0

0

Products Description

Inconel alloy wire is a high-performance alloy material composed of elements such as nickel and chromium. It has excellent corrosion resistance, high temperature stability and mechanical properties.

Inconel alloy wire exhibits excellent corrosion resistance in harsh environments. It can resist the erosion of various corrosive media such as acid, alkaline, oxidizing and salt water, including sulfuric acid, hydrochloric acid, chloride and sea water. This makes it the material of choice for corrosion-resistant components and equipment in fields such as chemical, petrochemical and offshore engineering.

At the same time, Inconel alloy wire performs well in high temperature environments. It maintains good strength and hardness under extreme high temperatures and forms a dense oxide layer to resist further oxidation and corrosion. This makes it widely used in high temperature applications such as aerospace, aircraft engines and heat treatment equipment.

In addition, Inconel alloy wire has excellent mechanical properties. It has high strength, good fatigue resistance and stress corrosion cracking resistance, and can withstand complex mechanical loads and extreme working conditions. Therefore, it is widely used in high-strength structures and components in aerospace, automotive, chemical and energy fields.

Overall, Inconel alloy wire plays an important role in various industrial fields due to its excellent properties such as corrosion resistance, high temperature resistance and mechanical properties. It provides reliable and durable solutions for engineering design and meets the needs of various extreme working conditions.

High Temperature Resistance: Inconel 601 maintains good strength and oxidation resistance at temperatures up to 1200°C (2200°F), making it ideal for high temperature resistance heating applications.

Excellent Oxidation and Corrosion Resistance: The alloy has excellent oxidation resistance at elevated temperatures, especially in oxidising, sulphidising and carbonising environments, and Inconel 601 is able to form a stable oxide layer in environments with wide temperature fluctuations, preventing further corrosion.

Good Mechanical Properties: Inconel 601 maintains good mechanical properties not only at high temperatures, but also at low temperatures. This gives it an advantage in applications that require it to withstand both high and low temperature cycling.

Stability in Thermal Cycling: During repeated thermal cycling, Inconel 601 maintains good structural stability without embrittlement or cracking, which is especially important for long term stability of electric heating elements.

Feature:

High Temperature Performance: Inconel alloy wire has excellent high temperature performance, maintaining strength and stability in extreme temperatures. It can withstand environments such as high-temperature oxidation, high-temperature corrosion and thermal fatigue, and is suitable for applications that require working under high-temperature conditions.

Corrosion resistance: Inconel alloy wire has good corrosion resistance against a variety of corrosive media, including acidic and alkaline environments, seawater, chloride, sulfuric acid, etc. It is widely used in the chemical industry and marine environments for its corrosion resistance.

Mechanical properties: Inconel alloy wire has good mechanical properties, including high strength, high toughness and good ductility. This gives it excellent performance under high stress and load conditions, making it suitable for applications that need to withstand large forces and vibrations.

Welding performance: Inconel alloy wire has good weldability and can be used with various common welding methods, such as argon arc welding, resistance welding and laser welding. Proper welding process can ensure the strength and corrosion resistance of the welded joint.

Thermal expansion coefficient: The thermal expansion coefficient of Inconel alloy wire matches that of many metals and ceramic materials, allowing it to form reliable connections with other materials in applications and reduce problems caused by thermal expansion mismatch.

Manufacturing process: The production of Inconel alloy wire usually includes smelting, continuous casting, hot rolling, cold drawing and other processes. Understanding the principles and parameters of these manufacturing processes is crucial to optimizing the production process and improving product quality.

Standards and specifications: The production and application of Inconel alloy wire usually need to comply with some standards and specifications, such as ASTM (American Society for Testing and Materials) specifications, ISO (International Organization for Standardization) standards, etc. Understanding these standards and specifications can help ensure that products meet quality requirements and industry standards.

Physical property

Density: ρ=8.28g/cm3

Melting temperature range: 1393-1427℃

Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

Ni | ≥72 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

Shape | Size (mm) |

Wire | 0.5-7.50 |

Rod/Bar | 8.0-200 |

Strip | (0.5-2.5)*(5-180) |

Tube/Pipe | Customized |

Sheet/Plate | Customized |

For more details, pls directly contact us.

