0

0

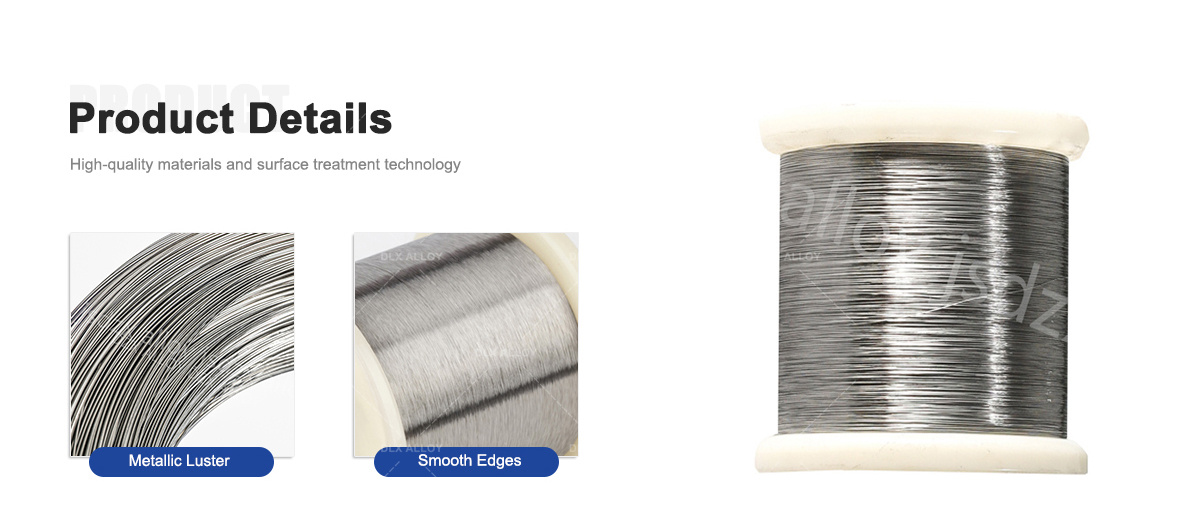

Products Description

Inconel alloy wire is a highly regarded material of choice in modern high temperature and corrosive environments. As a high-temperature alloy wire, Inconel alloy wire is world-famous for its excellent performance and reliable corrosion resistance.

Inconel alloy wire uses a careful blend of nickel, chromium and other alloy elements to provide excellent high-temperature strength and durability. It maintains stability and strength in extreme high-temperature environments and can withstand temperatures up to over 1,000 degrees Celsius. This makes Inconel alloy wire an indispensable material in aerospace, energy and petrochemical industries.

Inconel alloy wires are available in a variety of grades and parameters to meet the needs of various applications. Common Inconel alloy grades include Inconel 600, Inconel 625, Inconel 718, etc. These grades have slight differences in alloy composition and properties and are suitable for different engineering and application scenarios.

Parameter

Diameter: The diameter of Inconel alloy wire is usually marked in millimeters (mm) or inches (inch). Common diameters range from 0.05 mm to 5.0 mm, depending on application requirements.

Tensile Strength: The tensile strength of Inconel alloy wire refers to the maximum tensile force that the material can withstand during the stretching process. Tensile strength is usually expressed in units of megapascals (MPa) or pounds-force per square inch (psi). Common Inconel alloy wire tensile strengths range from 500 MPa to 1500 MPa.

Yield Strength: The yield strength of Inconel alloy wire refers to the maximum stress at which the material begins to undergo plastic deformation during the stretching process. Yield strength is usually expressed in units of megapascals (MPa) or pounds of force per square inch (psi). Common Inconel alloy wire yield strengths range from 200 MPa to 1200 MPa.

Elongation: The elongation of Inconel alloy wire refers to the degree of plastic deformation of the material during the stretching process, usually expressed as a percentage. Common Inconel alloy wire elongation ranges from 10% to 40%.

Density: The density of Inconel alloy wire refers to the mass per unit volume, usually expressed in grams/cubic centimeter (g/cm³) or pounds/cubic inch (lb/in³). The density of Inconel alloy wire is approximately 8.2 g/cm³.

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

Corrosion resistance

Inconel alloy wire has excellent corrosion resistance and can resist the erosion of various corrosive media. It performs well against various corrosive substances such as acids, alkalis, salts and oxidizing media. Whether in normal temperature environment or high temperature and high pressure environment, Inconel alloy wire can maintain the stability and performance of its material.

For seawater environments, Inconel alloy wire has excellent resistance to seawater corrosion and is not easily corroded by ocean salt spray and chlorine ions in seawater. Therefore, it is widely used in marine engineering, offshore platforms and seawater treatment equipment.

In acidic environments, Inconel alloy wire can resist corrosion from strong acids such as sulfuric acid, hydrochloric acid, and nitric acid. It is widely used in the chemical industry, petrochemical industry and acid storage tanks.

In addition, Inconel alloy wire also has excellent oxidation resistance and can resist oxidation in high-temperature oxidizing environments. It performs well in applications such as high-temperature stoves, burners and heat treatment equipment.

Overall, the corrosion resistance of Inconel alloy wire makes it an ideal choice for areas with high corrosion resistance requirements. Whether in chemical industry, petrochemical industry, marine engineering or high temperature applications, Inconel alloy wire can provide reliable corrosion resistance and ensure long-term stable operation of equipment.

Reasons for corrosion resistance

Alloy composition: The composition of Inconel alloy wire contains a high proportion of nickel and chromium, as well as other alloying elements such as molybdenum, iron, titanium, etc. The addition of these alloying elements can enhance the corrosion resistance of the alloy. Nickel provides good corrosion resistance, while chromium forms a dense oxide layer, called a "passivation layer", that prevents further corrosion reactions.

Crystal structure: Inconel alloy wire has a face-centered cubic structure (FCC), which gives the alloy good resistance to stress corrosion cracking. It remains stable under stress, reducing the occurrence of corrosion.

Oxide layer: The dense oxide layer formed on the surface of Inconel alloy wire can provide an additional protective layer, prevent the corrosive medium from direct contact with the alloy, and slow down the corrosion reaction.

Improve corrosion resistance

Optimizing alloy composition: By adjusting the proportion of elements in the alloy and adding other alloying elements, the corrosion resistance of the alloy can be further improved.

Surface treatment: Surface treatment methods such as polishing, pickling, shot peening, etc. can be used to remove impurities and oxide layers on the surface and improve the corrosion resistance of the alloy wire.

Anti-corrosion coating: Coating an anti-corrosion coating on the surface of alloy wire can provide an additional layer of protection and delay the occurrence of corrosion.

Control environmental conditions: In the environment where Inconel alloy wire is used, controlling environmental conditions such as temperature, humidity, and gas composition can reduce the erosion of the alloy by corrosive media.

It should be noted that although Inconel alloy wire has excellent corrosion resistance, corrosion may still occur in special corrosive environments. Therefore, it is still necessary to select appropriate materials and corrosion protection measures based on actual conditions in specific applications.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China