0

0

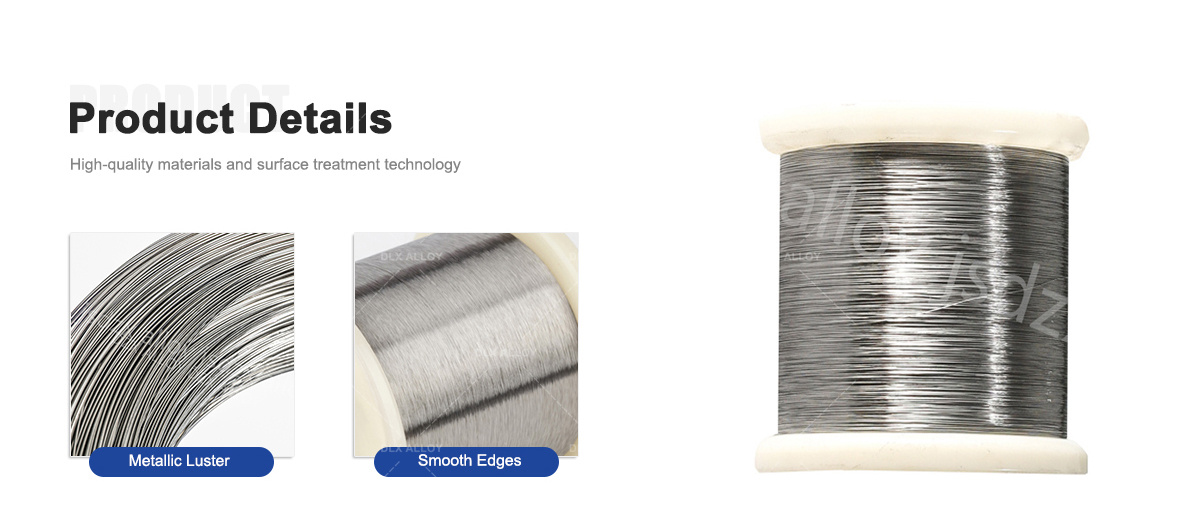

Products Description

Inconel alloy wire is known for its excellent high strength and excellent mechanical properties, making it an ideal material for a wide range of applications at high temperatures and extreme working conditions.

First, Inconel alloy wire has excellent tensile strength and yield strength. This kind of alloy wire can maintain a high strength level in high temperature environments and withstand large tensile loads. Its high strength properties allow alloy wire to maintain structural integrity and stability under extreme working conditions.

Secondly, Inconel alloy wire exhibits excellent fatigue resistance and resistance to stress corrosion cracking. It can maintain stable performance for a long time under repeated loading and is not prone to fatigue fracture. At the same time, the alloy wire's ability to resist stress corrosion cracking enables it to maintain the integrity of the material in environments subject to the combined effects of stress and corrosive media.

In addition, Inconel alloy wire also has good hardness and wear resistance. It has a high hardness level and can maintain good mechanical rigidity in high temperature environments. At the same time, the wear-resistant performance of the alloy wire enables it to resist surface wear and erosion by abrasive particles, extending the service life of the material.

Finally, the low thermal expansion coefficient and excellent thermal fatigue performance of Inconel alloy wire are also worth mentioning. Its low thermal expansion coefficient allows the alloy wire to maintain good dimensional stability under high temperature conditions and reduce problems caused by thermal stress. At the same time, the excellent thermal fatigue properties of the alloy wire enable it to resist thermal fatigue fracture under high-temperature cycle conditions and maintain the reliability and life of the material.

Physical property

Density: ρ=8.28g/cm3

Melting temperature range: 1393-1427℃

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Excellent mechanical properties

Inconel alloy wire is known for its high strength and excellent mechanical properties. The following is an introduction to the high strength and mechanical properties of Inconel alloy wire:

High Strength: Inconel alloy wire has excellent high strength properties. This is due to the high proportion of elements such as nickel, chromium and iron in its composition, as well as the addition of other alloying elements. The combination of these elements gives Inconel alloy wire good tensile strength, yield strength and fatigue resistance. The high strength allows Inconel alloy wire to withstand large forces and stresses under high loads and extreme environments, giving it superior reliability in a variety of industrial applications.