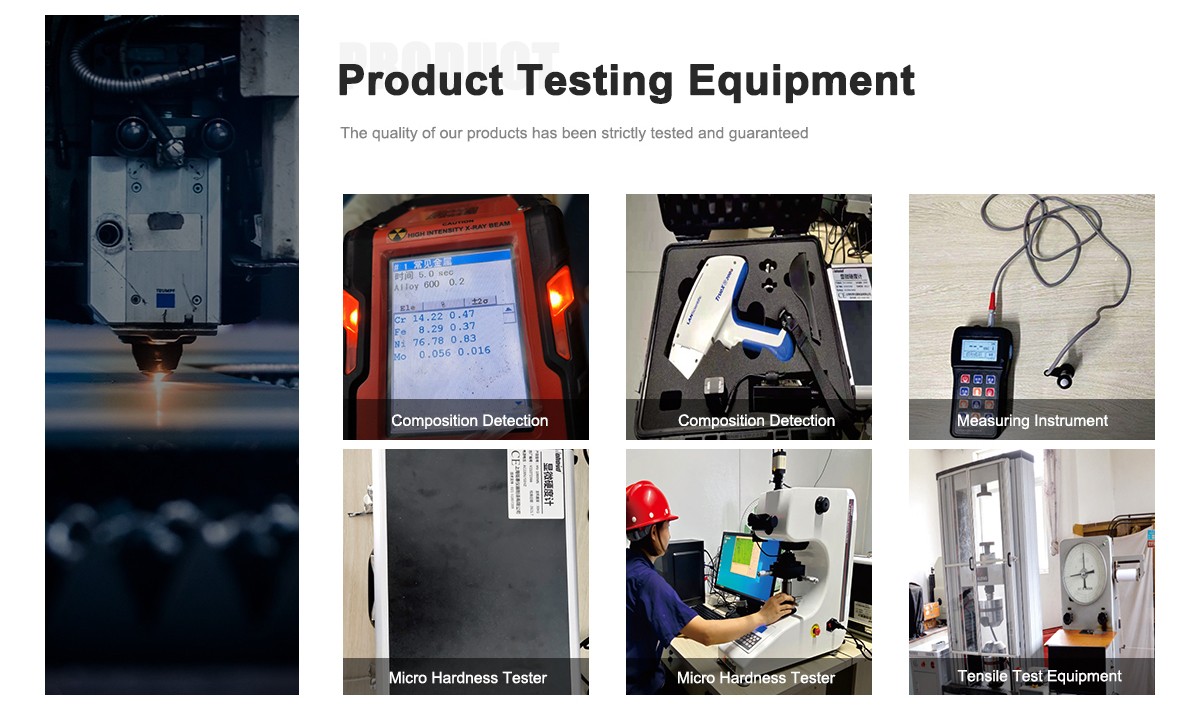

Quality Inspection

Quality testing of Inconel alloy wire is an important step to ensure that it meets expected standards and requirements. The following are some common quality inspection methods and techniques applicable to Inconel alloy wire:

Dimensional inspection: Use precision measuring tools such as micrometers, microscopes and optical projectors to measure and inspect the diameter, length and shape of Inconel alloy wire. This helps ensure that the alloy wire meets specified dimensional requirements.

Chemical composition analysis: Through chemical analysis methods, such as spectral analysis (such as photoelectric emission spectrum, photoelectric absorption spectrum), mass spectrometry analysis and chemical analysis, the chemical composition of Inconel alloy wire is detected and verified to ensure that its alloy composition meets standard requirements.

Mechanical property testing: Perform mechanical property testing on Inconel alloy wire, such as tensile testing, hardness testing and impact testing. These tests evaluate key mechanical properties of alloy wires such as strength, ductility and toughness.

Corrosion performance test: Evaluate the corrosion resistance of Inconel alloy wire in corrosive environments through corrosion performance tests, such as salt spray test, electrochemical corrosion test and corrosive medium exposure test. This is essential to ensure the long-term reliability of the alloy wire under specific operating conditions.

Non-destructive testing: Non-destructive testing technologies, such as ultrasonic testing, X-ray testing and eddy current testing, can be used to detect internal defects, cracks and unevenness in Inconel alloy wires. This helps eliminate potential quality issues and ensures the integrity of the alloy wire.

Detection Indicator

When testing the quality of Inconel alloy wire, the following are some common aspects and indicators that need attention:

Dimensions and geometric properties: including diameter, length, roundness, surface flatness, etc. These dimensional parameters need to comply with relevant standards and specifications to ensure that the alloy wire is suitable for the specific application.

Chemical composition: Analyze and detect the chemical composition of the alloy wire to ensure that its alloy composition complies with the specified requirements. Elements of concern include nickel, chromium, iron, titanium, aluminum, etc. These elements have an important impact on the performance of Inconel alloys.

Mechanical properties: including tensile strength, yield strength, elongation, hardness, etc. These performance parameters can be evaluated through tensile testing, hardness testing and other methods to ensure that the alloy wire has sufficient strength and plasticity.

Corrosion performance: Test and evaluate the corrosion resistance of alloy wires in specific corrosive media. Through salt spray test, electrochemical corrosion test and other methods, the performance and stability of alloy wire in corrosive environment can be understood.

Internal defects and quality defects: Use non-destructive testing technology, such as ultrasonic testing, X-ray testing, etc., to detect internal defects, cracks, impurities and other issues in the alloy wire to ensure the integrity and quality of the alloy wire.

E-mail: Info@hulkalloy.com

Mobile: 0086 13852926463

Tel: 0086 13852926463

Whatapps: 0086 13852926463

Add: Renli Village, Fangxian Town, Danyang City, Jiangsu Province, China