and corrosion resistance provide reliable and durable solutions in the medical field.

auto industry:

Application: Inconel alloy wire is used in components such as turbochargers, exhaust systems, exhaust valves and high temperature sensors in the automotive industry.

Characteristics: It has high temperature strength, corrosion resistance and mechanical properties, and can withstand the high temperature and corrosion requirements in automobile engines and exhaust systems.

FAQ

Q: What is the difference between Inconel alloy wire and stainless steel wire?

Answer: Compared with stainless steel wire, Inconel alloy wire has better high temperature strength and corrosion resistance. It can maintain stability at higher temperatures and has higher corrosion resistance against acidic, alkaline and other corrosive media.

Q: Does the thermal expansion coefficient of Inconel alloy wire match that of other metals?

A: Yes, the thermal expansion coefficient of Inconel alloy wire matches that of many metallic and ceramic materials. This allows it to reduce problems caused by thermal expansion mismatch when forming connections with other materials and provide a more reliable connection.

Q: In which industries are Inconel alloy wires widely used?

Answer: Inconel alloy wire is widely used in the aerospace industry, chemical industry, oil and gas industry, nuclear energy industry, medical equipment and automobile industry. Its applications in these industries mainly involve the manufacturing of parts under high temperature, high pressure and corrosive environments.

Q: What are the steps involved in the manufacturing process of Inconel alloy wire?

Answer: The manufacturing process of Inconel alloy wire usually includes steps such as smelting, continuous casting, hot rolling, and cold drawing. First, the raw materials are melted and alloyed through smelting, and then continuous billets are obtained through continuous casting, followed by processing steps such as hot rolling and cold drawing to obtain alloy wires of the required diameter and shape.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China