Heat resistance: Inconel alloy wire has excellent heat resistance. It can maintain the stability of its mechanical properties in high temperature environments. Even under extreme high-temperature conditions, such as in aerospace engine combustion chambers or high-temperature furnaces, Inconel alloy wire maintains its strength and rigidity and is not easily softened or deformed.

Good creep and fatigue properties: Inconel alloy wire has good creep and fatigue properties. Creep is the slow deformation of materials under high temperatures and sustained stress, while fatigue is the failure of materials under alternating loading. Through reasonable alloy design and heat treatment, Inconel alloy wire can effectively resist failure caused by creep and fatigue, thereby extending its service life.

Corrosion resistance: In addition to high strength and heat resistance, Inconel alloy wire also has good corrosion resistance. It can withstand a variety of corrosive media, including acidic, alkaline and chloride environments. This makes Inconel alloy wires have broad application prospects in highly corrosive applications such as the chemical industry and marine environments.

Overall, Inconel alloy wire performs well in various high temperature and high stress environments with its high strength and excellent mechanical properties. This makes it an important material in aerospace, petrochemical, energy and other fields, and is widely used in aerospace engines, chemical reactors, high-temperature pipelines and other applications that require high strength and heat resistance.

Characteristic

When it comes to the high strength and mechanical properties of Inconel alloy wire, there are some further aspects worth knowing:

High temperature strength: Inconel alloy wire maintains high strength in high temperature environments. This makes it ideal as a replacement for traditional materials in high-temperature applications. At high temperatures, where many conventional materials soften and lose strength, Inconel alloy wire maintains high mechanical properties, including tensile strength, yield strength and hardness.

Anti-fatigue properties: Inconel alloy wire has excellent anti-fatigue properties, that is, it maintains its strength and durability under alternating or cyclic loading. This is important for applications requiring long-term cyclic loading, such as turbine blades and engine parts in the aerospace sector.

Resistance to stress corrosion cracking: Stress corrosion cracking is a rupture phenomenon that occurs when materials are subjected to stress and corrosive media at the same time. Inconel alloy wire has excellent resistance to stress corrosion cracking due to its corrosion resistance and high strength. This makes it particularly valuable in chemical, petroleum and marine applications.

Weldability: Inconel alloy wire has good weldability, which means it can make reliable welding connections with other materials. This is important for manufacturing complex structures and components, as well as for repair and maintenance work.

Rigidity and stability: Inconel alloy wire has good rigidity and dimensional stability. This means that it is not prone to significant deformation or deformation under temperature changes or stress loading, maintaining its designed shape and performance.

Abrasion and corrosive wear resistance: Inconel alloy wire has excellent resistance to abrasion and corrosive wear. This gives it long-term durability in high friction and corrosive environments and makes it suitable for applications requiring high wear resistance, such as turbomachinery and pumping systems.

In summary, Inconel alloy wire is favored for its high-temperature strength, fatigue resistance, stress corrosion cracking resistance, weldability, rigidity and stability, as well as wear and corrosion wear resistance. These characteristics enable it to perform well in various high temperature, high stress and harsh environments, and are widely used in aerospace, energy, chemical, petroleum and marine fields.

Compared

Inconel alloy wire is usually a high-priced material compared to other materials. The price will be affected by many factors, including alloy composition, specification requirements, market supply and demand, and purchase quantity.

Inconel alloy is a high-performance alloy whose composition contains precious metals such as nickel, chromium, and iron, as well as other alloying elements such as molybdenum, titanium, and aluminum. The higher cost of these precious metals and alloy elements also leads to the higher price of Inconel alloy.

In addition, the manufacturing process of Inconel alloy is relatively complex, including smelting, heat treatment, processing and testing, which will increase production costs and further push up prices.

In comparison, the prices of some common ordinary materials such as stainless steel and carbon steel are relatively low because their ingredients are relatively simple, the production process is relatively simple, and the supply chain is relatively mature.

Overall, Inconel alloy wire is more expensive, but its unique properties such as high temperature, corrosion resistance and high strength make it still widely used in some special fields and applications. When selecting materials, performance requirements, cost factors, and special requirements of the application scenario need to be comprehensively considered.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China